2006 Buell Lightning: Electrical 7-11

HOME

INSPECTION

1. Inspect spark plug cables. Replace cables that are worn

or damaged.

a. Check for cracks or loose terminals.

b. Check for loose fit on ignition coil and spark plugs.

2. Check cable boots/caps for cracks or tears. Replace

boots/caps that are worn or damaged.

NOTE

Both cables are the same length.

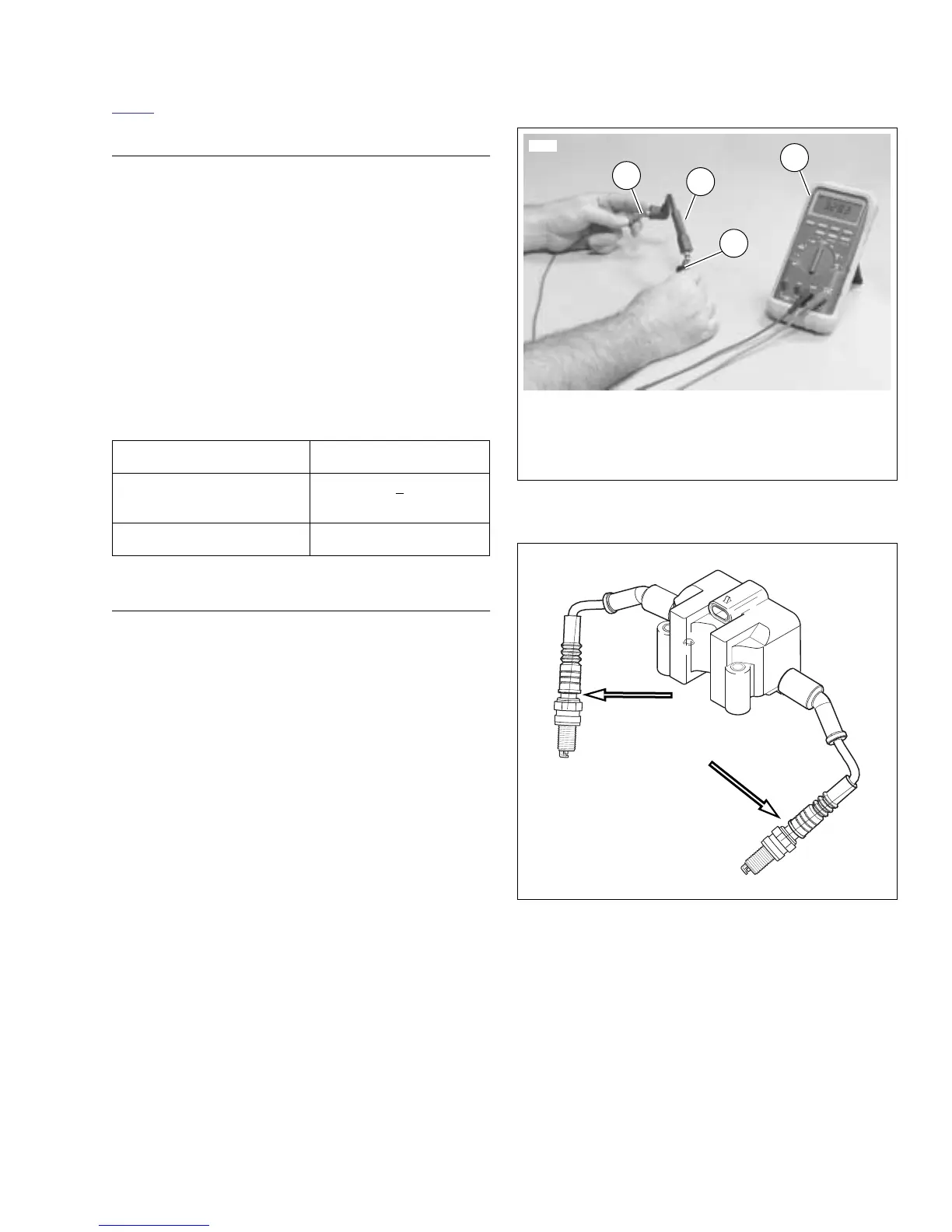

3. See Figure 7-9. Check spark plug cable resistance with

an ohmmeter. Replace cables not meeting resistance

specifications.

INSTALLATION

NOTES

●

To ease installation, install spark plug cables to ignition

coil first and apply ELECTRICAL CONTACT GREASE

(Part No. 99861-90) to the inside of spark plug boot.

