47

support@edgeovens.com

Technical Support: +1 (724) 628 3050

INSTALLATION

FINAL CONNECTIONS

GAS

Always check for leaks after making any gas supply piping connections or performing

any service on the oven. Leak testing is required during installation.

WARNING

VALVE SPECIFICATIONS

MAXIMUM INLET PRESSURE: 37 mbar / 14.8 inWC

HEATING CAPACITY: 58.6kW / 200,000 BTU/hr

PRESSURE DROP ACROSS VALVE: 3.7 mbar / 1.5 inWC

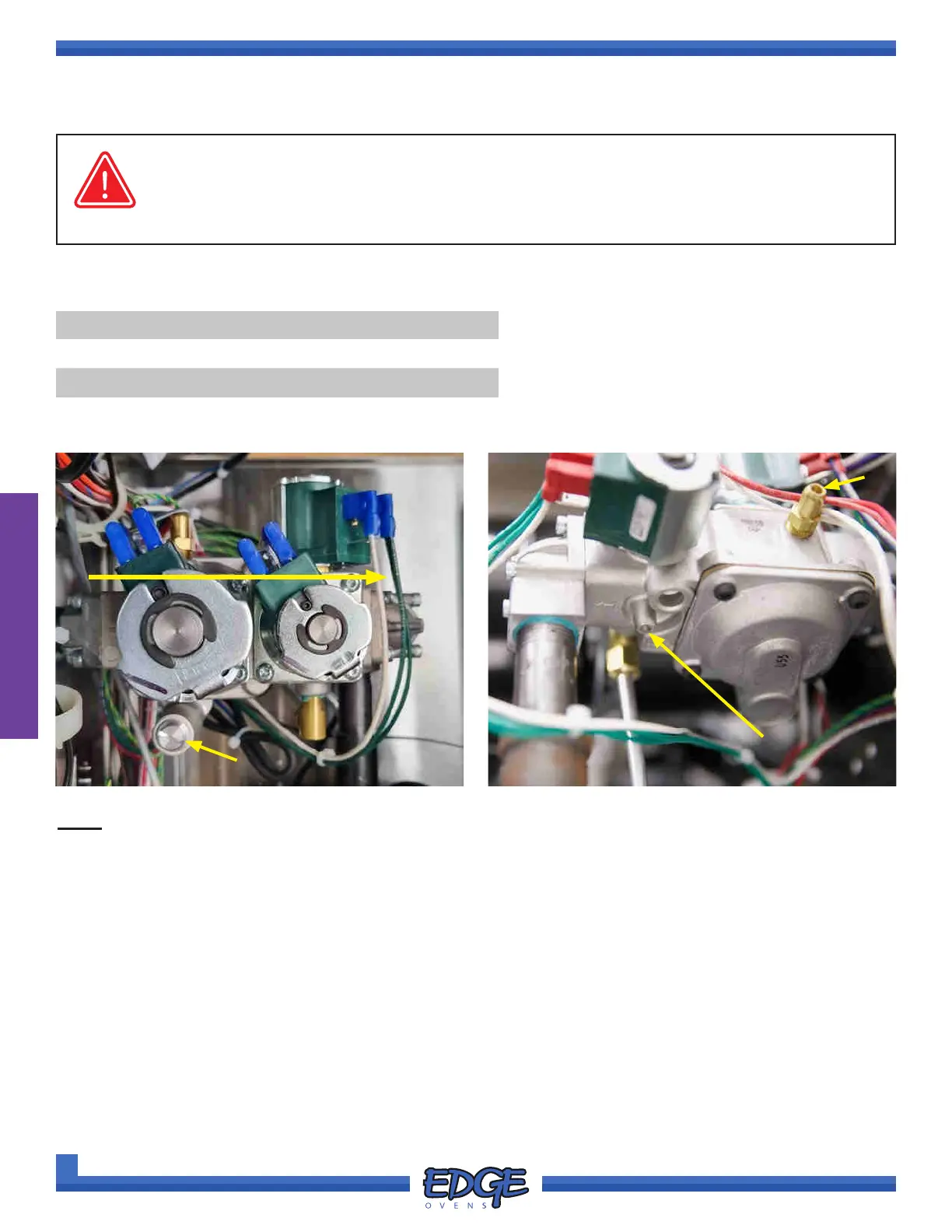

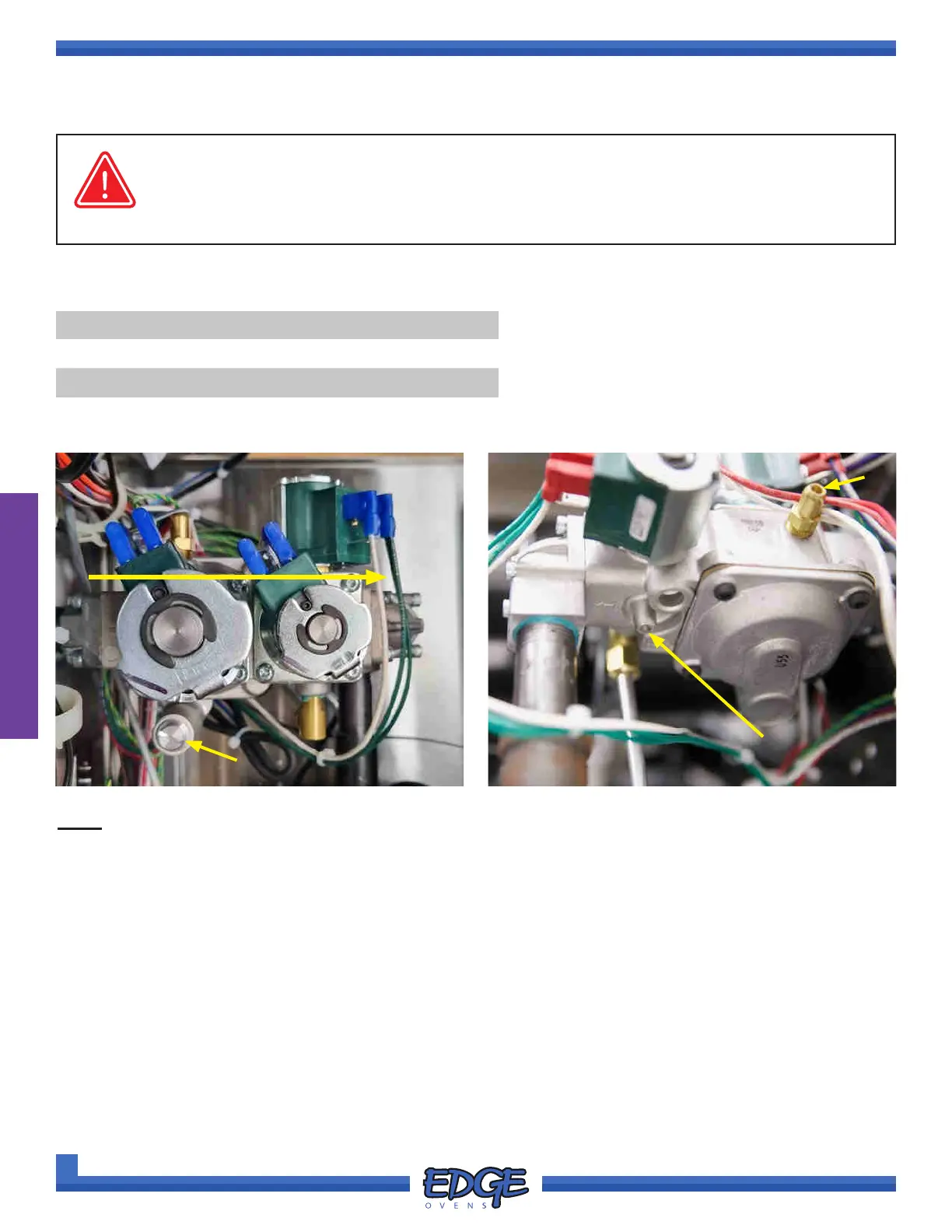

KEY

1. PILOT VALVE

2. MAIN VALVE

3. BYPASS VALVE

4. REGULATOR SPRING

5. MANIFOLD PRESSURE TAP

6. INLET PRESSURE TAP

1 2

3

FLOW DIRECTION

Adjustment of the manifold pressure, via the valve regulator spring, is

generally not required. Manifold pressure is factory adjusted.

The correct setting for the manifold is stated in the section ‘OVEN GAS

SPECIFICATIONS’, in the ‘SPECIFICATION’ section of this manual, or

can be located on the data plate located on the oven control cabinet side

and on the secondary plate located on the inside of the control cabinet.

5

6

4

The INLET PRESSURE TAP (6) allows measurement of the supply or

“curb” pressure in to the gas valve.

The MANIFOLD PRESSURE TAP (5) allows measurement of the manifold

pressure out of the of the gas valve.

The REGULATOR SPRING (4) provides the means to adjust the manifold

pressure.

FIGURE 2-108 FIGURE 2-109

Loading...

Loading...