50

support@edgeovens.com Technical Support: +1 (724) 628 3050

INSTALLATION

MANIFOLD PRESSURE ADJUSTMENT

The MANIFOLD PRESSURE is to be adjusted to the region specications and gas type

provided earlier in this manual.

NOTICE

Damaged gas valves as a result of over adjustment are NOT covered under warranty.

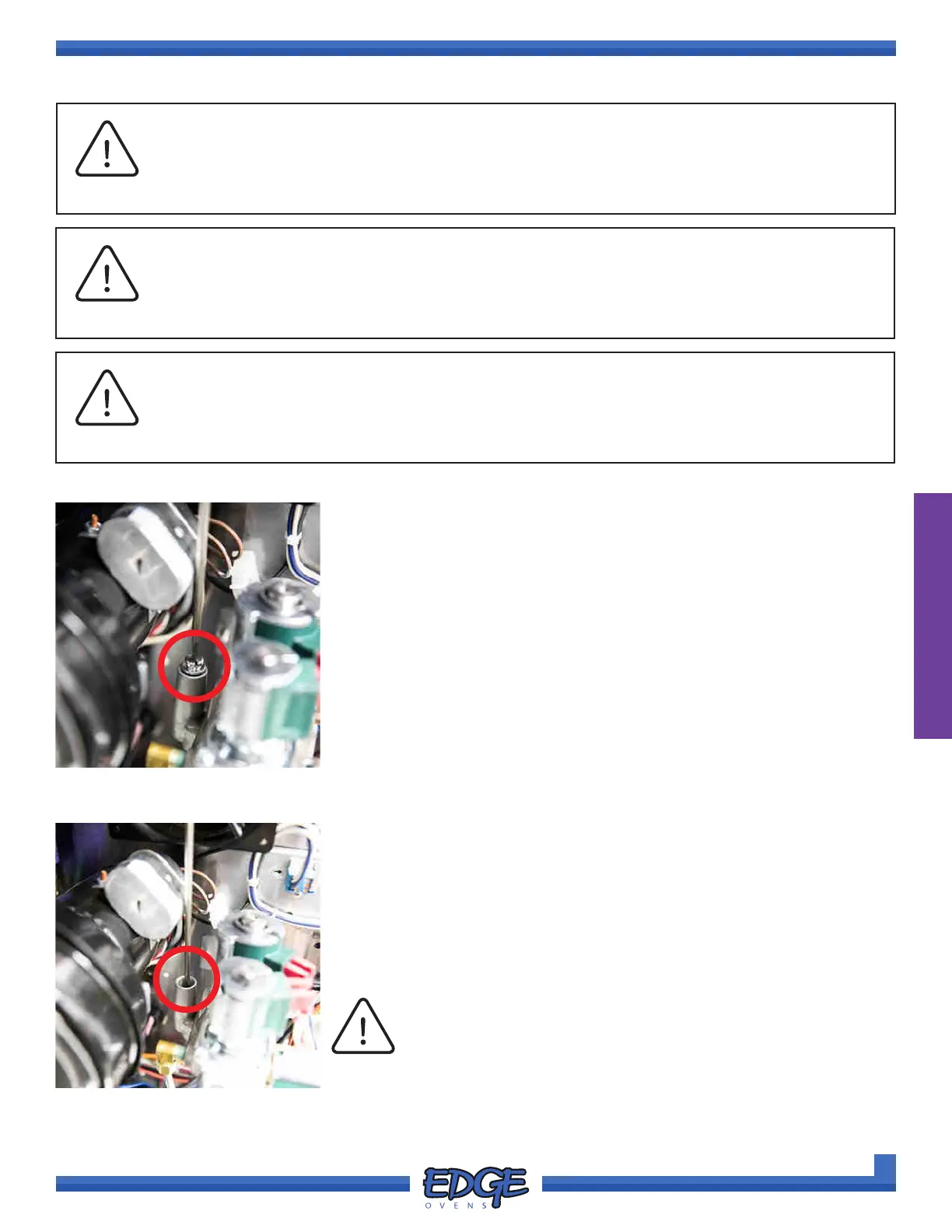

1. Remove the cap from the regulator spring (4) (Figure 2-121) and

connect your manometer to the MANIFOLD PRESSURE TAP. (Figure

2-116)

2. Turn the oven ON (Figure 2-117) and make a note of the pressure on

the manometer within 15 seconds of the MAIN blower motor spinning

up (Figure 2-118). This is the zero from which adjustments will be

made.

3. When the oven lights, make a note of the new pressure reading

(Figure 2-119). Before adjusting the manifold pressure subtract your

initial measurement, outlined in step 3, from the current pressure

reading. This will give you your true manifold pressure measurement.

