EPSON Stylus Photo R1900/R2880/R2000/R2000s/SC-P400 Series Revision I

Adjustment Adjustment 147

8. Press the [MEASURE] button. (“----” is displayed on the LCD screen.)

9. Put the tip of the tweezers on the Drive Belt, and flip it downward in that position.

The “----” displayed on the LCD will become wave pattern during the

measurement. When it has finished, the measurement result will be displayed by

“N” (Newton) after the beep. This jig can pick up and measure sounds accurately,

regardless of the flipping force.

10. Repeating 8 and 9, delicately shift the variable part of the PF Motor mounting

position to adjust the tension until the tension falls within the allowable standard

value.

5.2.2 PG Adjustment

When any of the following parts has been removed or replaced, this adjustment must

be performed to secure the specified clearance between the print surface of the Print

Head and paper.

Print Head

Carriage Unit

Carriage Shaft

Parallelism Adjust Bushing (Including the case when just moved it)

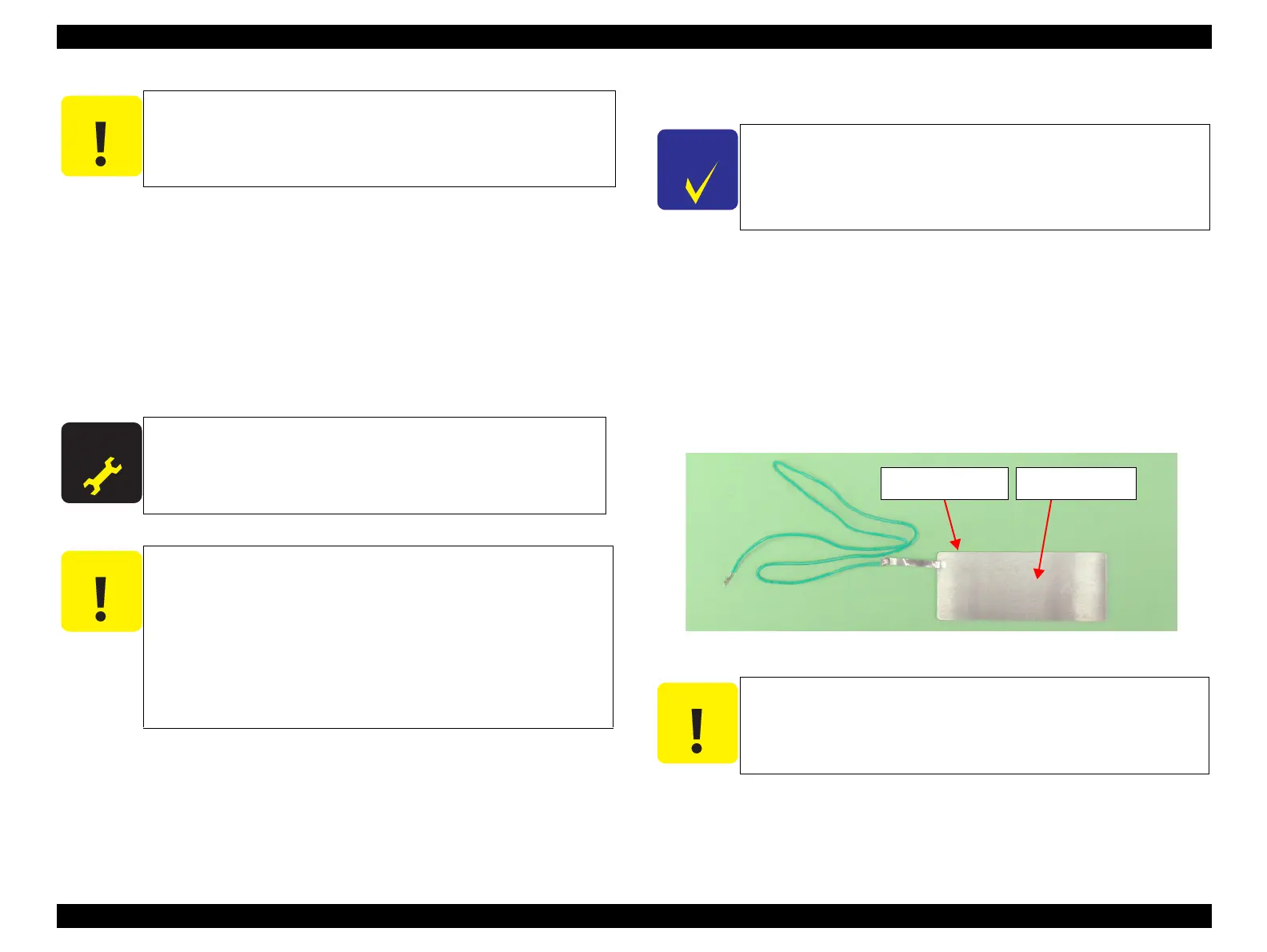

In this adjustment, use the same Adjustment Gauge on the left and right sides.

Figure 5-3. Adjustment Gauge

As the Drive Belt is flipped with the tip of tweezers in the following

steps, carefully choose the flipping position so that the Belt will not

make contact with the Microphone by reaction of flipping.

A D J U S T M E N T

R E Q U I R E D

Standard Value: 10.5 ± 2N (8.5 ~ 12.5N)

Even if the Timing Belt is flipped, the LCD screen may not

change at all. In this case, flip the Timing Belt again after a few

seconds have passed.

If measurement results differ greatly from each other, acoustic

sounds may not be picked up properly in any of the

measurements. Therefore, flip the Timing Belt again with the

tweezers, and record the value at which two measurement

results are approximate. Displaying errors in the range 1/100 to

5/100, the Measuring Tool has high reliability.

Some pictures used in this section are Stylus Photo R1800. The

adjustment method for Stylus Photo R1900/Stylus Photo R2880

is the same as the one for Stylus Photo R1800.

To change the PG position, turn the cam each on the left and

right side of the carriage shaft simultaneously.

Do not touch the Adjustment Gauge Plate surface with bare

hands.

If the Adjustment Gauge Plate surface is stained by ink or, etc.

wipe it with a soft cloth.

Continuity

Measuring Point

Adjustment Gauge

Plate (Top face)

Loading...

Loading...