149

support@edgeovens.com

Technical Support: +1 (724) 628 3050

SERVICE

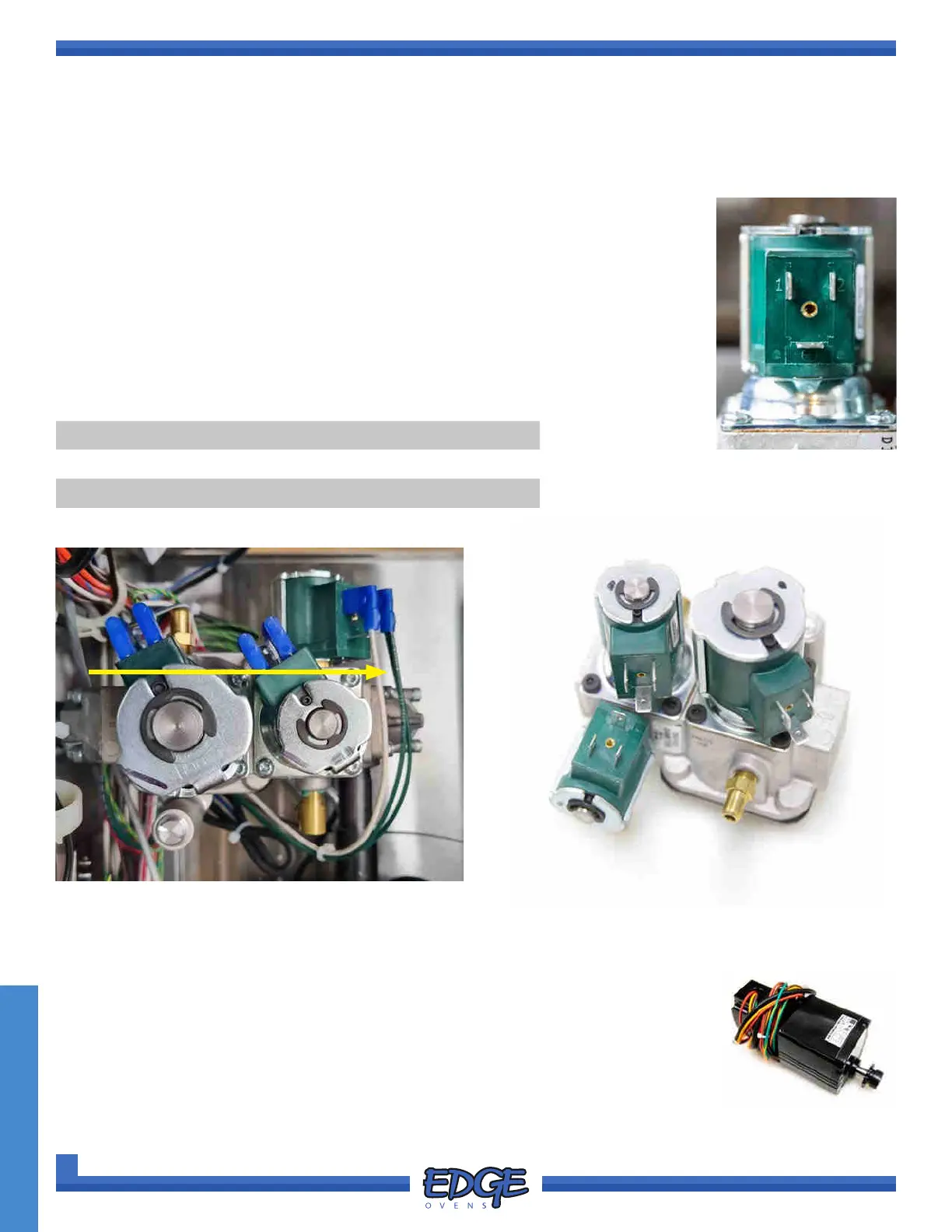

To test, measure the resistance between post 1 and 2 on each coil (Figure 4-45).

These coils do naturally become HOT to the touch during normal operation.

The BASO ignition module performs a test on the PV (Pilot Valve) and the MV (Bypass/

High Flame Valve) connections at start up. A 3 x RED FLASH ignition module (IM)

fault indicates a Pilot Valve connection or coil failure; whereas, a 4 x RED FLASH fault

indicates a Bypass coil failure.

If a coil measures correctly and voltage is present to the coil but the valve is not opening,

ensure the supply pressure to the valve is not greater than 37mbar/14.8inW.C. before

condemning the valve.

