29

support@edgeovens.com

Technical Support: +1 (724) 628 3050

INSTALLATION

FINGER PANEL ASSEMBLIES EXPLAINED

OVEN ASSEMBLY

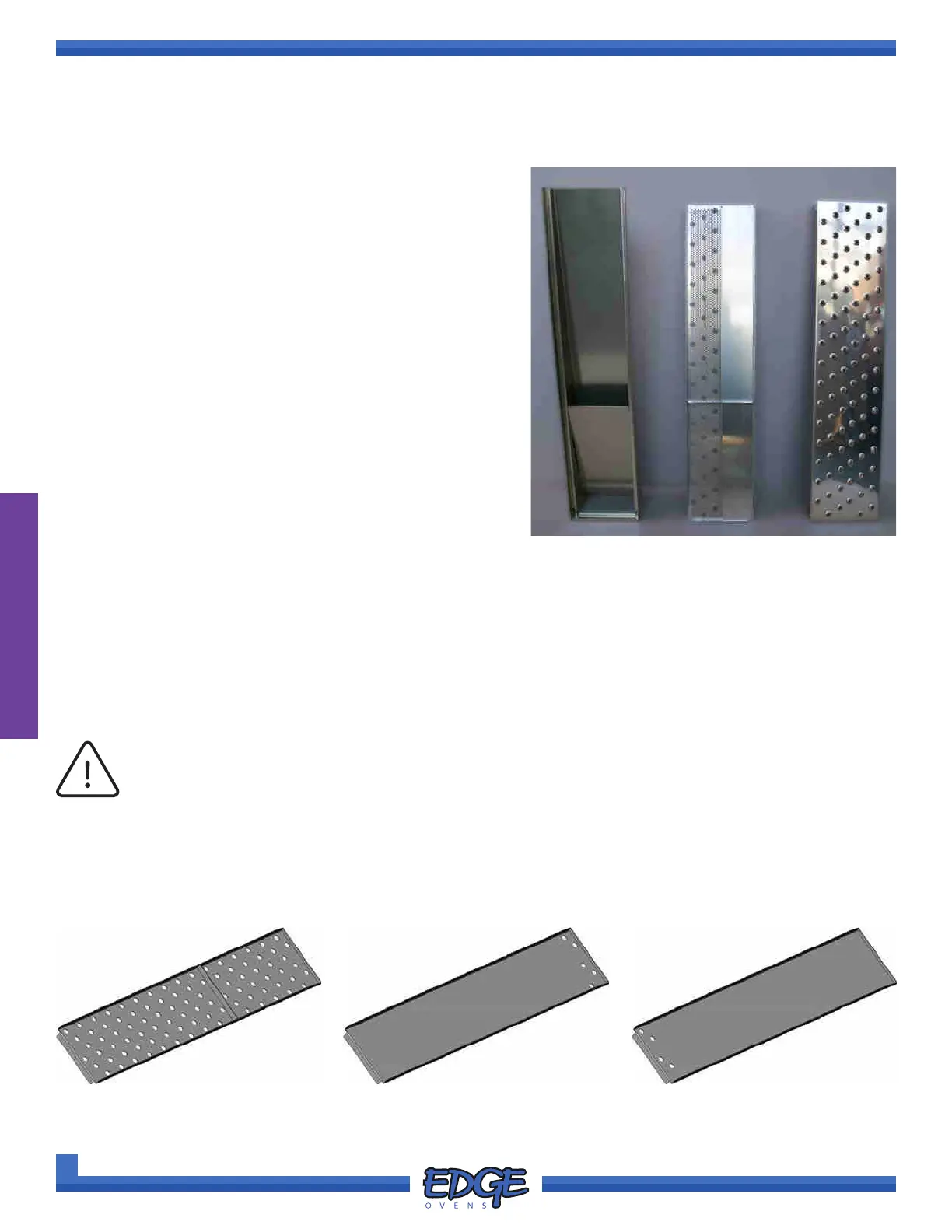

All EDGE ovens are shipped with eight (8), twelve (12)

or fourteen (14) nger assemblies per oven. Each nger

assembly consists of three (3) parts:

A) Finger Housing

B) Columnating Panel

C) Finger Cover

The nger assembly pattern of the oven determines the

baking characteristics. Once the nger pattern is known,

record it on the decal on the side of the control cabinet for

future reference.

FINGER COVER

Finger covers are essential to the creation of impinged

air. They, in addition to the columnating panels, create the

pressurized columns of air used in the impingement cooking

process. Traditionally all nger covers are fully open with

maximum number of hole openings (as shown Figure 1-C),

for some chain accounts a nger cover with a reduced

number holes can be used and may also have to be veried

when conrming nger conguration.

