Chapter 3 Mechanical Adjustments Page 3-10

sealing zone. If there is insufficient pressure, the material may also simply stop moving

and get stuck on the tabletop. Alternatively, with a lack of consistent pressure along the

entire length of the Skidbar Assembly, the substrate can slip and skew which will result in

inaccurate label placement.

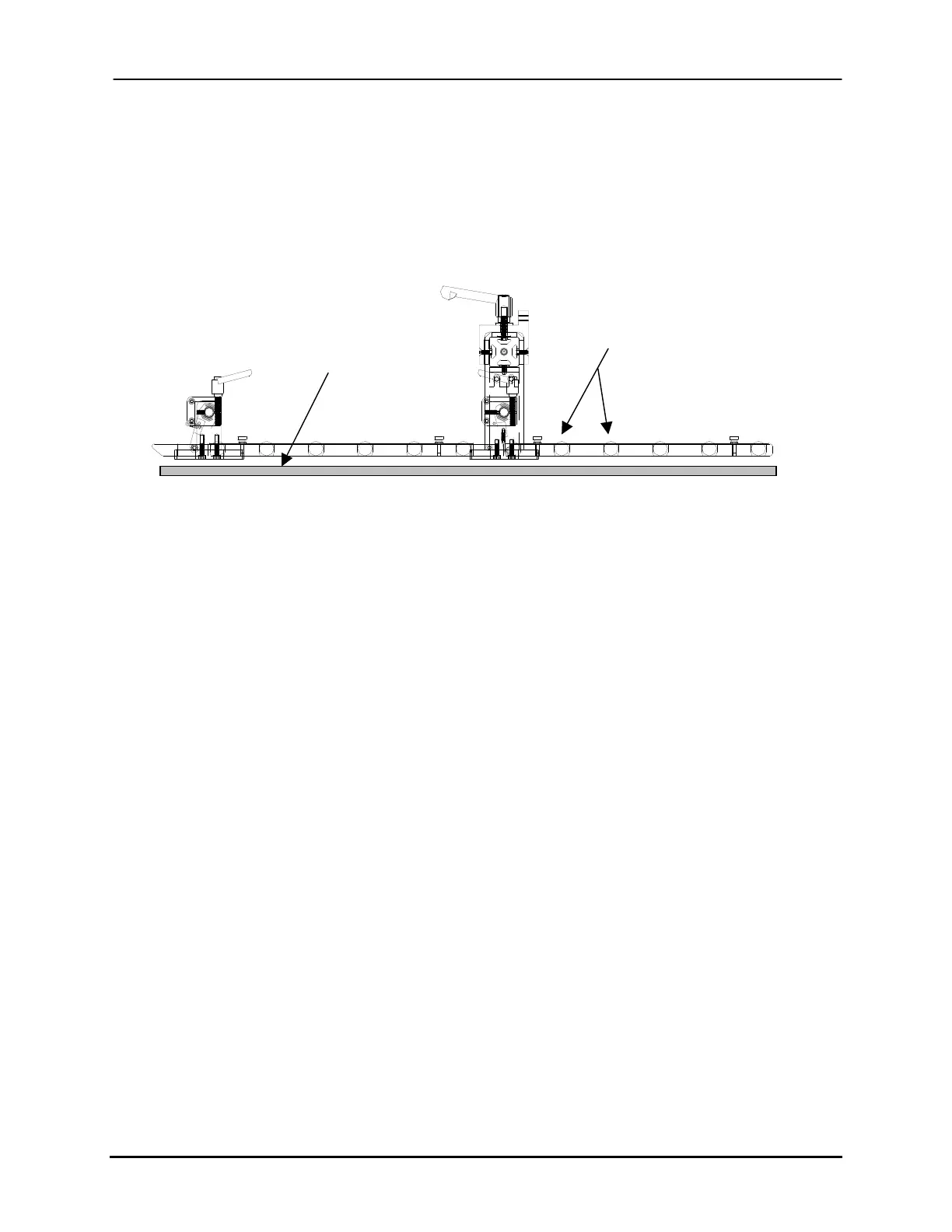

Figure 3-8: Tabber Skidbar Assembly side view.