MAIN VALVE COILS

PART FAILURE VERIFICATION

CONTROLS AND ASSEMBLIES (CONTINUED)

1 2

3

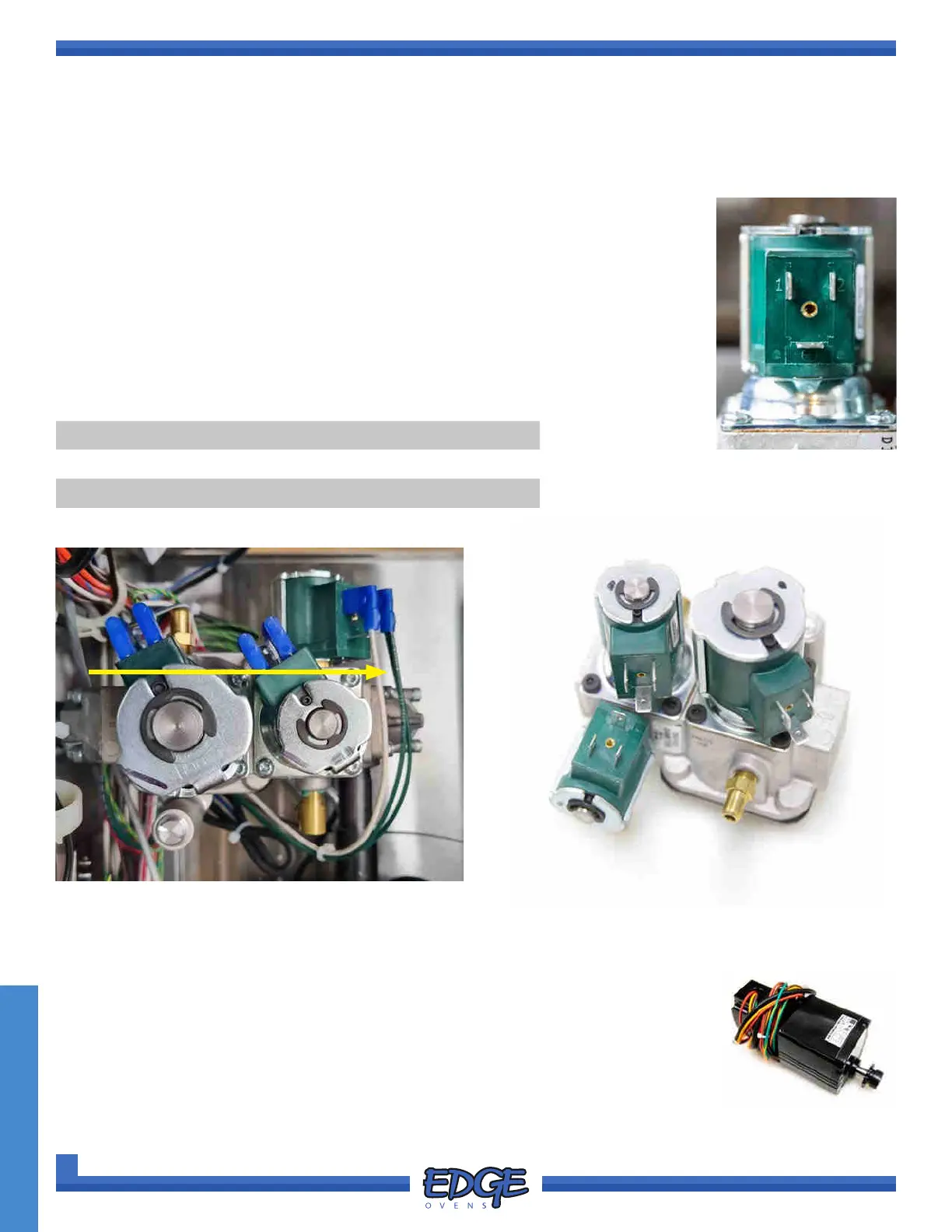

FLOW DIRECTION

FIGURE 4-46

The conveyor motor is powered and monitored by the control system (MC1 and MC2).

This is a 3 Phase, 24VDC motor with Hall Effect feedback. Do not attempt to power

the motor by other means.

1. If the motor is bound, this may indicate a lubrication problem from staging (new

installs or prolonged idle periods more than 30 days). A slight manual rotation of

the sprocket will resolve this.

2. Use the ‘EXPORT’ feature to obtain a logle from the oven to thoroughly diagnose

conveyor motor problems which fall outside of the ‘idle’ condition mentioned.

CONVEYOR MOTOR

1

2

3

FIGURE 4-45

COIL APPLICATION COIL SIZE RESISTANCE

1. Pilot Valve 15VA COIL 6M Ω ~ 8.5M Ω

2. Main (High Flame) Valve 10.5VA COIL 5M Ω ~ 6M Ω

3. Bypass Valve 10.5VA COIL 5M Ω ~ 6M Ω

Loading...

Loading...