Chapter 4 User Interface Page 4-5

4.2.7 Form Size Error

The Form Size Error feature is used to verify the length of the product being conveyed for

any given job. If the Labeler has been setup to run a 30,000 piece job running 9.5” long

envelopes, when enabled, the Form Size Error will monitor the length to ensure that each

piece is in fact 9.5” long. This is accomplished by monitoring the speed of the transport

base and the amount of time that the product sensor is triggered. When an unexpected

length is calculated from these parameters with respect to the setup length, a stop signal is

generated. This feature is helpful for detecting skew of materials during transport or a

change in material length. With this feature disabled, product skew and variation in

lengths are ignored during normal tabbing/labeling and may cause a problem for label/tab

placement especially if the lead edge of the product is skewing. The following

instructions detail how to setup the head for Form Size Error detection:

1. If the keypad does not say “OFFLINE”, press the <Online> key.

2. Press the <Setup> button. Press the Down button until the display reads “SIZE

ERROR: ######”.

3. Press the <+> button to switch between the “ENABLED” or “DISABLED”

options depending on how you would like to operate the Labeler.

4. Press the <Enter> key to save your selection.

5. Press <Online> to exit the Setup menu.

4.2.8 Displaying Metric Units on the Operator Keypad

There now exists the option to display the product sensor position, label spacing positions,

product length, and label pitch in metric [cm] or imperial [in] units. Perform these

instructions to configure your Labeler as desired:

1. If the keypad does not say “OFFLINE”, press the <Online> key.

2. Press the <Setup> button. Press the Down button until the display reads

“UNITS: ######”.

3. Press the <+> button to switch between “METRIC” or “IMPERIAL”.

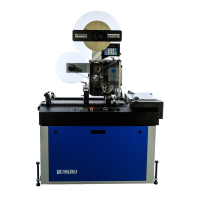

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...