SC-F2000 Revision C

ADJUSTMENT Overview 194

Confidential

[Blue]: Button or menu name on the program screen / [Black]: Button or menu name on the operation panel of the printer

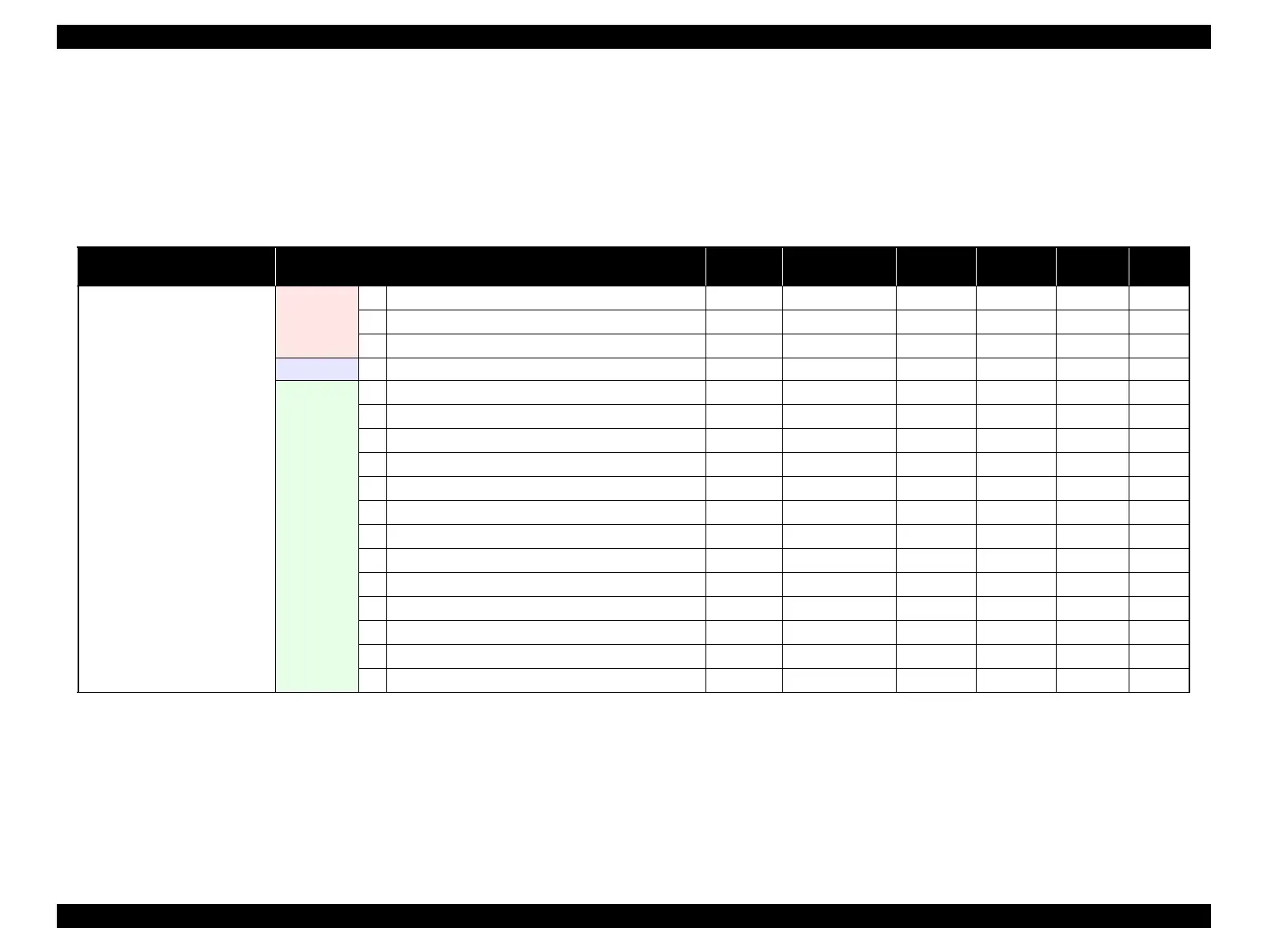

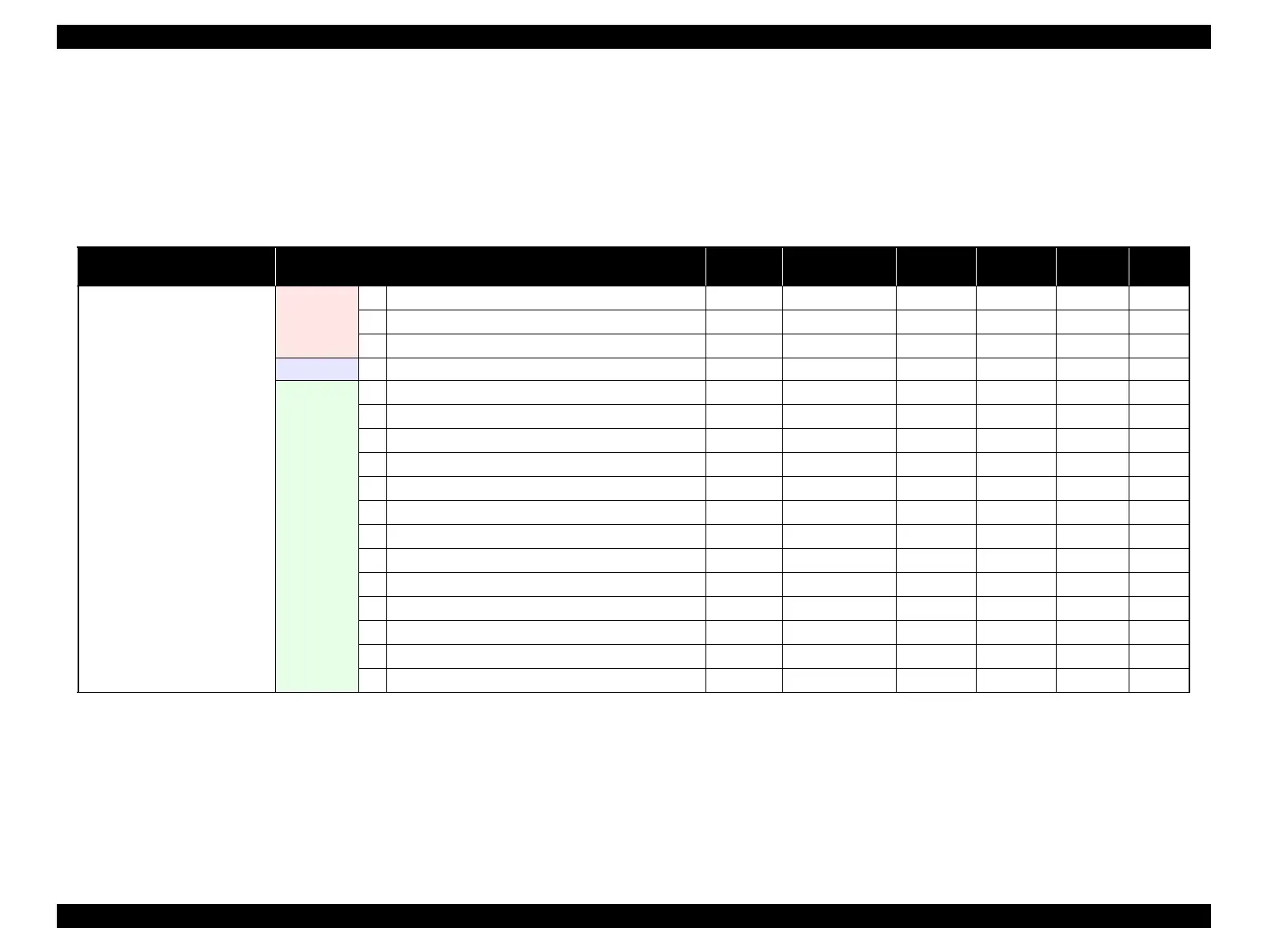

4.1.2 Adjustment Items and the Order by Repaired Part

The following table shows the required adjustments by repaired or replaced part and the order in which the adjustments must be performed.

NOTE 1: The adjustments required for the Main Board differs depending on whether the NVRAM on the old board can be backed up or not.

2: When the firmware update is required, first check the version of firmware currently installed on the printer, then update the firmware if necessary.

3: PGPP: Premium Glossy Photo Paper (250)

Table 4-1. Adjustment Items and the Order by Repaired Part

Replaced or Repaired

(Reattached) Part/Unit

Required Operations

Service

Program

Jig Media Replaced Reattached Page

Print Head

Before

replacement

1 PG Check

√ Thickness gauge

√

√ p. 246

2 Turn the power on in Serviceman mode. ---

√

√

3 Move the CR UNIT to the full side. (manually) ---

√

√ p. 69

Replacement 4 Replace with a new one. --- √√p. 109

After

replacement

5 Clamp position adjustment ---

√

√ p. 233

6 Turn the power on in Serviceman mode.

---

√

---

7 Reset the Print Head counter.

√√

--- p. 221

8 Head ID Input

√√

--- p. 235

9 PG Check/PG Adjustment √ Thickness gauge

√√

p. 246

10 Turn the power on in normal mode. ---

√√

11 CL3

√√

√ p. 238

12 Nozzle Check & Cleaning

√

PGPP

√

√ p. 237

13 Head inclination adjustment

√

PGPP

√√

p. 239

14 Head slant adjustment

√

PGPP

√√

p. 243

15 PG Check/PG Adjustment

√

Thickness gauge

√√

p. 246

16 Manual Uni-d adjustment

√

PGPP

√√

p. 227

17 Manual Bi-d adjustment

√

PGPP

√

√ p. 229

Loading...

Loading...