FOR EXAMPLE:

Step 2 pressure: (-)0.25 inWC

Step 3 pressure: (+)4.00 inWC

(Step 3 Pressure) - (Step 2 Pressure) = True Manifold Pressure

(+)4.00 - (-)0.25 = 4.25 inWC

In this example a Natural Gas oven requires a manifold pressure

setting of 4.5 inWC, so based on the calculation above an increase in

pressure of 0.25 inWC is required.

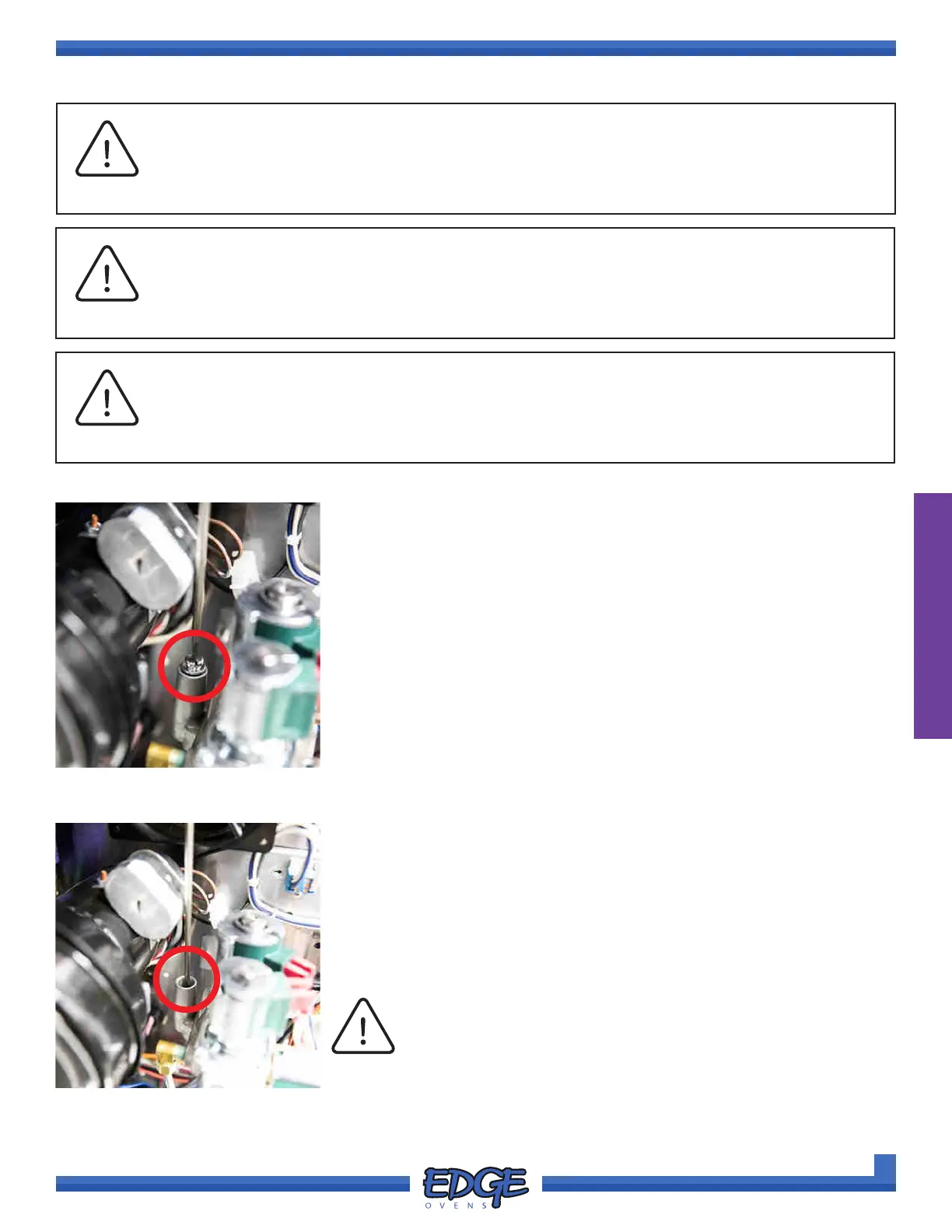

4. Using a standard slotted screwdriver, rotate the regulator adjustment

nut clockwise (CW) to increase the pressure and counter-clockwise

(CCW) to decrease the pressure. (Figure 2-122)

NOTICE

Ensure the oven is cold before undertaking MANIFOLD PRESSURE adjustment. Before

commencing adjustment, oven temperature should be set to 500F/260C.

IMPORTANT

FIGURE 2-121

FIGURE 2-122

Apply a light downward pressure to the regulator

adjustment nut. The plastic adjustment nut can be damaged

by excessive force.

NOTICE

5. When adjustment is complete, turn off the oven, install the

REGULATOR SPRING CAP, disconnect your manometer and

tighten manifold gas tap screw.

Loading...

Loading...