Chapter 4 User Interface Page 4-3

4.2.2 Adjustment of the Product Sensor Position

The Product Sensor Position (PS POS) indicates the distance from the photo sensor to the

tip of the peel point. This setting affects the position of the label being placed onto the

product. An incorrect setting will result in inaccurate placement of the label on the

product. This value must be changed to match the location of the photo sensor. This can

be accomplished by completing the following:

1. If the keypad does not say “OFFLINE”, press the <Online> key.

2. Press the <Setup> button. Press the Down button until the display reads “PS

POS: ##. ###” (where ##.### indicates the current position).

3. Using the keypad, enter in the distance (in inches) the center of the product sensor

is from the tip of the peel point (where the label is released) and then press

<Enter>. It is also possible to press <+> or <-> to increment this value by ±1/8”.

4. Press <Online> to exit the Setup menu.

Note: The factory setting for the product sensor location is 6.25”. The BK731-2 head

allows for values between 1 to 40 inches. However, it is recommended that the

sensor be as close to the peel point as possible to avoid the possibility of the

product moving out of position or slipping after passing the photo sensor.

4.2.3 Production Counter Resetting

The production counter indicates the number of pieces labeled in a given job. In order to

reset this value after a job is complete, the following steps must be completed:

1. If the keypad does not say “OFFLINE”, press the <Online> key.

2. Press the <Setup> button. Press the Down button until the display reads “RESET

COUNT <+++>”.

3. Press <+> button three times. The head should beep and reset the counter.

4. Press <Online> to exit the Setup menu.

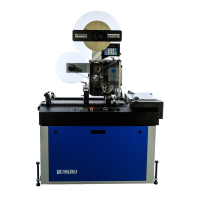

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...