Design Guide | VLT® AutomationDrive FC 360

7.3 Power Connections

NOTICE

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Non-UL

applications can use 75 °C (167 °F) and 90 °C (194 °F) copper conductors.

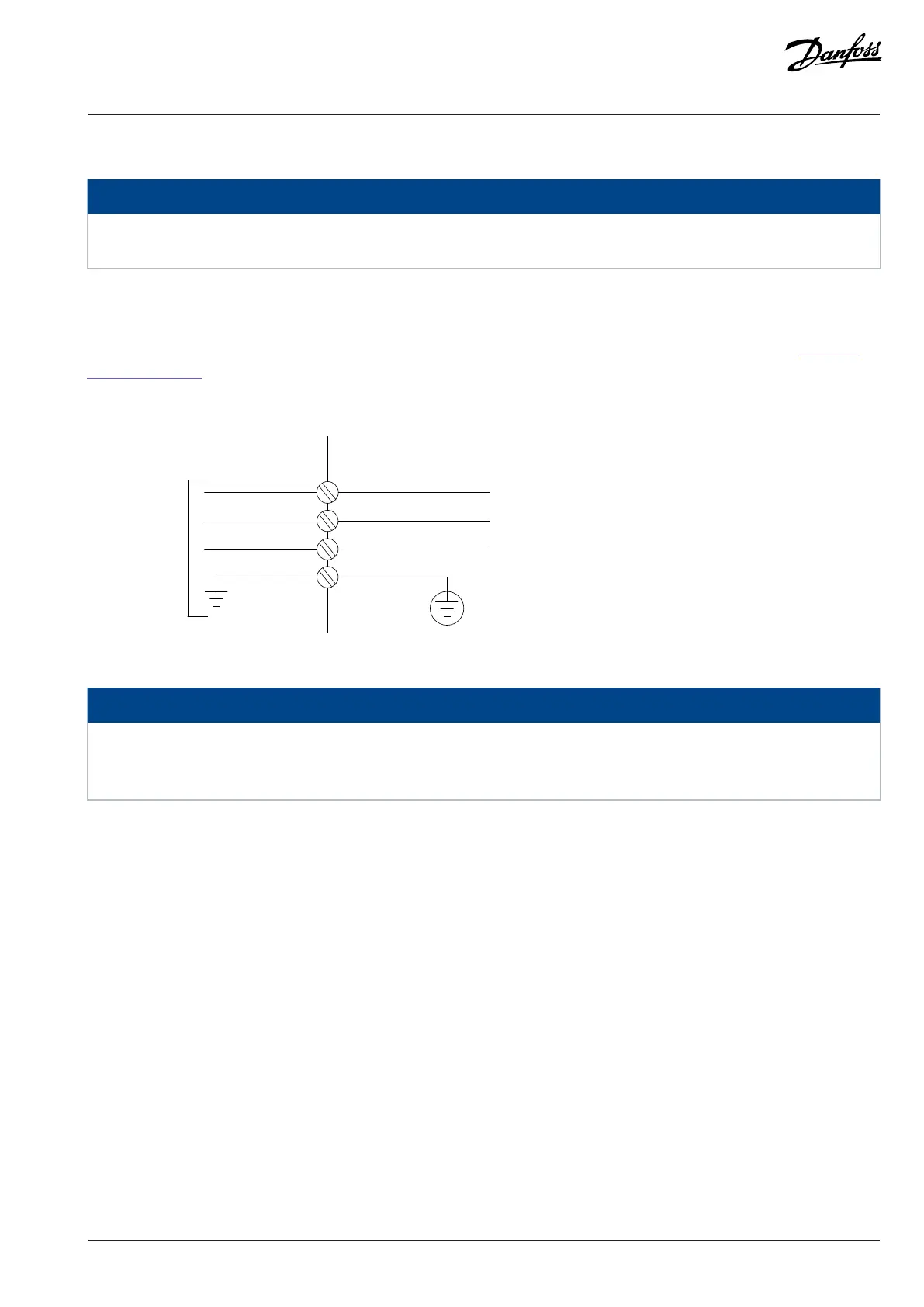

The power cable connections are located as shown in the following illustration. See chapter Specifications for correct dimensioning of

motor cable cross-section and length.

For protection of the drive, use the recommended fuses unless the unit has built-in fuses. Recommended fuses are listed in 7.5 Fuses

and Circuit Breakers. Ensure that proper fusing complies with local regulations.

The connection of mains is fitted to the mains switch if included.

e30ba026.11

91 (L1)

92 (L2)

93 (L3)

95 PE

Figure 21: Power Cable Connections

NOTICE

The motor cable must be shielded/armored. If an unshielded/unarmored cable is used, some EMC requirements are not complied

with. Use a shielded/armored motor cable to comply with EMC emission specifications. For more information, see chapter EMC-

compliant Installation.

Shielding of cables

Avoid installation with twisted shield ends (pigtails). They spoil the shielding effect at higher frequencies. If it is necessary to break the

shield to install a motor isolator or contactor, continue the shield at the lowest possible HF impedance.

Connect the motor cable shield to both the decoupling plate of the drive and the metal housing of the motor.

Make the shield connections with the largest possible surface area (cable clamp) by using the installation devices within the drive.

Cable length and cross-section

The drive has been EMC-tested with a given length of cable. Keep the motor cable as short as possible to reduce the noise level and

leakage currents.

Switching frequency

When drives are used together with sine-wave filters to reduce the acoustic noise from a motor, the switching frequency must be set

according to the instructions in parameter 14-01 Switching Frequency.

Danfoss A/S © 2024.01 AJ435824192086en-000101 / 130R1295 | 51

Loading...

Loading...