Operating - Stopping

ICA134-3EN2.pdf2012-04-13

Operating - Stopping

Braking

Emergency braking

3

Fig. Instrument panel

3. Emergency stop

Braking is normally activated using the

forward/reverse lever. The hydrostatic transmission

brakes the roller when the lever is moved towards the

neutral position.

There is also a brake in the drum motor and rear axle

that acts as an emergency brake during operation.

For emergency braking, press the emergency stop

(3), hold the steering wheel firmly and be prepared

for a sudden stop. The brakes are applied and the

engine stops.

For emergency braking, press the emergency stop

(3), hold the steering wheel firmly and be prepared

for a sudden stop. The brakes are applied and the

engine stops.

After emergency braking, return the forward/reverse

lever to neutral position and pull out the emergency

stop (3). When the roller is fitted with an Interlock it is

necessary to sit down in the driver seat to restart the

engine.

Normal braking

1

4

2

3

6

31

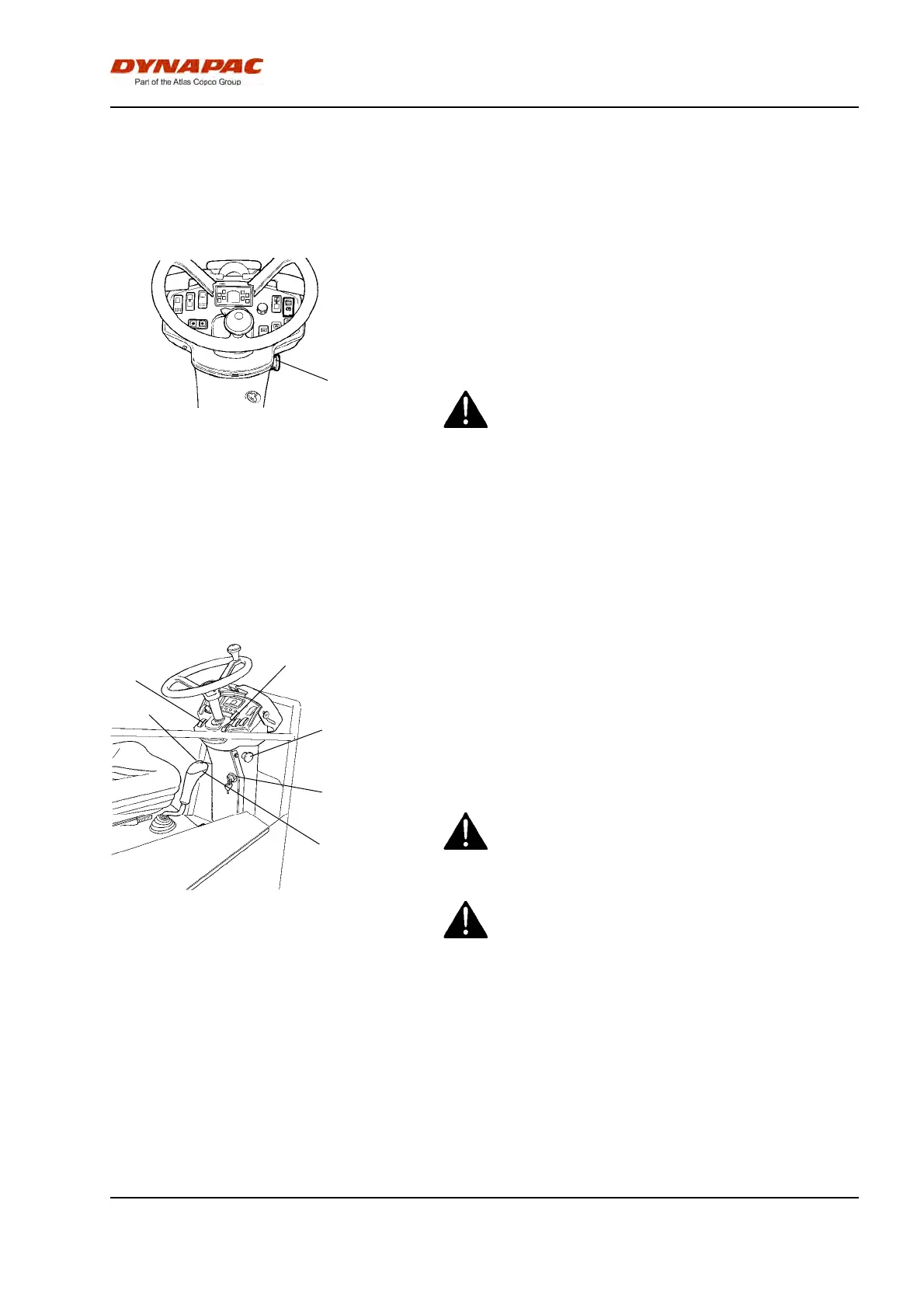

Fig. Instrument panel

1. Key

2. Speed control

3. Emergency stop

4. Vibration On/Off

6. Forward/Reverse level

31. Parkering brake switch

Press the switch (4) to switch off the vibration.

Move the forward/reverse lever (6) to the neutral

position to stop the roller.

Set the speed control (2) to idling position: Low.

Set the parkering brake switch (31) in the On position.

Always use the parking brake (31) when the

machine is stationary on a sloping surface.

Always use the parking brake (31) when the

machine is stationary on a sloping surface.

When starting and driving a machine that is cold,

remember that the hydraulic fluid is also cold and

that braking distances can be longer than normal

until the machine reaches the working temperature.

When starting and driving a machine that is cold,

remember that the hydraulic fluid is also cold and

that braking distances can be longer than normal

until the machine reaches the working temperature.

47

Loading...

Loading...