3.1.13-178

CS35 2013.04

3.1.13-178Electronic Control System - ME7

DTC P0321, P0322

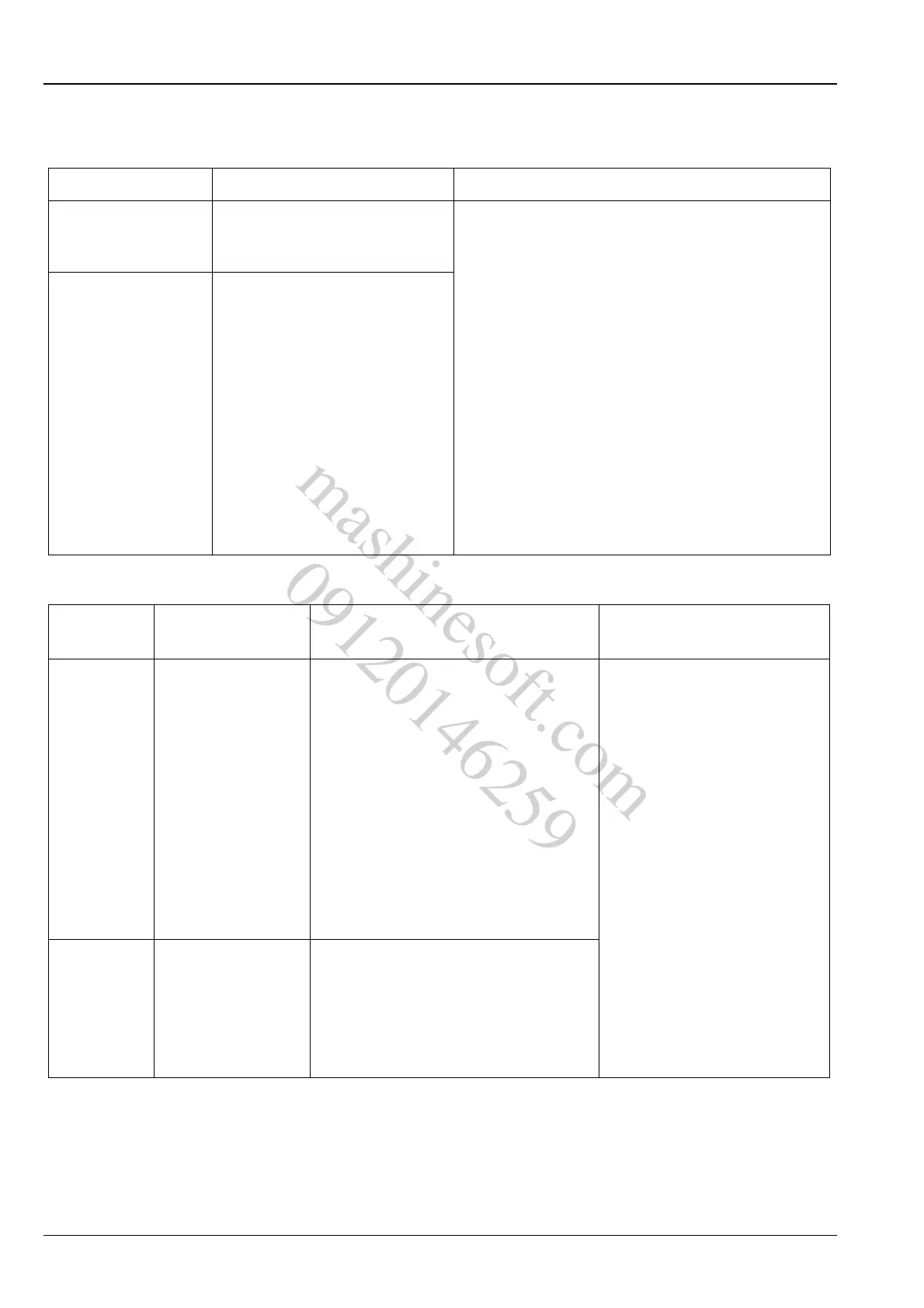

1. DTC Description

2. Possible Sources

Fault Code Description Definition

P0321

Crankshaft upper dead point

missing teeth signal unreason-

able

Crankshaft upper dead center signal fault. CKP sen-

sor signal tells ECM the speed and position of cur-

rent crankshaft CKP sensor produces an alternating

voltage with different amplitude and frequency. Fre-

quency is decided by crankshaft speed and output

alternating voltage is decided by CKP. CKP sensor

cooperates with crankshaft's last retaining 58X vari-

able reluctance rotor. ECM can calculate ignition

timing, injection timing and knock ignition control

according to input signal of CKP sensor and cam-

shaft position sensor. CKP sensor is used for

inspection of misfire and tachometer display. ECM

transmits engine speed signal to instrument via CAN

network. CKP sensor signal is connected to termi-

nals 15, 34 of ECM wiring harness connector E01

respectively via terminals 1, 2 of CKP sensor wiring

harness connector E07.

