5-4 Diagnostics/Troubleshooting

P/N 0013-1027-005 Rev A

On some machines you may want the IQ to continue running even after some faults occur. This

is accomplished by setting Disable on Fault to Partial. In this case, the following faults are

disabled: Iavg fault, Motor Overtemperature, Soft Forward Limit, and Soft Reverse Limit. All

faults will cause the Error output to turn ON (if enabled). However, if Disable on Fault is set to

Partial, and a fault listed above occurs, the IQ will remain enabled and execute motion programs

normally. The Error output in this case serves as an alarm, and a programmable logic controller

(PLC) or other controller can then gracefully shut down the machine without damaging the

tooling or work piece. This setting is made in the Parameter menu, System dialog box of

IQ Master, or with the FLTDIS Host Language Command. Refer to the IQ Master Instruction

Manual, Chapter 2, Parameter menu > System or to the IQ Master Instruction Manual, Chapter 6

for more information.

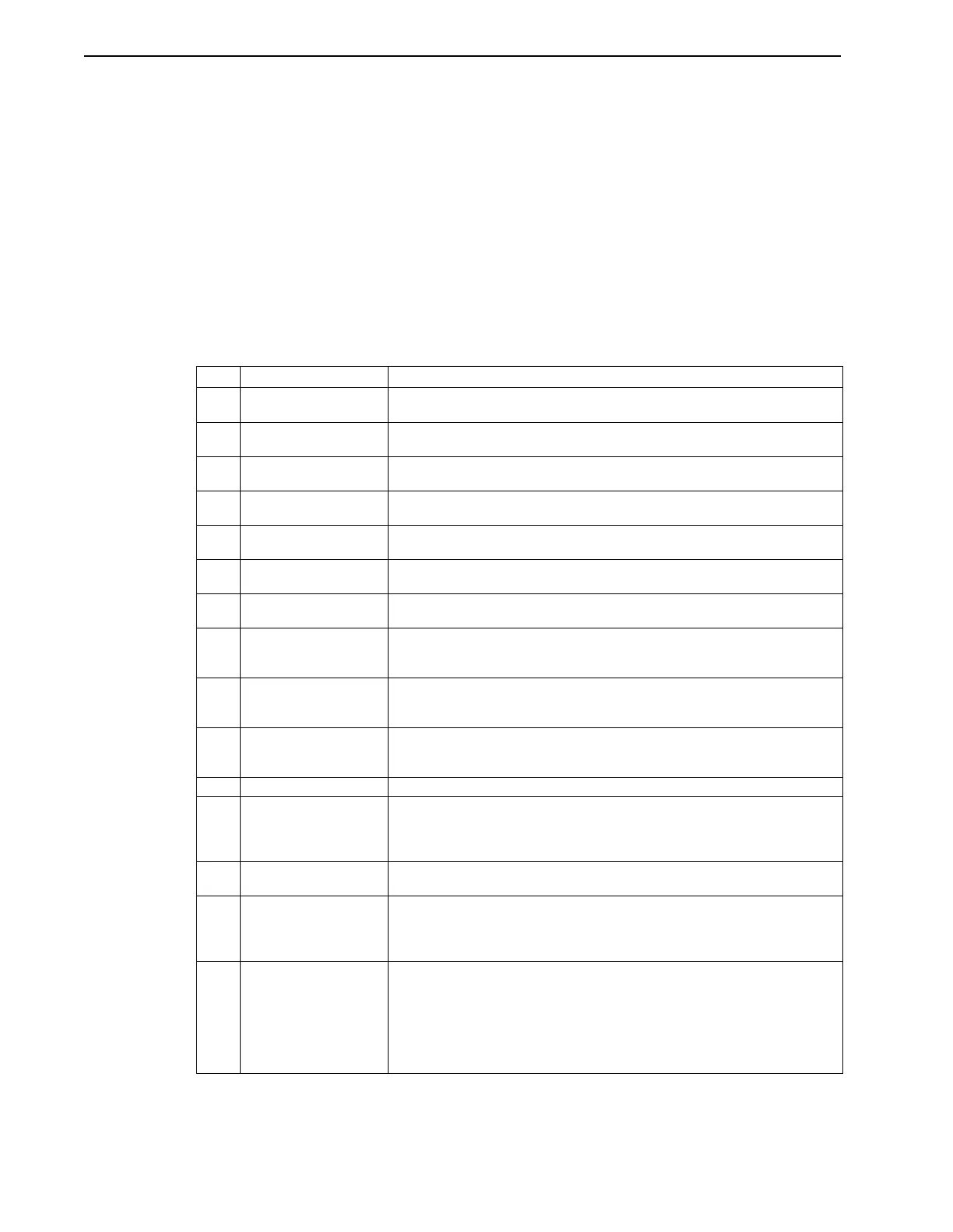

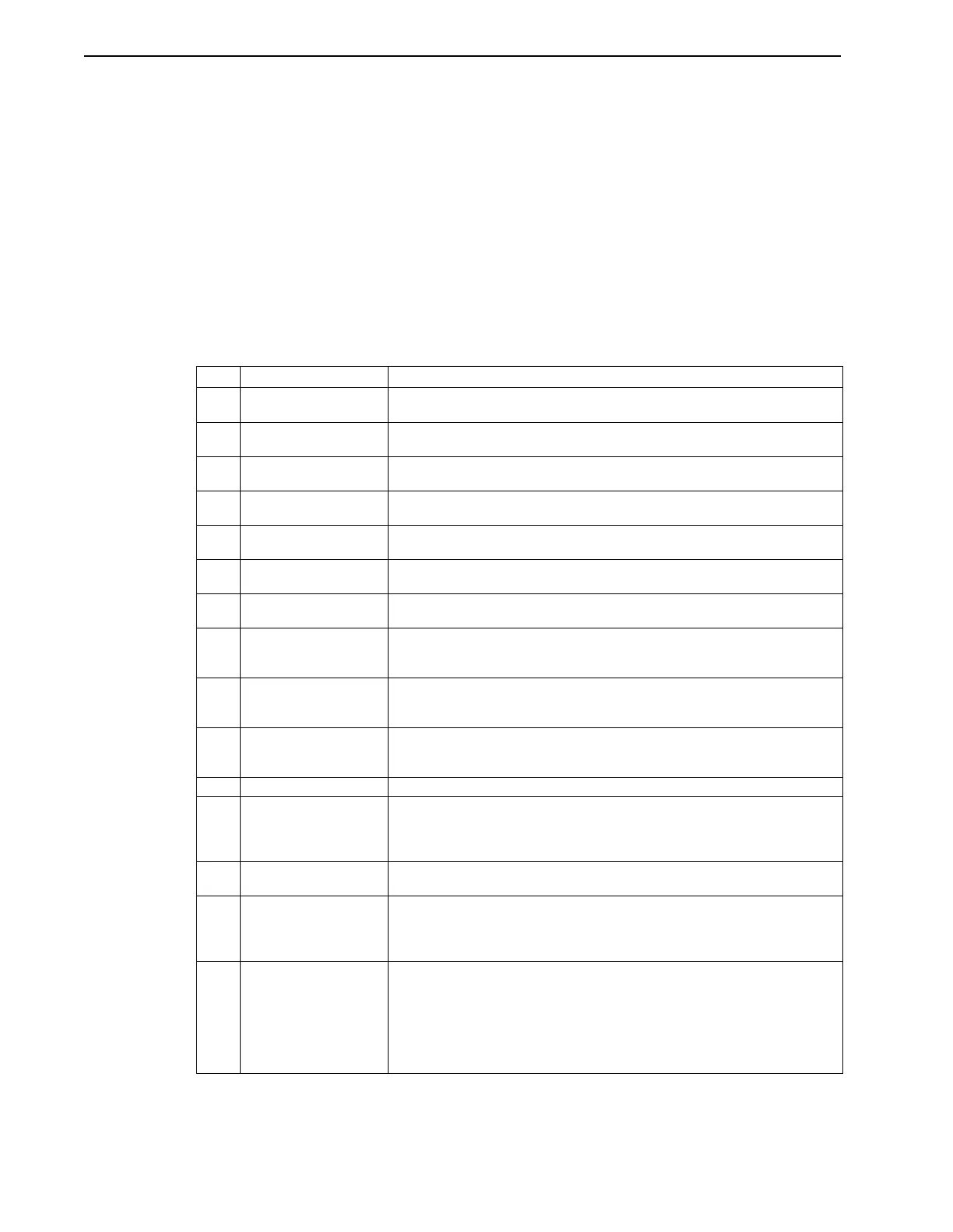

Table 5.3 lists the faults that activate the Error output. The number preceding the fault is the

error number.

TABLE 5.3 Error Messages

No. Error Message Description

3 2ms Reentrancy Fault The system did not finish the required calculations in the previous 2ms position

loop update in time for the next position loop update.

4 Math Overflow A math overflow occurred (a calculation exceeded the internal system limit).

Check the values of the variables used in the program.

5 Divide by Zero A division by zero calculation was attempted. Check the values of the variables

used in the program.

6 LOOP variable range A variable used as the count for a LOOP statement was out of range. The valid

range of a LOOP count is 0 to 65535.

8 PRECISION Out of

Range

Decimal point precision is not within the range of 0 to 4.

9 BCD Input Range A number larger than 9 was read in as a BCD number in a BCD statement in a

