TROUBLESHOOTING ST80/ST80L Flow Meter

86 Fluid Components International LLC

7. On the FES-200, dial in a Delta R value with the thumbwheel from the column marked Delta R (ohms) on the Delta R data sheet. Compare to

the output value column (VDC Across 250 Ohms or mA Output as applicable) or the Indicated Display column or both. Verify that the meter

reading is within the stated tolerance of the flow transmitter. See examples 1, 2 and 3 at the end of this section, as applicable.

8. Repeat for each point on the Delta R table, except for the step value and zero value.

9. Turn power OFF and disconnect the FES-200 and DMM. Reconnect the sensor element connector.

10. Close the enclosure, making sure none of the wires are strained. Ensure any seals and gaskets are properly installed.

11. Restore power to the meter.

If you are troubleshooting the flow meter and the readings are good, the flow transmitter is good and the problem may involve the flow

element or interconnecting cable. If the readings are off, a flow element calibration may be required or the flow transmitter needs to be set

up. Contact FCI Customer Service.

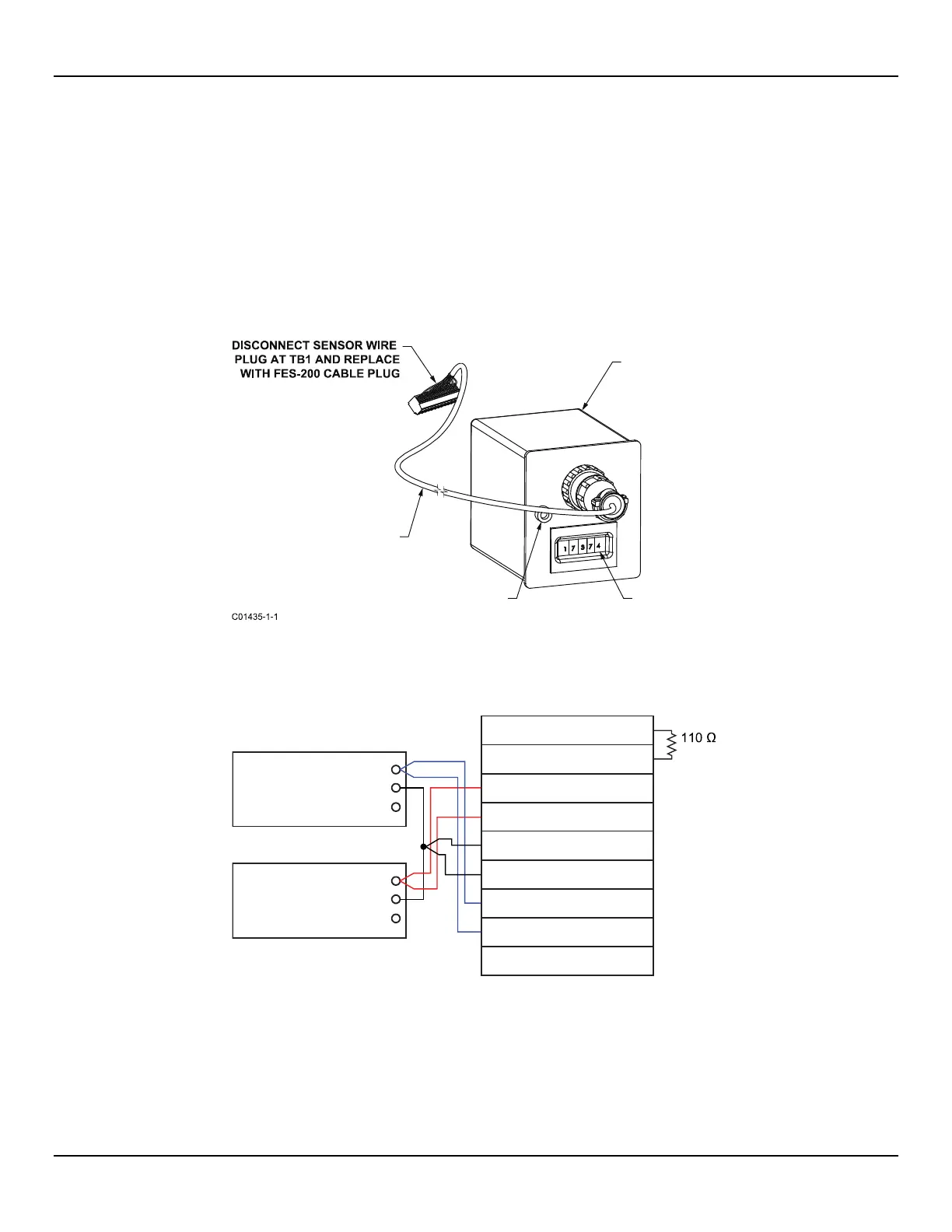

Figure 62 – Connecting FES-200 to ST80/ST80L Transmitter

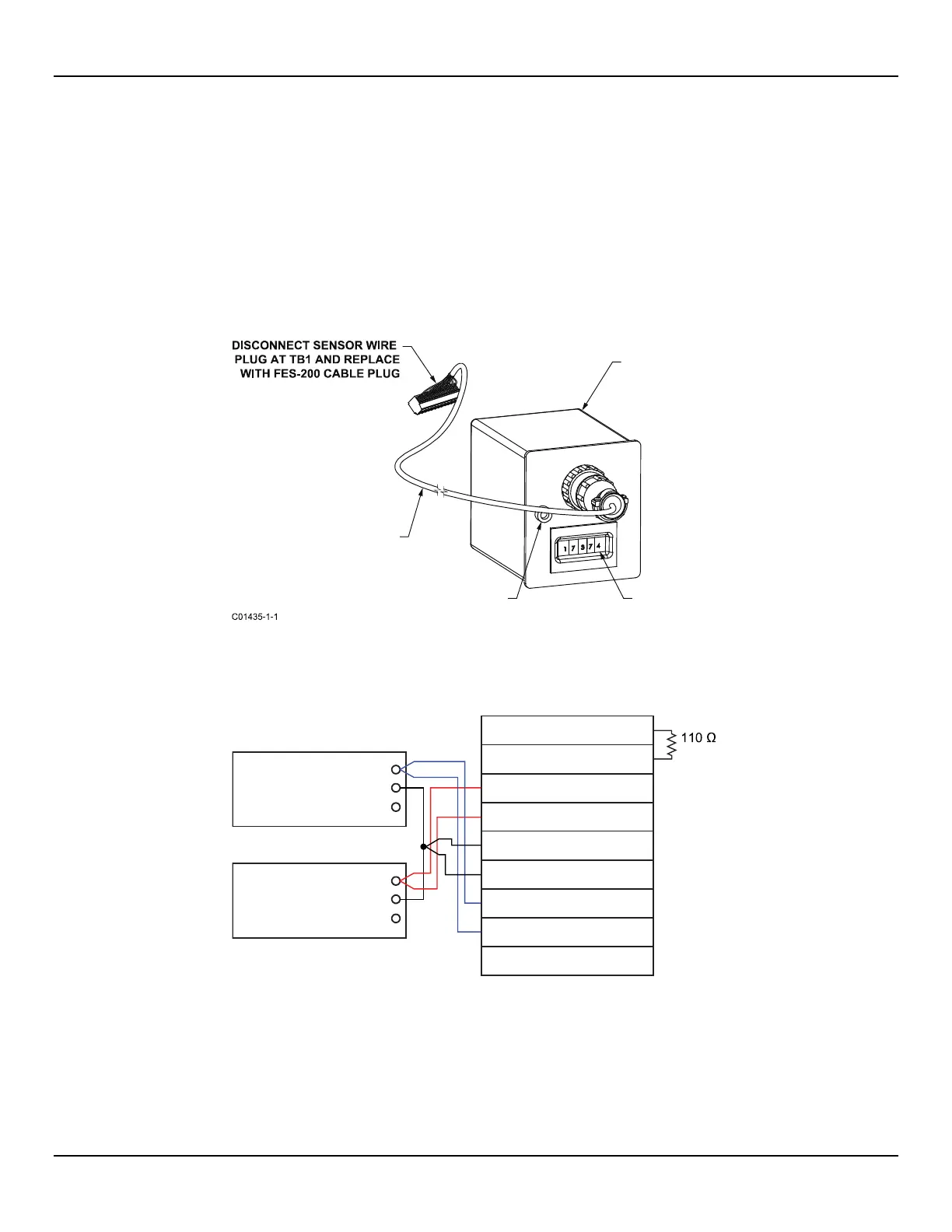

Figure 63 – ST80/ST80L Decade Box Wiring

REMOTE ELECTRONICS

FES-200 CABLE

FOR ST80/ST80L

TP1 HEATER

CURRENT

THUMBWHEEL

SWITCHES

FES-200

FLOW ELEMENT

SIMULATOR

Reference Sens

or

H

L

G

Active Sensor

H

L

G

1 HTR EXC #1

2 HTR RTN

3 ACT EXC

4 ACT SEN

5 GND SEN

6 GND/SHIELD

7 REF EXC

8 REF SEN

9 SHIELD

TB1

10 W

C01436-1-1

Loading...

Loading...