P0322 Speed sensor signal fault

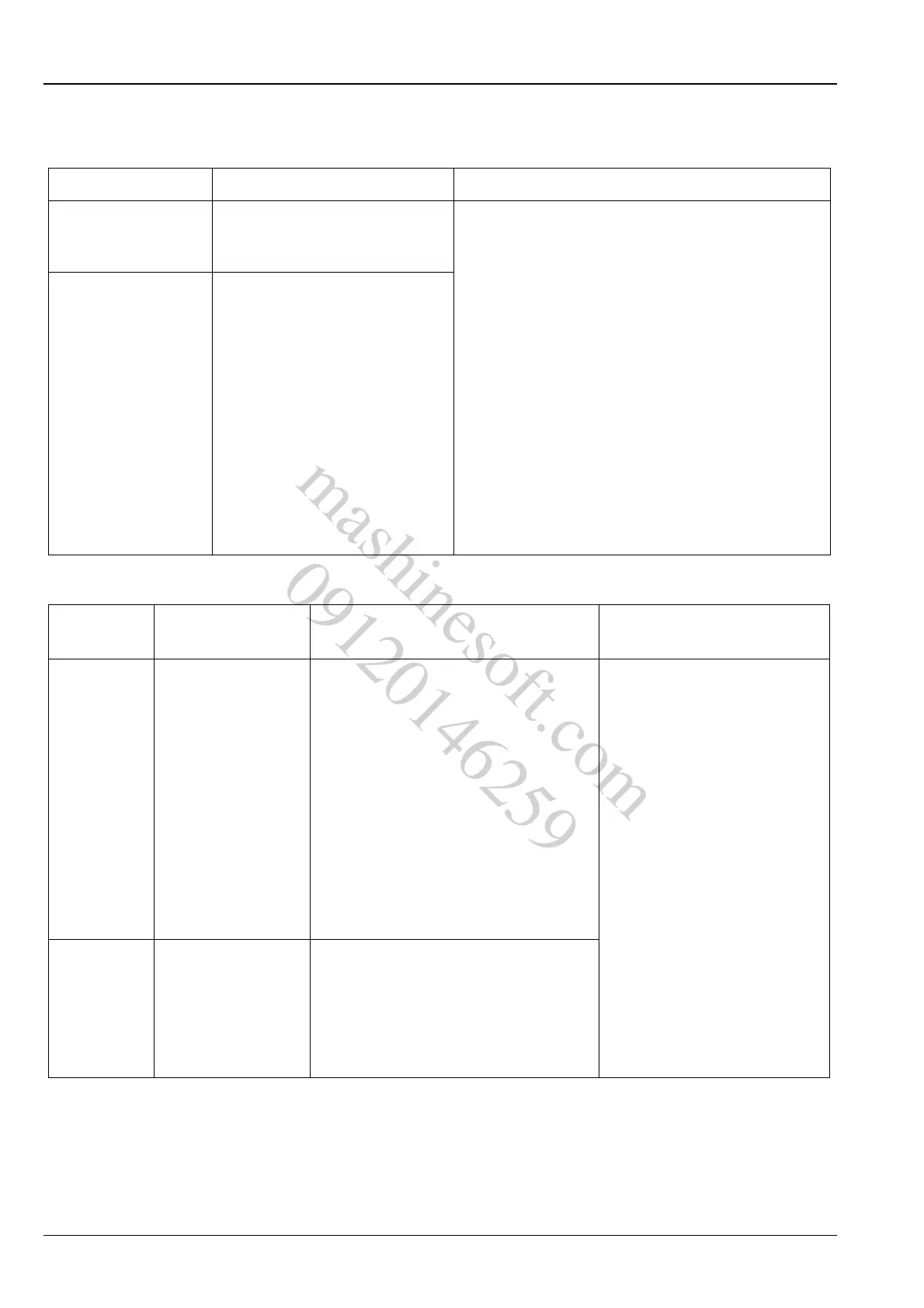

Fault

Code

Test Tactics

Setting Conditions (Control

Strategy)

Fault

P0321

• Frequent correc-

tion to increase

tooth

• Frequent correc-

tion to decrease

tooth

• Speed sensor sig-

nal exist but the

reference mark

can not be found

• Frequently lost

reference mark

• Increase one tooth correction numera-

tion time is bigger than 250

• Decrease one tooth correction

numeration time is bigger than 250

• Unmonitored reference mis - tooth

numeration time 4 is bigger than 6

• The correction numeration time of the

lost reference mis - tooth is more than

2,000

• Crankshaft position sensor

fault

• Crankshaft position sensor

circuit fault

•ECM fault

P0322

After a certain num-

ber of camshaft

position

sensor signal, no

crankshaft position

signal is monitored

• Phase signal register value is higher

than 18

• Relative low speed engine group

speed

mashinesoft.com

09120146259

Loading...

Loading...