Secon 10 - Diagnosc and Maintenance Procedures

10.3.3 Draining down the Espresso Boiler

Draining down the module allows the engineer to safely work on system components. It may

also be necessary to do this for transit purposes.

Note: A CoEx® Boiler Cool Down cycle MUST ALWAYS be carried out before draining

the espresso boiler.

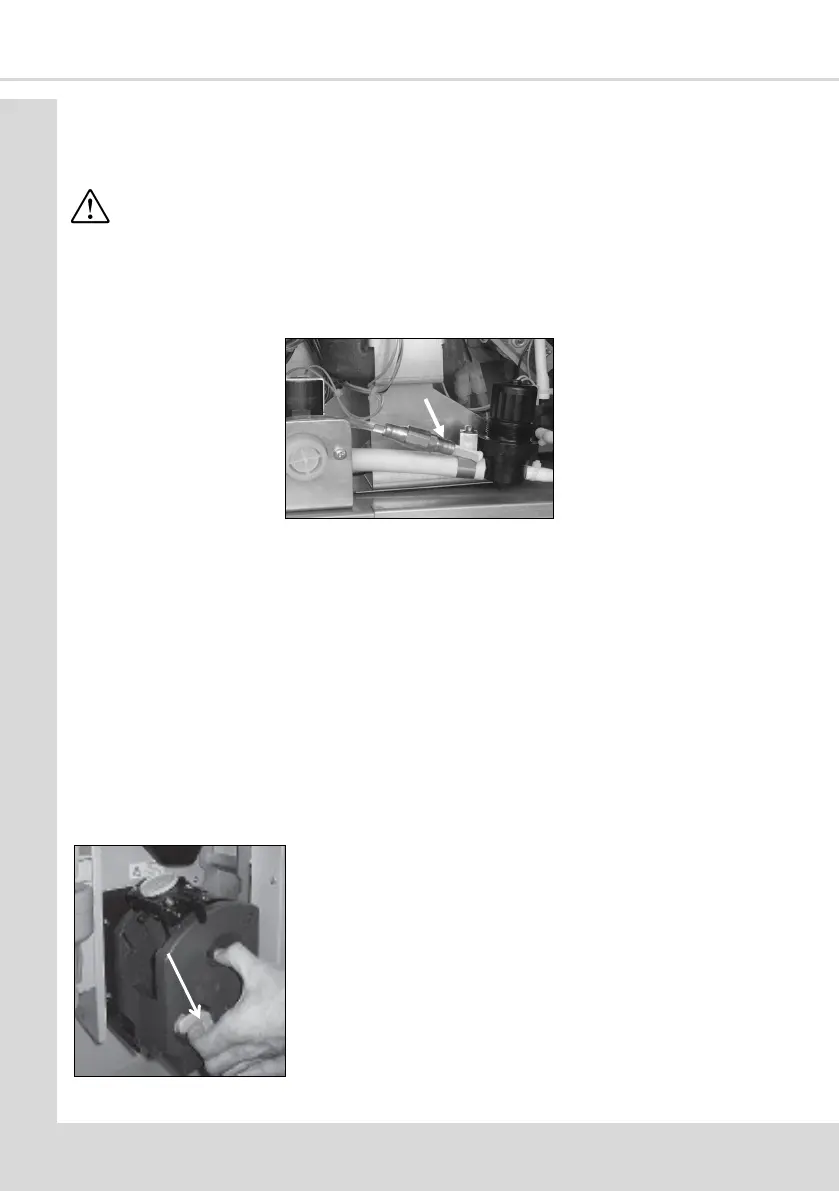

1. Remove the lower cover from the module to expose the boiler blanking plug (1). Hold

the collar and remove the plug. You must also break into the water circuit above the

boiler by disconnecng any of the connecons to allow the water to drain. A length of

silicone pipe aached to the outlet can be used as a drain tube.

