English

8 Supplement Scio Four modules

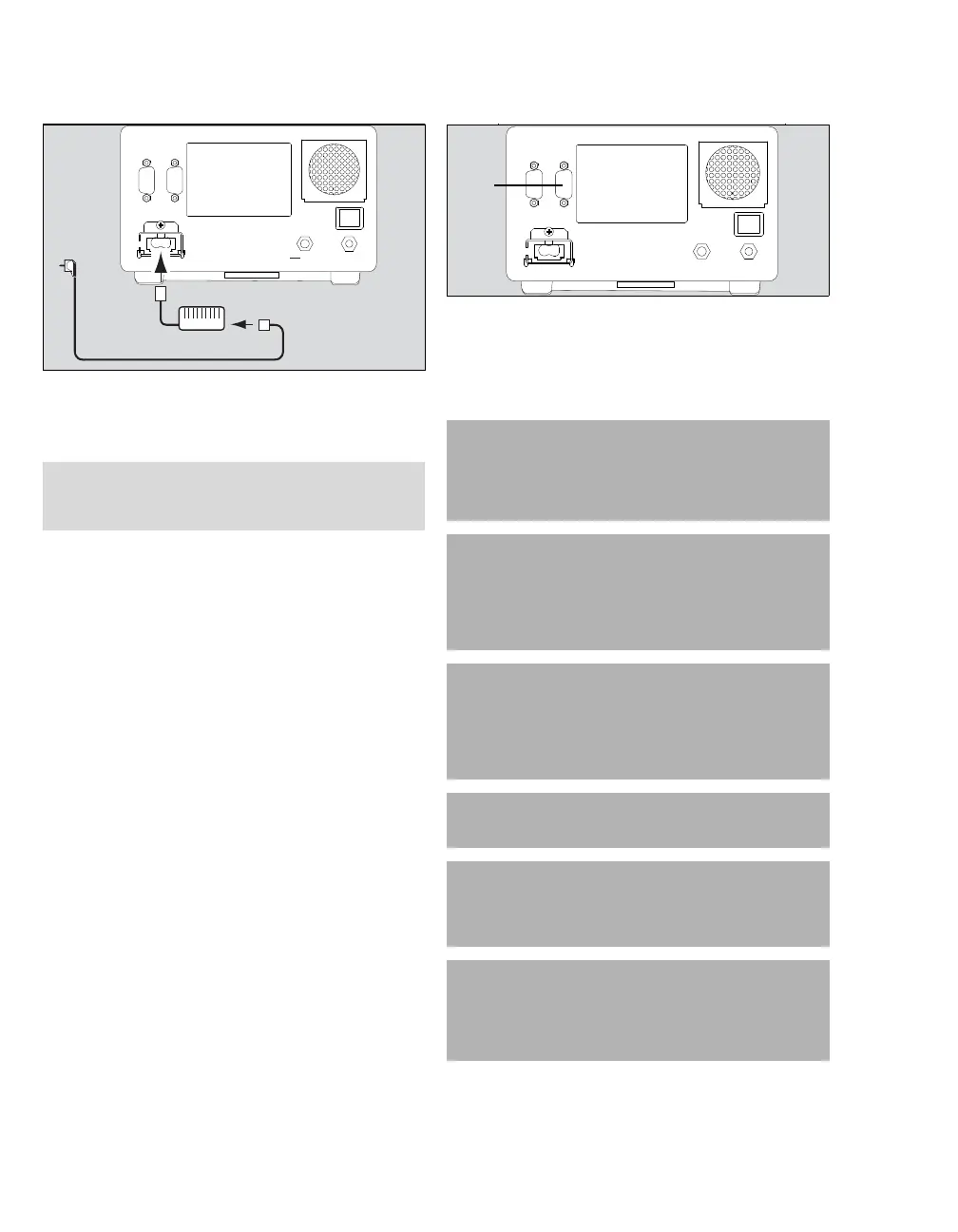

1 Connect the power supply with the "X16" connector to the rear

of the gas analyzer.

2 Connect the power cable to the rear of the power supply.

3 Plug the power cable into the mains power socket on the wall.

Establishing potential equalization

Differences in electrical potential between devices can be reduced

by potential equalization.

Potential equalization does not replace the protective ground con-

nection. During operation, the potential equalization connectors

must be readily accessible and the connection must be able to be

disconnected without the use of tools.