A B C

FIGURE 2-59

COLUMNATING PANELS

Columnating panels are used within the oven nger housing and control the volume of air allowed to pass

through the nger cover. Additional columnating panels may also be provided with the oven. The majority of

ovens are built with a universal pattern pre-installed. Additional panels are provided to alter the oven baking

characteristics, to best match the product being baked. For further information, please consult you EDGE oven

sales representative.

Failure to install the nger panel assemblies in the ovens in the order they were removed or

as per the prescribed conguration could negatively affect the bake performance.

NOTICE

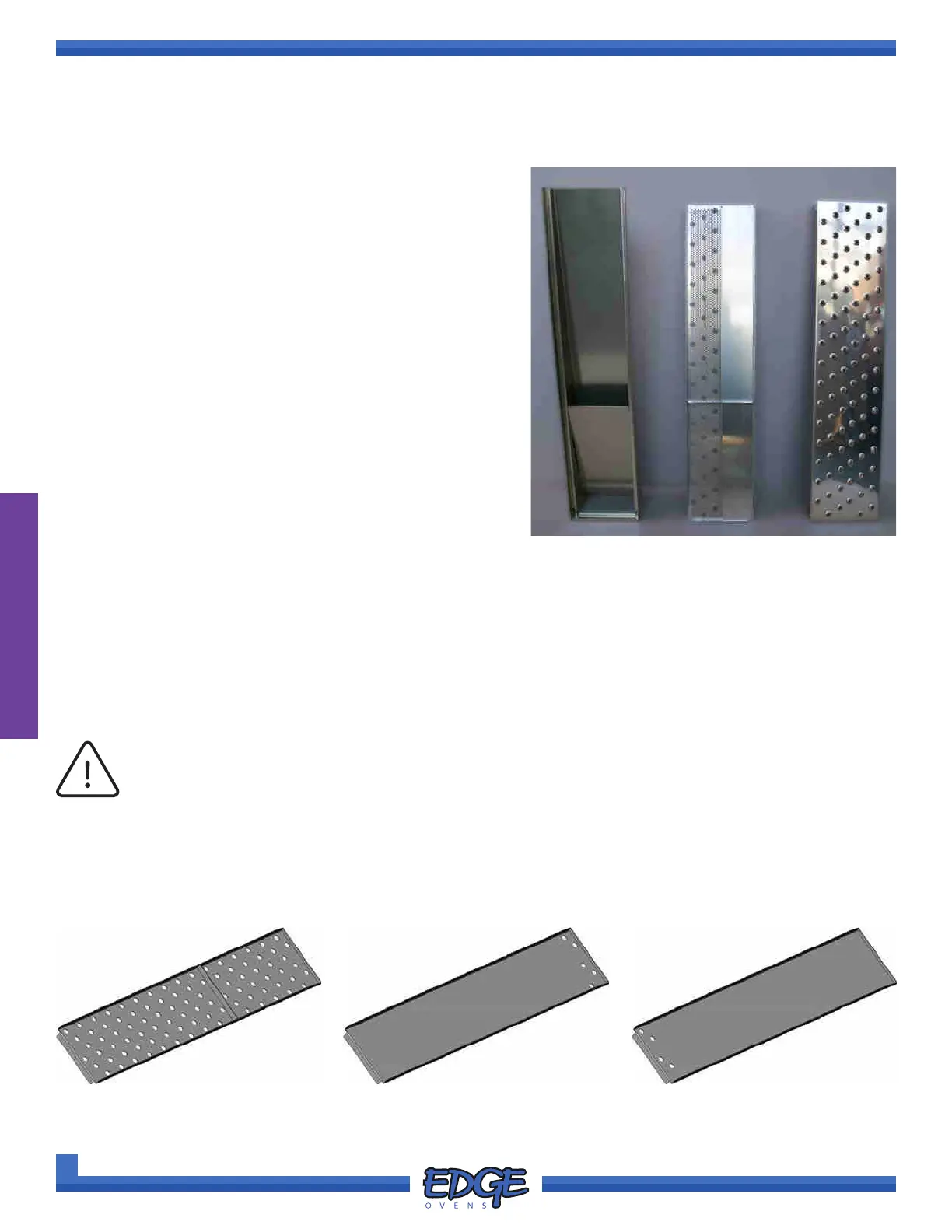

COLUMNATING PANEL OPTIONS

#10 FULL OPEN #20 BACK EDGE OPEN #25 FRONT EDGE OPEN

Provides 100% impingement air

across the entire panel.

Provides a small increase to the

back-edge impingement air and

radiant only heating elsewhere.

Provides a small increase to the

front-edge impingement air and

radiant only heating elsewhere.

Please note that for visualization purposes that the columnating panels are shown facing upwards, installation of

these panel in the TOP nger assemblies will require the panels to be installed DOWNWARDS facing.

Loading...

Loading...