Secon 10 - Diagnosc and Maintenance Procedures

Technical Manual

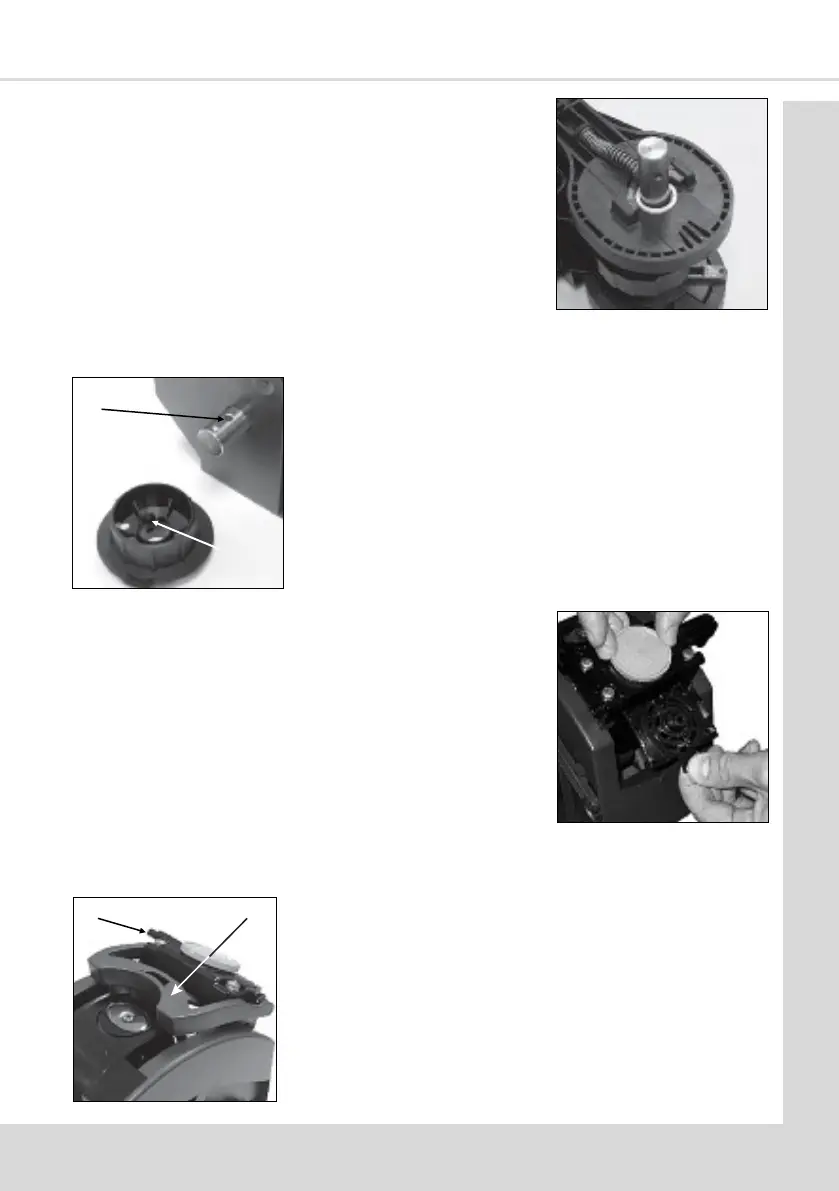

13. Take the new lter head assembly from the service kit.

Holding the new lter assembly as shown, turn the

locking ring an-clockwise to its open posion,

indicated by the two arrows.

Place the lter unit up into the lter holder and turn the

green locking ring clockwise to lock it into place

14. Re-assemble the wiper arm (d) to the lter holder

assembly.

Ensure that the wiper arm is located under the coee

outlet pipes as shown (e).

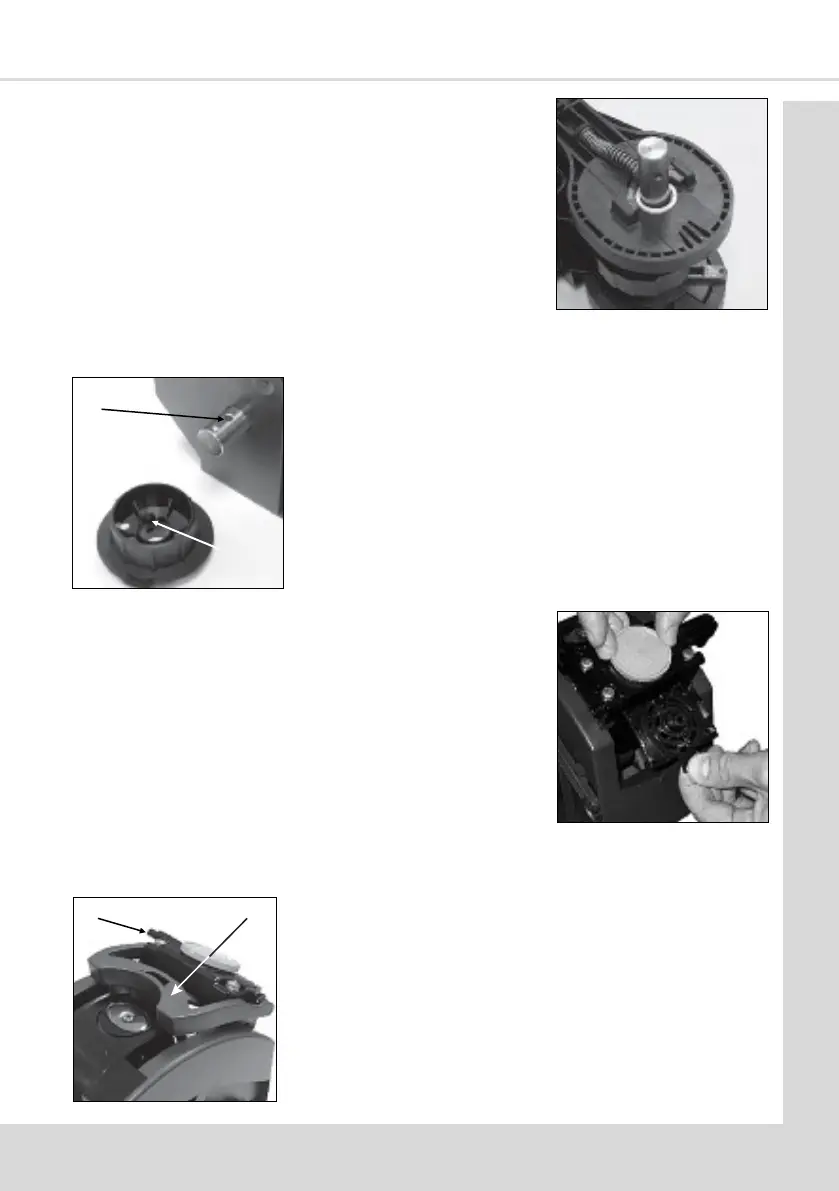

11. Ensure the plasc washer (a) if ed is placed correctly

over the input sha (long side) as shown.

Re-assemble the front and rear brewer panels to the

central piston chamber/swing arms assembly using the

three retaining screws/locknuts. Check and ensure that

the brewer release lever mechanism operates

correctly.

c

b

12. Re-t the brewer drive coupling to the input sha

ensuring that the raised ‘pip’ (b) lines up with its locang

dimple (c) on the input sha.

Ensure that the capve lock nut is retained in the plasc

drive coupling moulding. Ret the bolt to secure the

brewer drive coupling to the input sha.

e

d

Loading...

Loading...