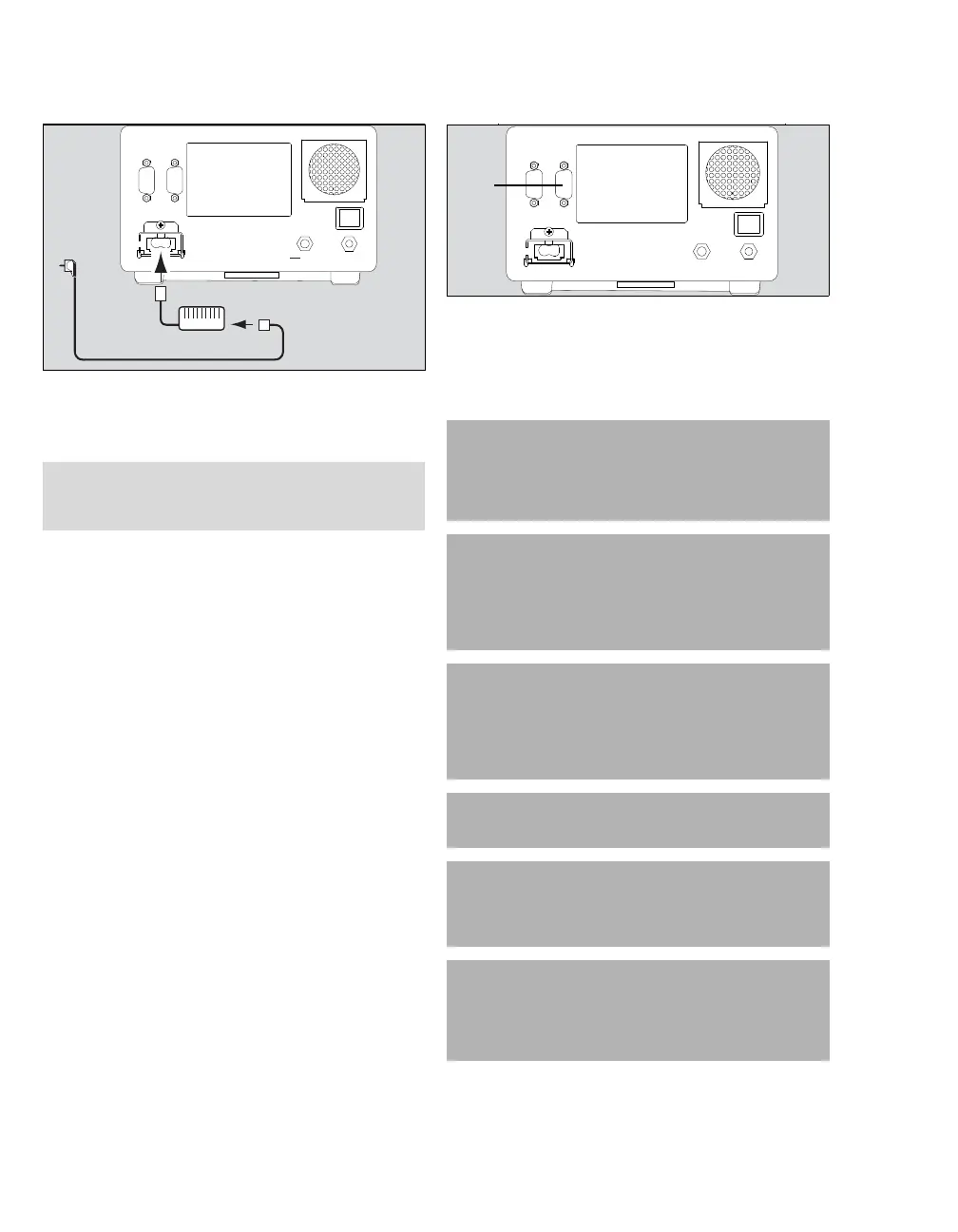

Connecting the potential equalization cable

1 Connect the potential equalization cable to the potential equal-

ization pin on the device (see page 6).

2 Connect the potential equalization cable to a potential equal-

ization connector of the hospital (e.g., wall, ceiling supply unit).

Connecting the gas analyzer to a patient monitor

The gas analyzer connects to the following patient monitors:

– Infinity Acute Care System

– Infinity Delta Series

– Infinity Gamma XL

– Infinity Gamma XXL

– Infinity Kappa XLT

(only Scio Four plus and Scio Four Oxi plus)

– Infinity Vista XL

– Vista 120

1 Connect and secure data interface cable with the "RS232C

X2" connector (A) on the back panel of the gas analyzer.

2 Connect the data interface cable with the connector at the

Infinity Docking Station or directly with the patient monitor.

Water trap

Empty or exchange the water trap in accordance with its instruc-

tions for use.

003

NOTE

Unplug the power cable from the mains power socket to discon-

nect the gas analyzer from power supply (e. g. for maintenance

or emergency reasons).

002

WARNING

Risk of infection

The liquid in the water trap may be contaminated and must

be handled and disposed of with care.

Dispose of the liquid in an adequate way and in compliance

with local regulations.

WARNING

Risk of infection

If the sample line remains connected while the water trap is

removed, contaminated liquid may escape from the water

trap.

Disconnect sample line before removing the water trap

from the medical device.

WARNING

Risk due to inaccurate gas measurement values and gas

measurement failure

Silicon can get into the measuring cuvette and influence the

gas measurement permanently.

Do not spray the O-rings of the water trap holder with sili-

con spray.

CAUTION

Risk of device failure

Do not operate the medical device without water trap.

CAUTION

Risk due to gas measurement failure

When the water trap is full, gas measurement can fail.

Check the level indicator in the water trap regularly and empty it

as necessary.

CAUTION

Risk due to gas measurement failure

Contaminants and damage of the water trap can influence gas

measurement.

Check and observe the replacement intervals of the water trap

and replace it as necessary.

Loading...

Loading...