Design Guide | VLT® AutomationDrive FC 360

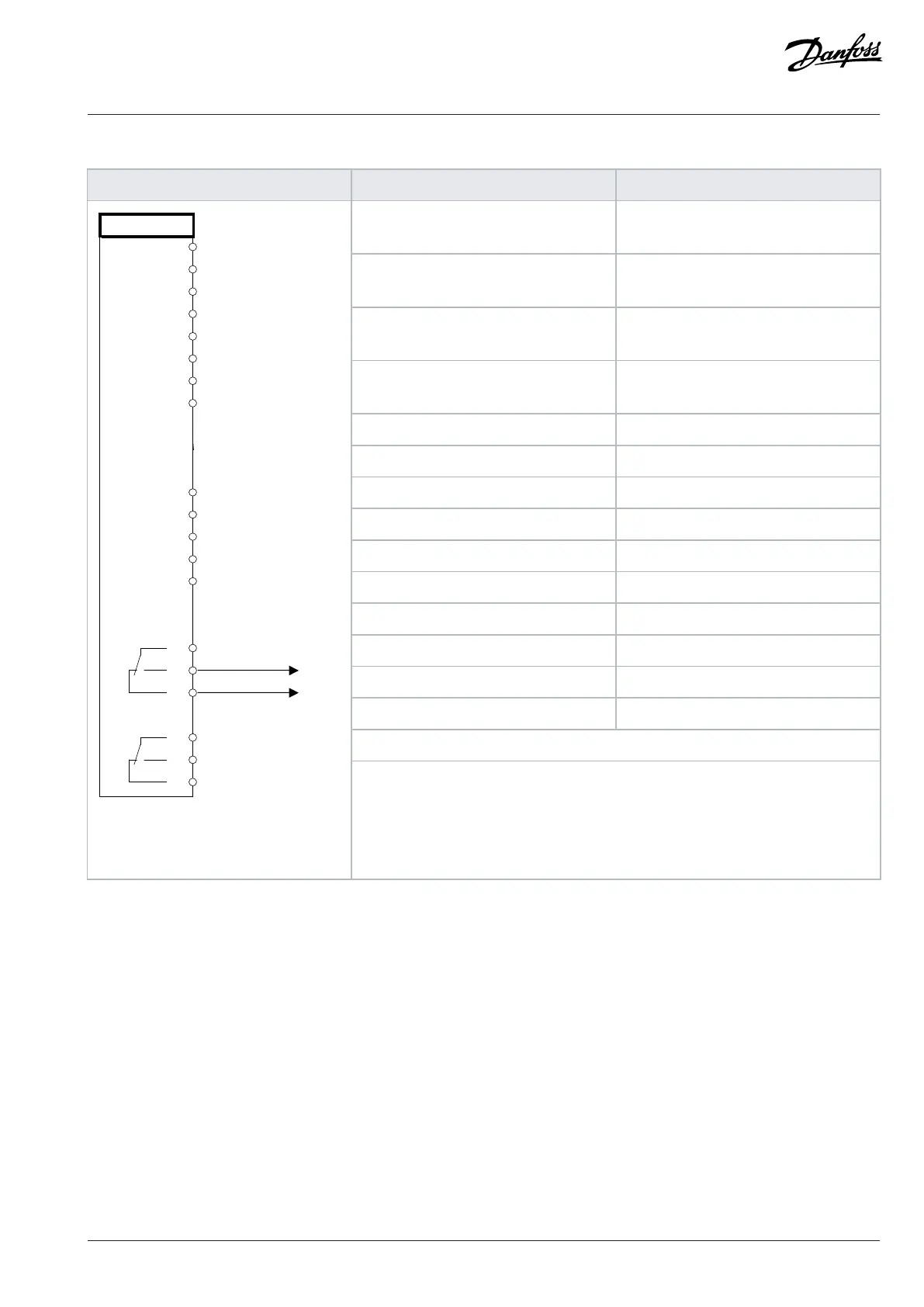

Table 74: Using SLC to Set a Relay

Parameter function Parameter setting

Parameter 4-30 Motor Feedback Loss

Function

[1] Warning

Parameter 4-31 Motor Feedback Speed

Error

100

Parameter 4-32 Motor Feedback Loss

Timeout

5 s

Parameter 7-00 Speed PID Feedback

Source

[2] MCB 102

Parameter 17-11 Resolution (PPR) *1024

Parameter 13-00 SL Controller Mode [1] On

Parameter 13-01 Start Event [19] Warning

Parameter 13-02 Stop Event [44] Reset key

Parameter 13-10 Comparator Operand [21] Warning no.

Parameter 13-11 Comparator Operator *[1]≈

Parameter 13-13 Comparator Value 90

Parameter 13-51 SL Controller Event [22] Comparator 0

Parameter 13-52 SL Controller Action [32] Set digital out A low

Parameter 5-40 Function Relay [80] SL digital output A

*=Default value

33

31

50

53

54

55

42

01

02

03

04

05

06

e30bd150.12

Notes/comments:If the limit in the feedback monitor is exceeded, warning 90 feedback

monitor is issued. The SLC monitors warning 90 feedback monitor. If warning 90 feed-

back monitor becomes true, relay 1 is triggered. External equipment could indicate that

service is required. If the feedback error goes below the limit again within 5 s, the drive

continues and the warning disappears. But relay 1 persists until [Off/Reset] is pressed.

10.7 Encoder Connection

The purpose of this guideline is to ease the setup of encoder connection to the drive. Before setting up the encoder, the basic settings for

a closed loop speed control system are shown.

Danfoss A/S © 2024.01 AJ435824192086en-000101 / 130R1295 | 127

Loading...

Loading...