Chapter 2 BK730-2 Base Page 2-22

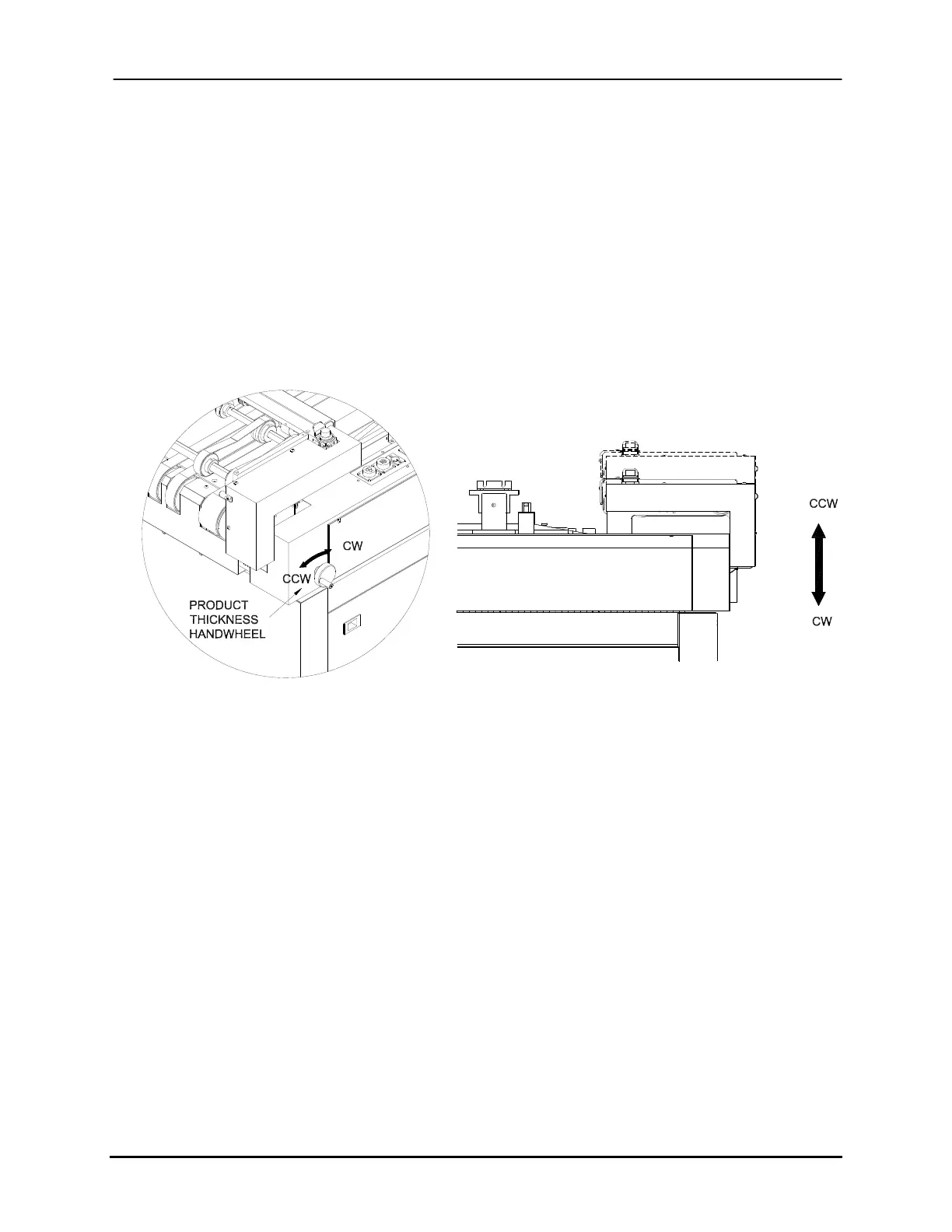

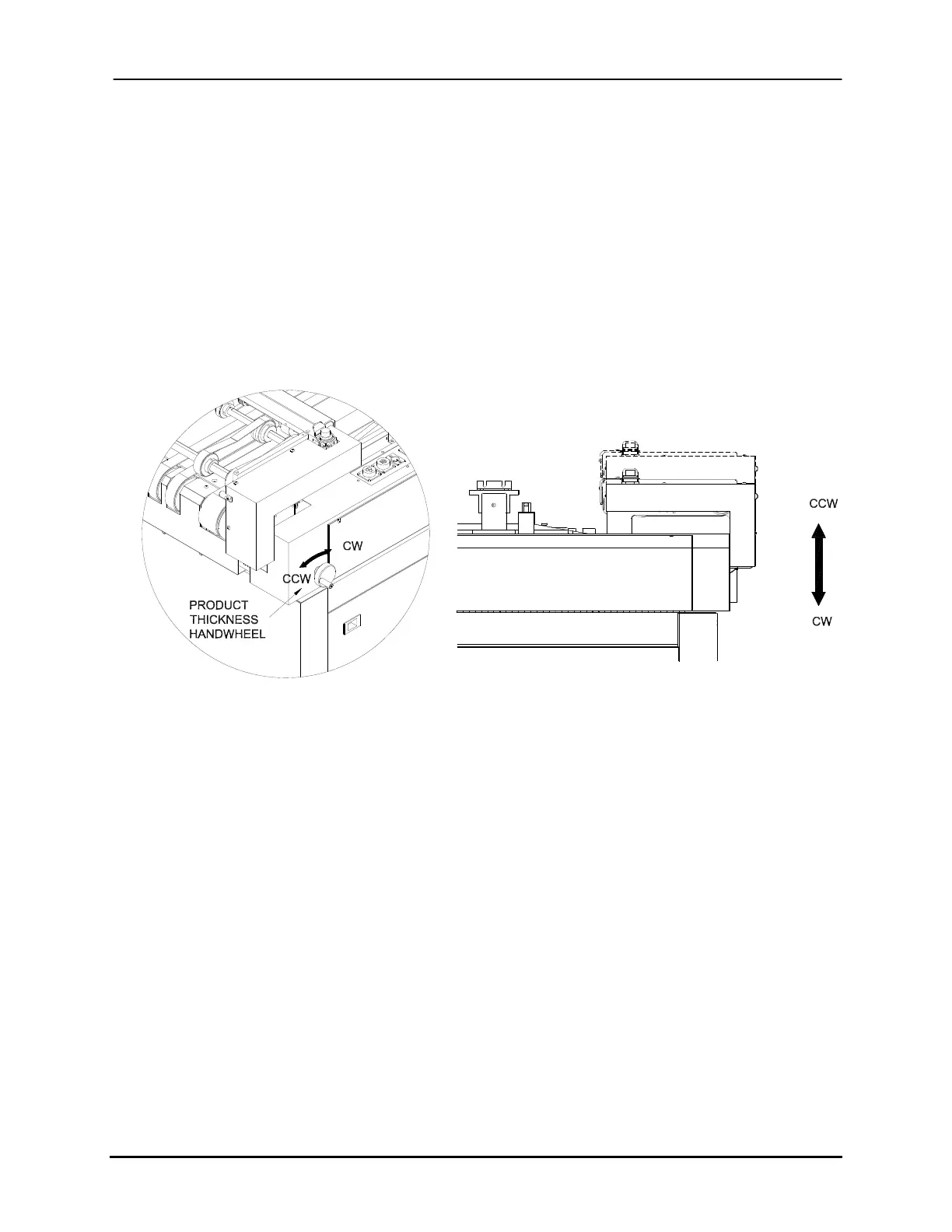

2.3.3 Product Thickness Adjustment (Upper Transport)

When feeding a new product, it may be necessary to adjust the upper transport assembly

and the Tabber/Labeler head peel point assembly to accommodate the product’s thickness.

Adjustment to the upper transport is made by rotating the product thickness handwheel

(Figure 2-10). The tabbing head peel point assembly also needs to be moved up or down

to accept different product thickness. Proper thickness adjustment will ensure that the

product is tabbed and conveyed in the tab-wrap section without skewing.

Figure 2-10: Product Thickness adjustment

In order to adjust the height of the upper transport:

1. Close the upper transport (it should be latched in place).

2. Raise the upper transport assembly sufficiently to allow free passage of the

product by rotating the product thickness handwheel counter-clockwise (CCW).

3. Place the product between the upper transport assembly’s outfeed rollers and the

table belt outfeed rollers.

4. Lower the upper transport assembly such that the product is snuggly held between

the rollers in step 3. Do this by rotating the product thickness handwheel in a

clockwise (CW) fashion. Perform a test by pulling the mailpiece to see if it is

snuggly held. Be careful not to put too much pressure on the mailpiece because it

can cause the upper transport belts to fall off the rollers or product skew.

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...