EPSON Stylus Photo R1900/R2880/R2000/R2000s/SC-P400 Series Revision I

Adjustment Adjustment 155

5.2.4 Colorimetric Calibration

This calibration is performed to compensate the ink discharge amount when the

following parts are replaced:

Print Head

Main Board

PS Board

The following tools are used for this adjustment:

Archival Matte Paper/Enhanced Matte Paper (A4 or letter-size):

1 sheet (for printing Calibration Chart)

Plain paper (A4 or letter-size): 1 sheet (for checking the nozzles)

PC (OS: Windows XP/Me/2000/98)

The following drivers must be installed on the PC:

•

Printer Driver for the model to be adjusted

•

USB Driver for the Calibrator

Calibrator (GretagMacbeth Eye-One with a UV filter)

•

Scanning ruler (supplied with the Calibrator)

•

Calibration plate that contains a white reference tile

(Calibrator accessory)

Colorimetric Calibration Tool (program)

Black paper (A4 size or larger) (A paper printed in solid black can also be

used.)

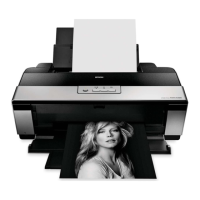

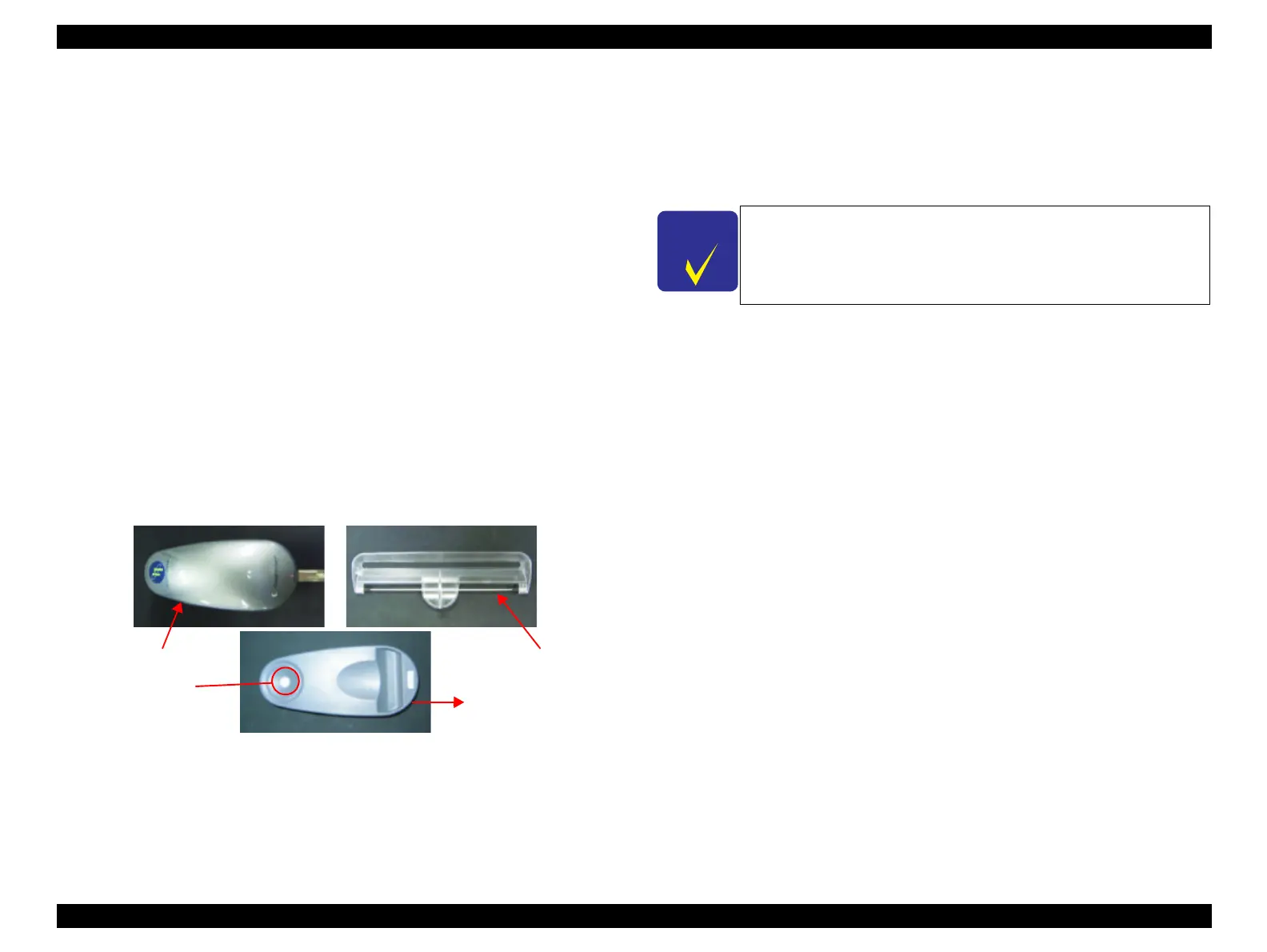

Figure 5-19. The Calibrator and the Accessories

5.2.4.1 Overview of the Colorimetric Calibration

Purpose

Measuring the color of the ink discharge amount information and registering/

controlling this information improves calibration accuracy and ensures consistent

color quality.

To reduce unit-to-unit and mode-to-mode variations in color.

To improve the accuracy of the Ink Counter.

The Color ID can improve the Ink Counter accuracy, which reduces the

running cost of ink.

Colorimetric Calibration Technology

The Principle

The ink discharge amount characteristic of a printer is measured by measuring

color difference (L*a*b*) of a printed chart with a calibrator. Created Color

ID information based on the obtained L*a*b values is stored on the printer.

When printing, the printer sends the Color ID to the printer driver to

compensate the number of ink droplets (dot generation rate) for each of nine

1

different sized droplets of each color. This method allows mass-produced

printers to provide consistent print quality reducing unit-to-unit variation.

Example: Compensation of Ink Amount Ejected from a Print Head

(dot generation rate)

•

When the standard printer generates ten dots.

If the ink discharge amount is insufficient by 10%, this is compensated by

generating 11 dots.

Note 1: Three different sized droplets (small, medium, large) for each of three

waveforms (VSD1, 2, 3)

Head ID

In the conventional color calibration with a Head ID, the print head

characteristics (weight of discharged ink) are measured and compensated. The

following shows the correlation between conventional Head ID adjustment

and Colorimetric Calibration.

Calibrator Scanning Ruler

White

Reference

Tile

Calibration Plate

As color measurement is performed with the fully assembled

product, the electrical characteristics which are unique to each

Main/Power Board are also compensated in addition to the Print

Head.

Loading...

Loading...