Chapter 3 Mechanical Adjustments Page 3-12

Excessive wear is defined as significant changes in the diameter of the pressure roller

resulting in unacceptable labeling/tabbing performance.

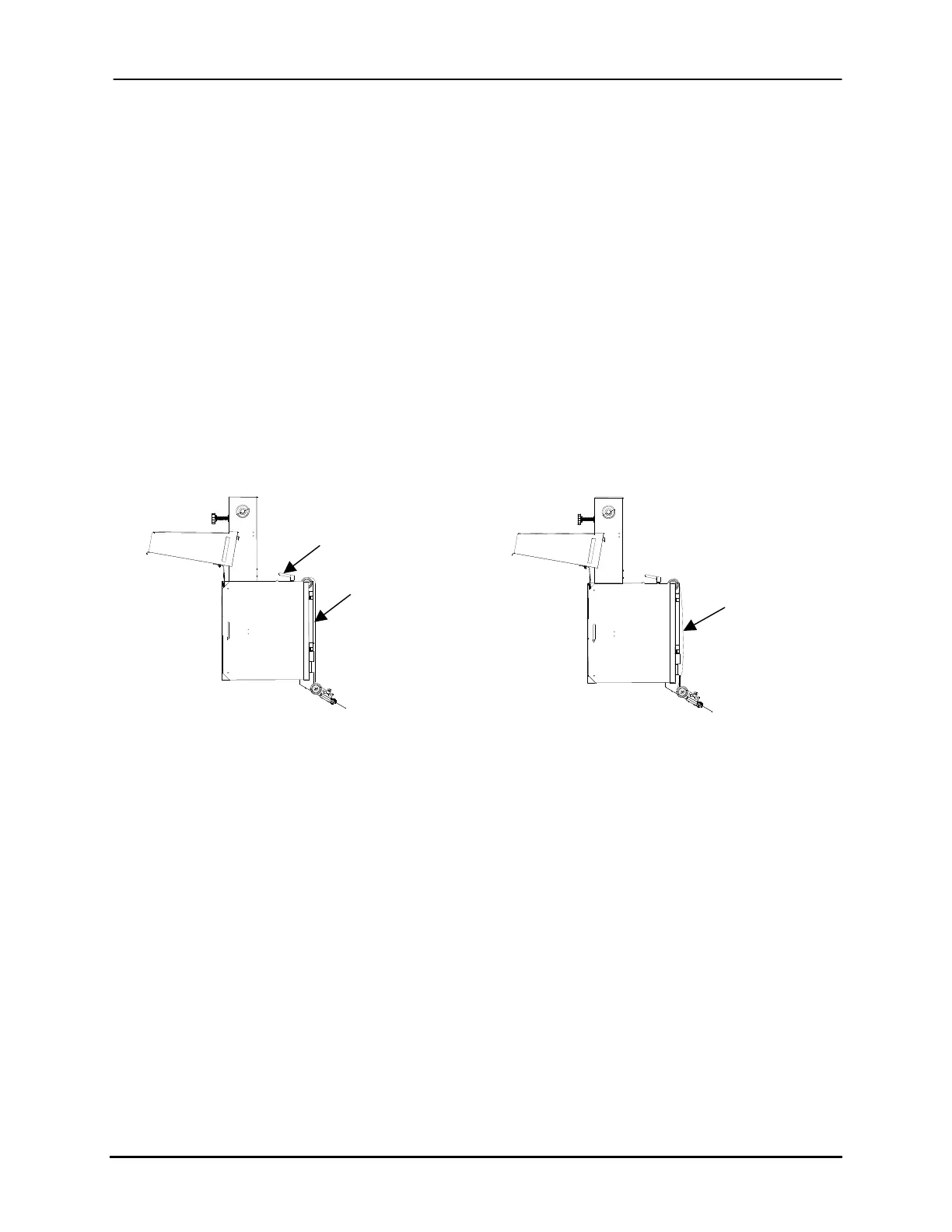

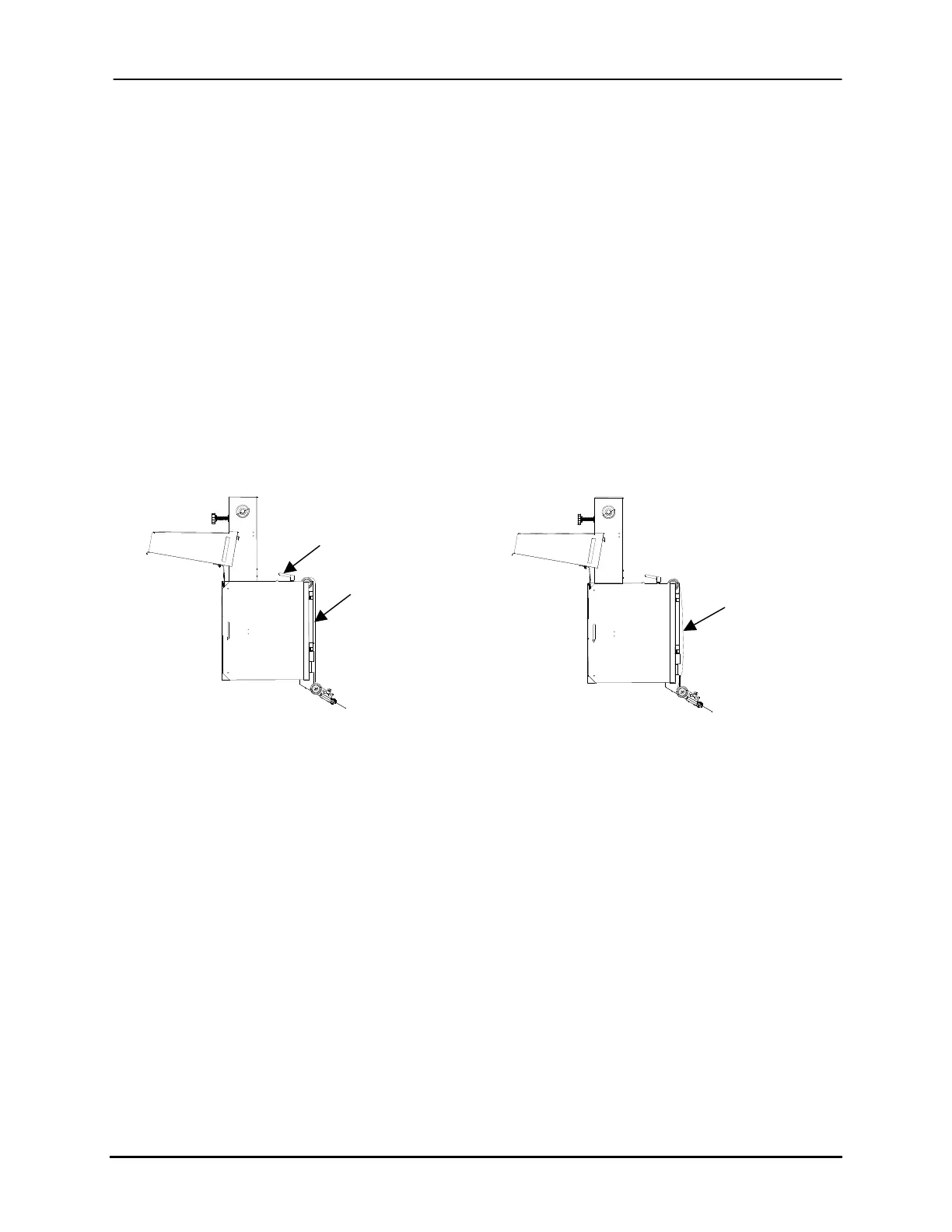

3.3.4 Label Backer Tension

The tension of the label backer material in the section between the Wide Label Tabber

Storage Bin (p/n 9103807) and the Wide Label Peel Point Assembly (p/n 9103815A) must

be taut. This is accomplished by adjusting the pressure on the label backer material using

the Brush Pivot Assembly (p/n 9103816A). Illustrations of proper and poor setup of the

label backer material tension are shown in

Figure 3-10.

Figure 3-10: Label Backer Material tensioning setup.

If it is determined that insufficient tension is present, the following steps should be

performed to readjust the backer material:

PROPER POOR

¼-20 UNC

Lever Handle

/n 206010

If backer material is

loose it will result in

inaccurate label

placement

Backer Material

must be taut

1. Loosen the ¼-20 UNC Lever Handle (p/n 206010) and back off the Brush Pivot

Assembly, WL (p/n 9103816A).

2. Adjust the label backer material so that it is taut as shown in Figure 3-10.

3. Reposition the Brush Pivot Assembly and tighten so that it is applying pressure

onto the label backer material.

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...