Chapter 3 Mechanical Adjustments Page 3-8

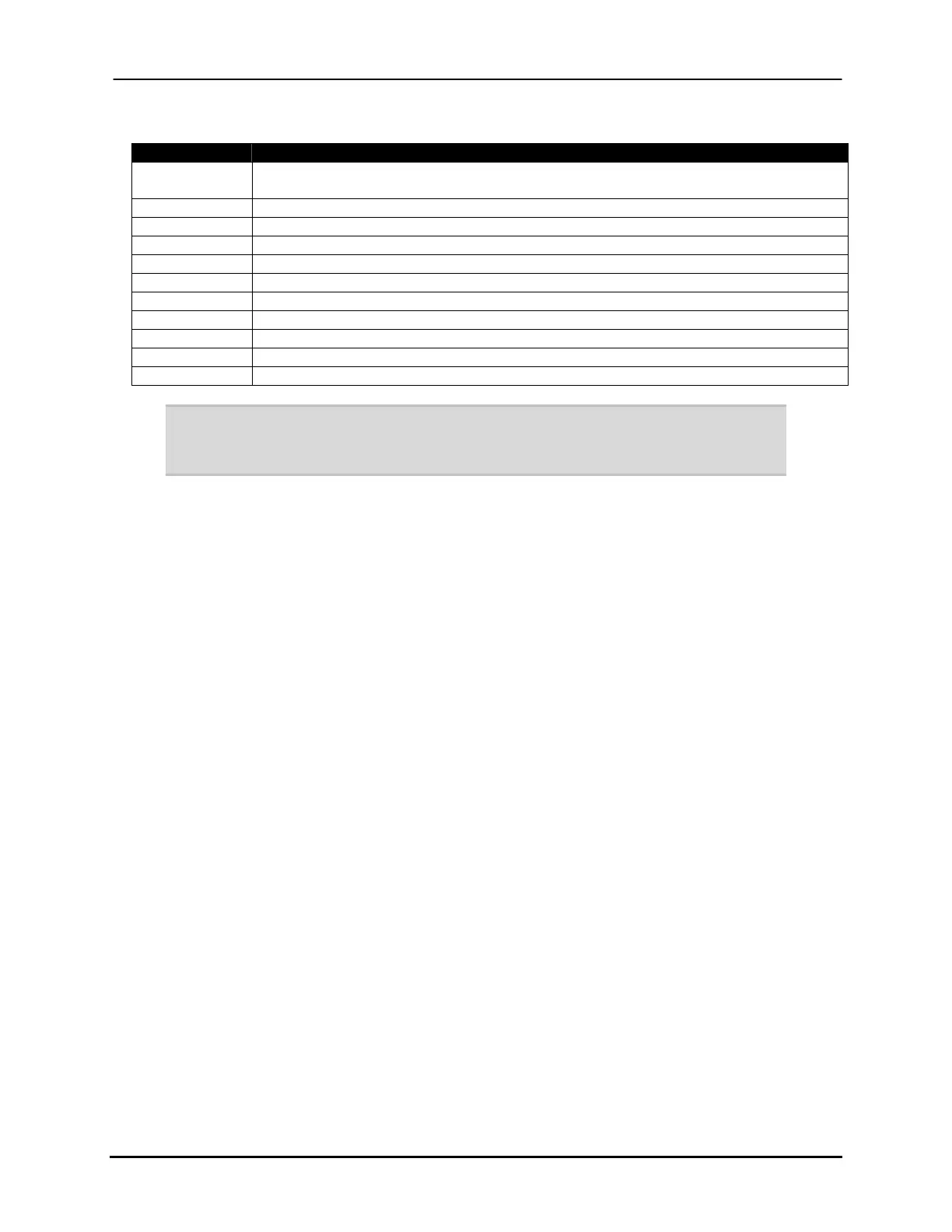

Table 3-1: Labeler Connector Panel Functions

Connector Function

Output Provides output signals (stop relay uses pins 1 and 2). Requires Connector

(614125), contacts (614108), and cable clamp (614126).

Product Connection for Photocue sensor (Reflective, Through-Beam, or Diffuse).

Jam Connection for Jam switch

Inhibit Used for future designs

Comm Used for future designs

Power Incoming Power (115 VAC)

Encoder Connection for Encoder sensor

Photo F/B Used on the BK730 base (for front and back Through-Beam sensors)

Tab Connection for Tab Sensor in the Peel Point

Keypad Connection for the Labeler Keypad

Controller I/O Connection for Labelers mounted on a BK7IB

Note: The Product and Photo F/B cables cannot be connected simultaneously. One of

these inputs is used in order to trigger the presence of materials on the transport

base whether it is a BK730A-2 or third party equipment.

3.3 Wide Labeler Guidelines (BK731-2WL & UBK-731-WL)

This section provides guidelines for applying labels with backer materials up to 5” (127

mm) onto mail substrates such as envelopes and magazines. These tips apply for all Wide

Label Systems including normal BK731-2 labeling heads that have been upgraded in the

field via the UBK-731-WL field upgrade kit.

3.3.1 Importance of the Right & Left Side Guides

One of the critical requirements for Wide Label Tabber applications is to ensure that the

mail piece or magazine being labeled does not skew in any direction before the label is

applied. If the substrate does approach the Wide Label Peel Point Assembly (p/n

9103815A) at an angle, the applied label will also have a skew angle and its edges will not

be parallel to that of the substrate. Furthermore, if each piece is transported with slightly

different angles, there will be a significant piece-to-piece drift for the applied label

position. This is due to the fact that the signal that determines when the label application

process should begin is based on lead edge detection of mail pieces. Different angles with

respect to the Right and Left Side Guides (p/n 212430 and 212431) for transported mail

pieces can delay or accelerate detection of the physical mail piece resulting in inconsistent

label positioning.

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...