2. Reverse the procedure before pung the module back into service.

10.4 CoEx® Brewer/Bean Grinder Maintenance

Espresso machines are ed with the CoEx® brewer unit which produces both fresh coee

and espresso based drinks from ground beans and freshbrew pre-ground coee from the

same unit. Roune cleaning and maintenance instrucons for this unit can be found in the

Operator’s Manual

10.4.1 CoEx® Brewer/Grinder Blades - 50,000 Vend Service

Crane Merchandising Systems recommends that the brewer unit and bean grinder are

serviced by an authorised engineer aer every 50,000 vends.

To carry out the 50,000 vend service, proceed as follows:

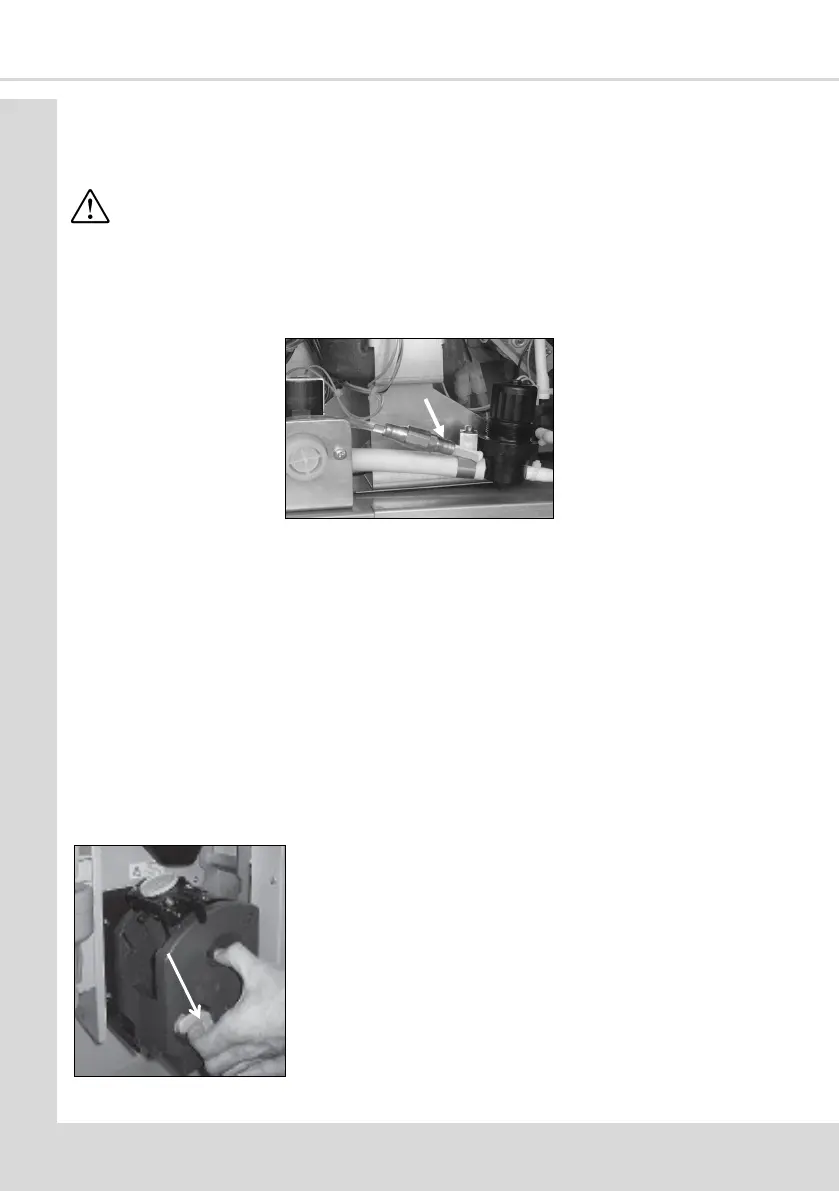

1. Disconnect the machine from the mains electricity.

Open the front door of the machine and remove the

coee dispense pipe from the brewer outlet.

Holding the unit as shown in the photograph, li the

green lever (a) and carefully pull the brewer unit out of

the machine.

2. Carefully unclip the wiper arm from the brewer unit and

place to one side.

1

a

Loading...

Loading...