Chapter 2 BK730-2 Base Page 2-6

2.1.9.4 Photo F/B receptacle

This receptacle is connected to the front and back photo sensors on the transport base. It

is connected to the head Photo F/B receptacle using cable P/N 9101659A.

2.1.9.5 Jam Receptacle

This receptacle is connected to the base jam switch and the upper transport sensor. It

must be connected for the Tabber/Labeler to function. It is connected to the head jam

receptacle using cable P/N 9101660A.

2.2 Upstream and Downstream Installation Instructions

The upstream and downstream installation instructions comprise all the information

necessary to properly integrate the Tabber/Labeler system with upstream and downstream

equipment such as inkjet systems, feeders, flipover units, and conveyors. Essentially there

are two steps to a successful integration. They are proper alignment of the base with the

upstream and downstream equipment for proper material handling and integration of the

electrical system via the Base Control Board (p/n 9102380) to coordinate the control of all

equipment in the system. Note that the proper interconnect cable, listed in Table 2-1, must

be used depending on the system’s configuration.

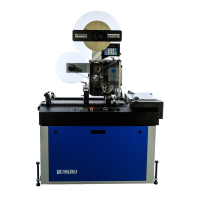

Table 2-1: BK730-2 Upstream/Downstream Integration

Upstream Downstream Cable Required (Buskro P/N)

BK425 (Shuttle Feeder)

BK460 (Inline Base – Series 4)

BK660 (Inkjet Base)

BK76IB

BK7IB (Inline Base – Series 7)

BK730-2 9102083A

BK730-2 (Tabber/Labeler) BK460

BK730-2

BK76IB

BK7IB

9102083A

BK720 (Friction Feeder) BK730-2 9101814A

2.2.1 Physical Alignment of Upstream/Downstream equipment

These instructions describe the physical alignment of the tabbing system with upstream or

downstream equipment:

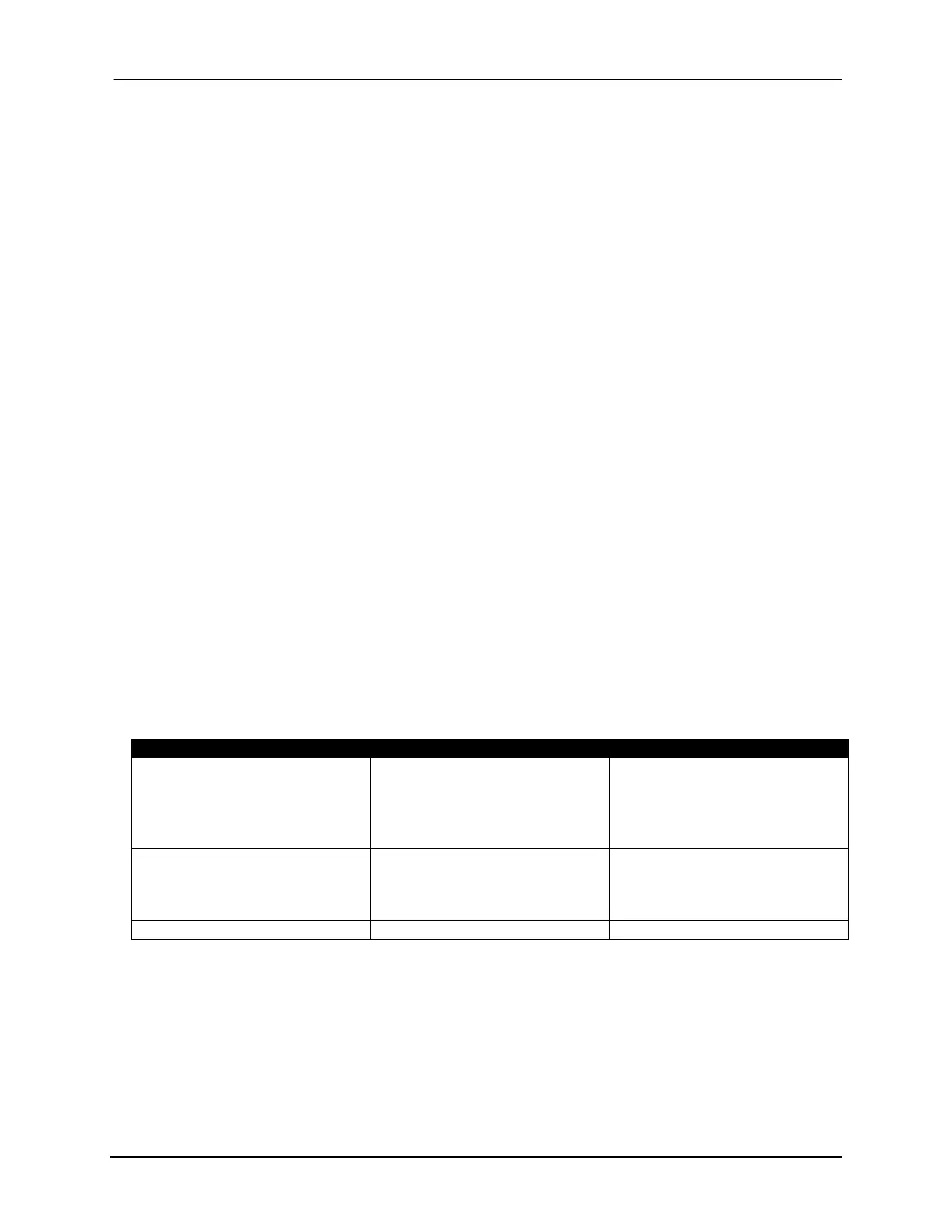

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...