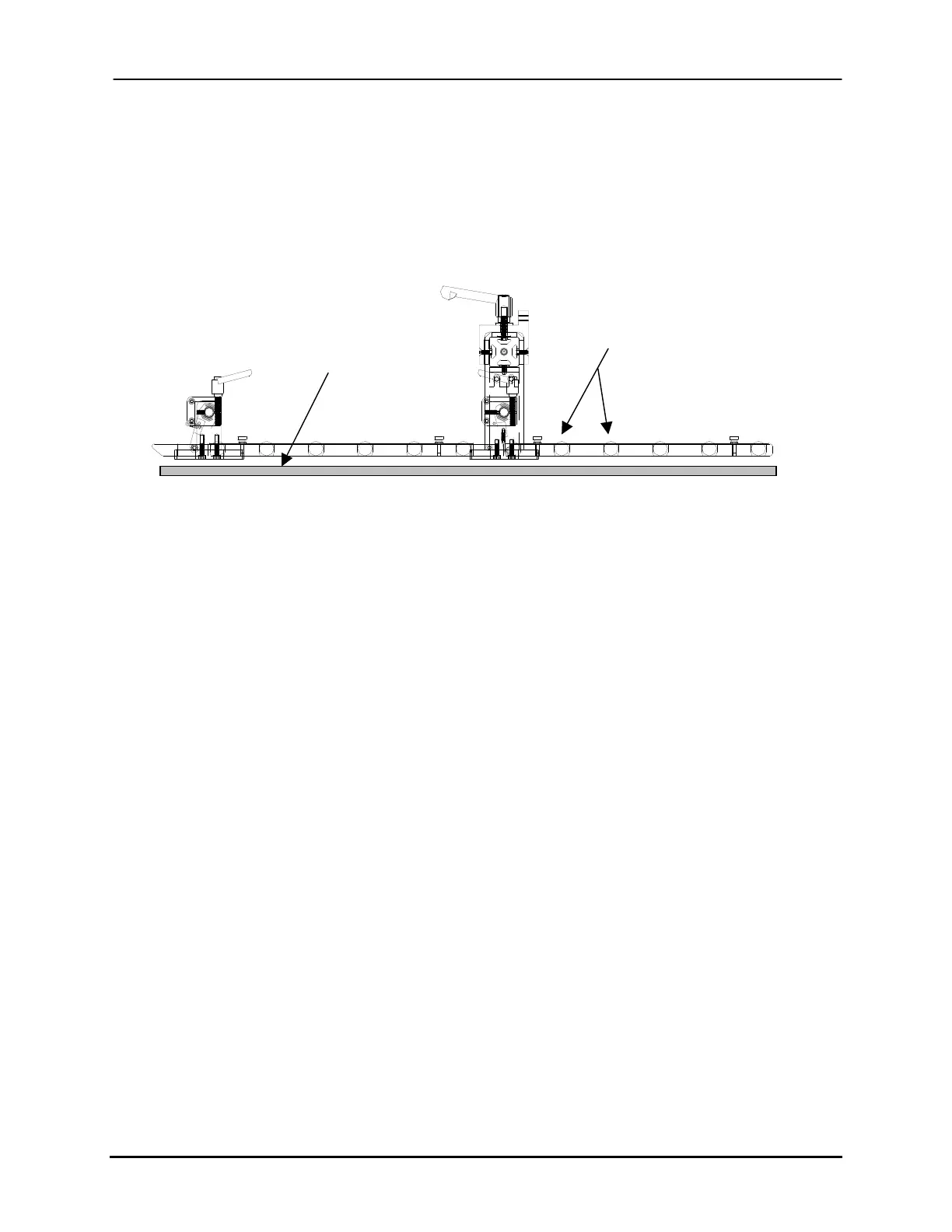

If the spacing between the tabletop surface and the ball bearings is not equal along the

entire length of the skidbar, the Skidbar Assembly must be adjusted. There are four

support blocks (p/n 9101059) with machined oblong cutouts that allow for adjustments to

be made to the position of the Skidbar. By loosening the mounting screws shown in

Figure 3-9 and pushing on one of the Skidbar Brackets (p/n 330302), the level of the

Skidbar Assembly can be set to have an equal gap between the tabletop and the bottom

surface of the Skidbar Assembly. The mounting screws for the brackets should be

tightened once the correct setup is achieved. Double-check for a consistent gap between

the Skidbar Assembly and the tabletop once all the screws have been tightened.

UPSTREAM SIDE

Ball Bearings

DOWNSTREAM SIDE

Tabletop

Buskro Ltd. BK730-2 Tabber

Loading...

Loading...