●

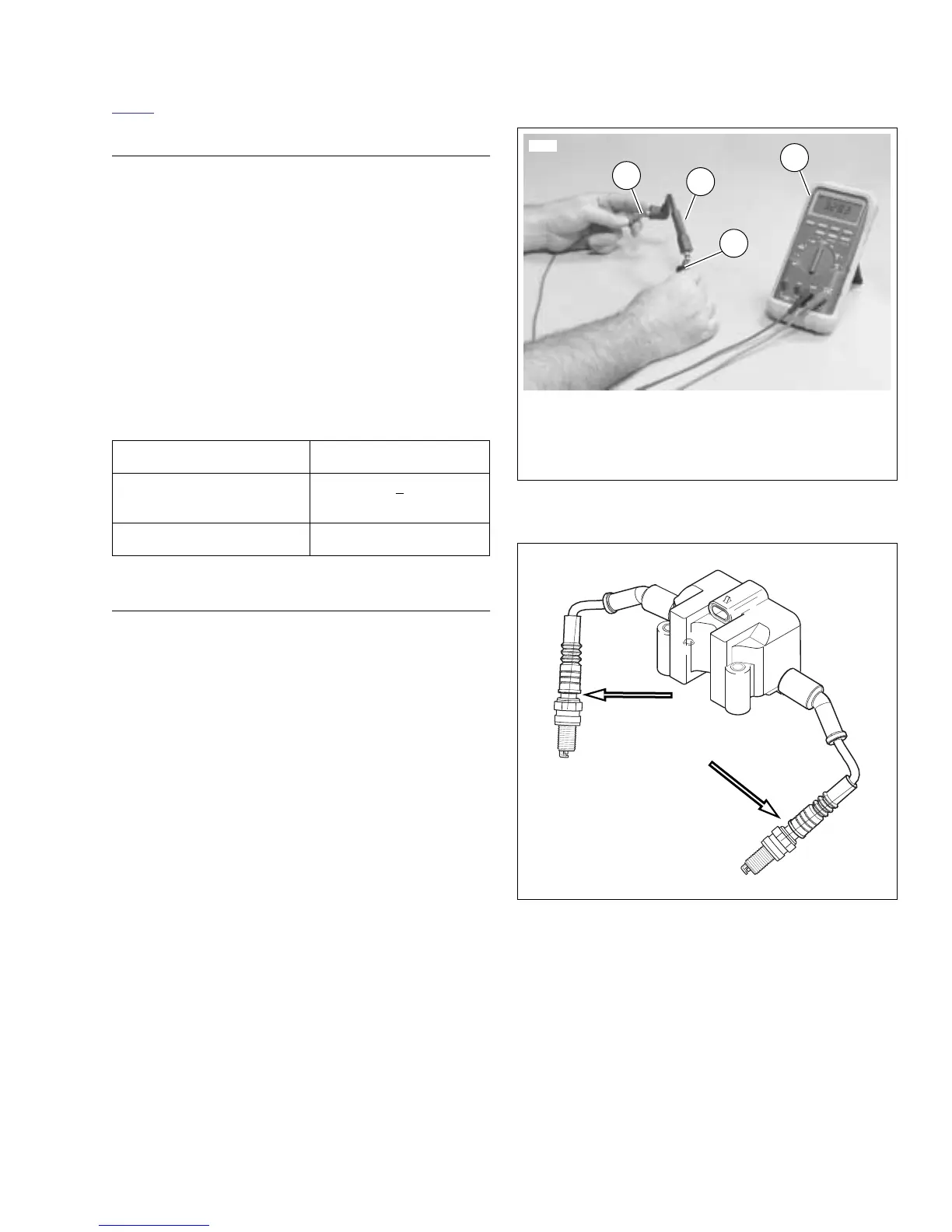

See Figure 7-10. When assembling the spark plug boots

onto the spark plugs, make sure the boot is slid all the

way down over the spark plug insulator. The gap should

not exceed 1/8 in. (3.2 mm).

●

For spark plug information see 1.13 SPARK PLUGS.

1. Connect spark plug cables to ignition coil and spark

plugs. Fasten boots/caps securely. Tight connections

provide the necessary moisture-proof environment for

the ignition coil and spark plug terminals.

2. Install air cleaner assembly. See 4.44 AIR CLEANER

ASSEMBLY.

Table 7-10. Spark Plug Cables

SPECIFICATION FRONT & REAR

Length - in. (mm)

5.70 +

0.25

(145)

Resistance - Ohms 1,350-3,465

Figure 7-9. Testing Resistance

Figure 7-10. Boot Gap Should Not exceed 1/8 in. (3.2 mm)

Loading...

Loading...