program. Check the inputs that are being used for the BCD input.

12 LOOP Count Out of

Range

Loop constant value is not within the range of 0 to 65535.

13 Profile Calculation The move cannot be made based on the parameters for the move: distance,

velocity, acceleration, or time. Possible causes are variable values used for the

move parameters that result in an acceleration or time of 0.

16 Invalid Opcode The PDM tried to execute a program opcode that was not valid (programs are

compiled into opcodes that the PDM executes). Compile the program again to

make sure it compiles correctly.

17 Home Not Defined Home has not been defined when trying to execute a MOVP (absolute) move.

Run the Home program or Define Home and execute the MOVP command

again.

19 Delay Out of Range Time value for a Delay statement is greater than 65,535 seconds.

20

21

22

23

KP Out of Range

KFF Out of Range

KI Out of Range

KPZ Out of Range

The parameter listed has exceeded the internal system limit. The limit is deter-

mined at run time based on the Scale parameter. Check the gain values under

the Parameter menu.

24 Gear Out Of Range The calculated value for the gear ratio denominator is greater than 32,767.

Check that the value is correct.

30

31

32

Calculations:

S-Curve

Accel

Velocity

The calculation listed has exceeded the internal system limit. The limit is deter-

mined at run time based on the Scale parameter. Check the velocity and acceler-

ation values under the Parameter menu.

33 Iavg Fault The average current output of the PDM exceeded safe levels for the motor or

PDM. Check for correct connection of the motor encoder to the PDM or of the

motor leads to the PDM. Other possible causes are motor stall or end of travel

condition, excessive duty cycle, or no DC bus voltage. This can also occur if the

drive is enabled and there is power supplied to the L1 and L2/N AC AUX inputs,

but not to the L1 and L2/N AC main inputs (this provides logic voltage, but no DC

bus voltage).

Loading...

Loading...