Chapter 2 BK730-2 Base Page 2-17

If the Base is a Feeder, and Gap Control is the desired operating mode, turn

S3 Position 5 on with all others off.

If the base is the last transport in the system turn S3 Position 8 on with all

others off.

If the base is other than the last transport in the system turn S3 Position 4

on with all others off.

2.3 Product Setup Instructions

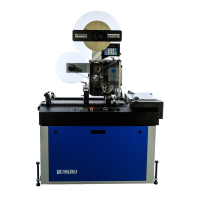

The product setup instructions must be followed in order to ensure smooth product flow

and tab-wrap quality. Included is information pertaining to the lateral positioning of the

BK730-2 table for edge selection, adjustments for various product thickness, setting of the

skidbar for smooth product conveyance, and upper transport height adjustment for

excellent tab wrapping results. In addition, the instructions will cover the setting of the

relative transport speed to ensure smooth product transfer between the BK730-2 and the

upstream system.

All tabbing head mechanical adjustments and control settings will be covered in Chapter

3.0. These instructions will cover the mechanical positioning of the tabbing head, tab

spool threading, leveling the tabbing head, and tab application.

2.3.1 To adjust the base speed for smooth product transfer

In order to prevent product buckling at the entry of the BK730-2 transport, it is important

that the BK730-2 speed be slightly faster than the upstream delivery equipment. As a

result, set the BK730-2 transport base so that it is slightly faster than the transport speed

of the upstream equipment. In addition, ensure that the gap between the product pieces on

the transport base is between 1 to 2 inches (25 to 50 mm). If the gap is too small, it may

result in inconsistent tabbing and may result in unnecessary product jams.

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...