OPERATION ST80/ST80L Flow Meter

66 Fluid Components International LLC

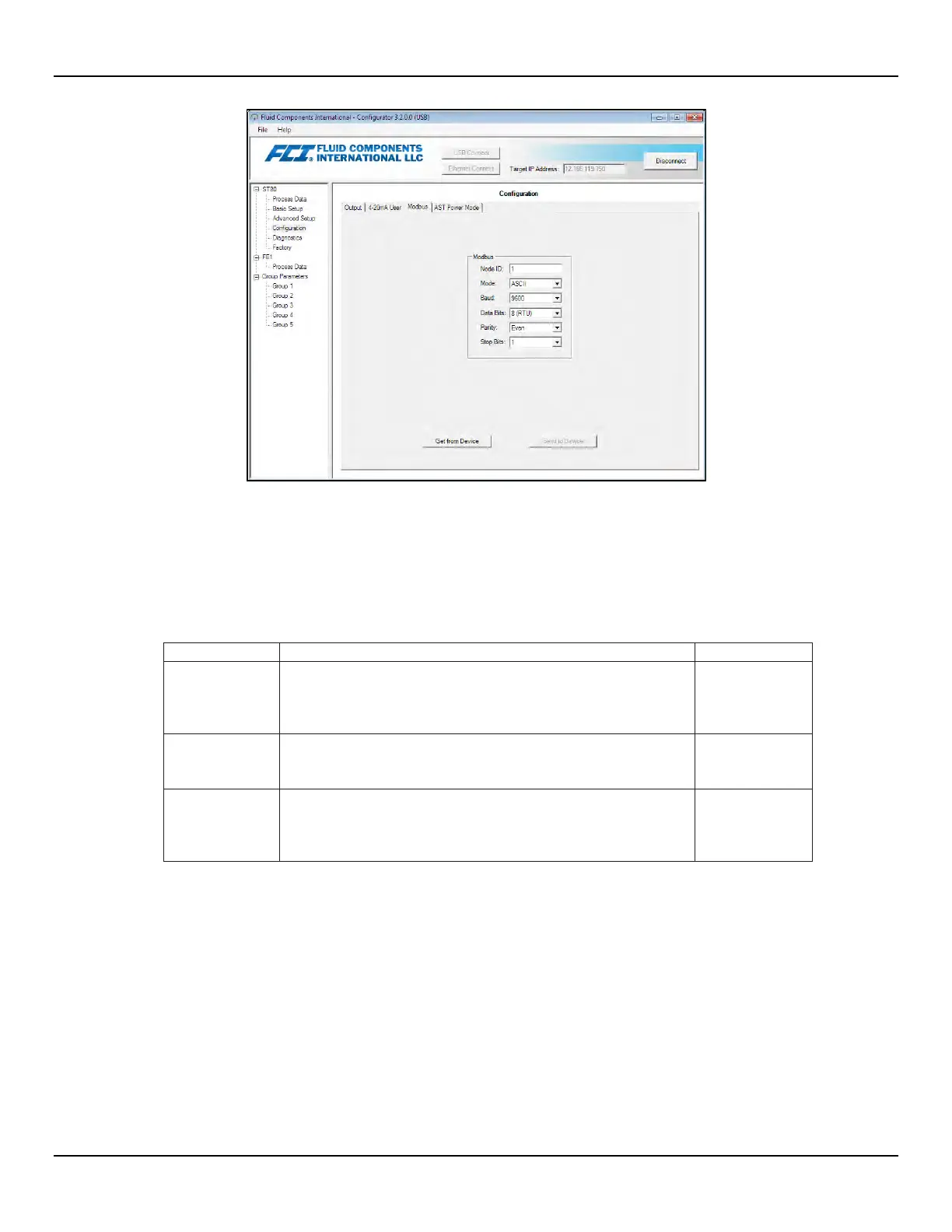

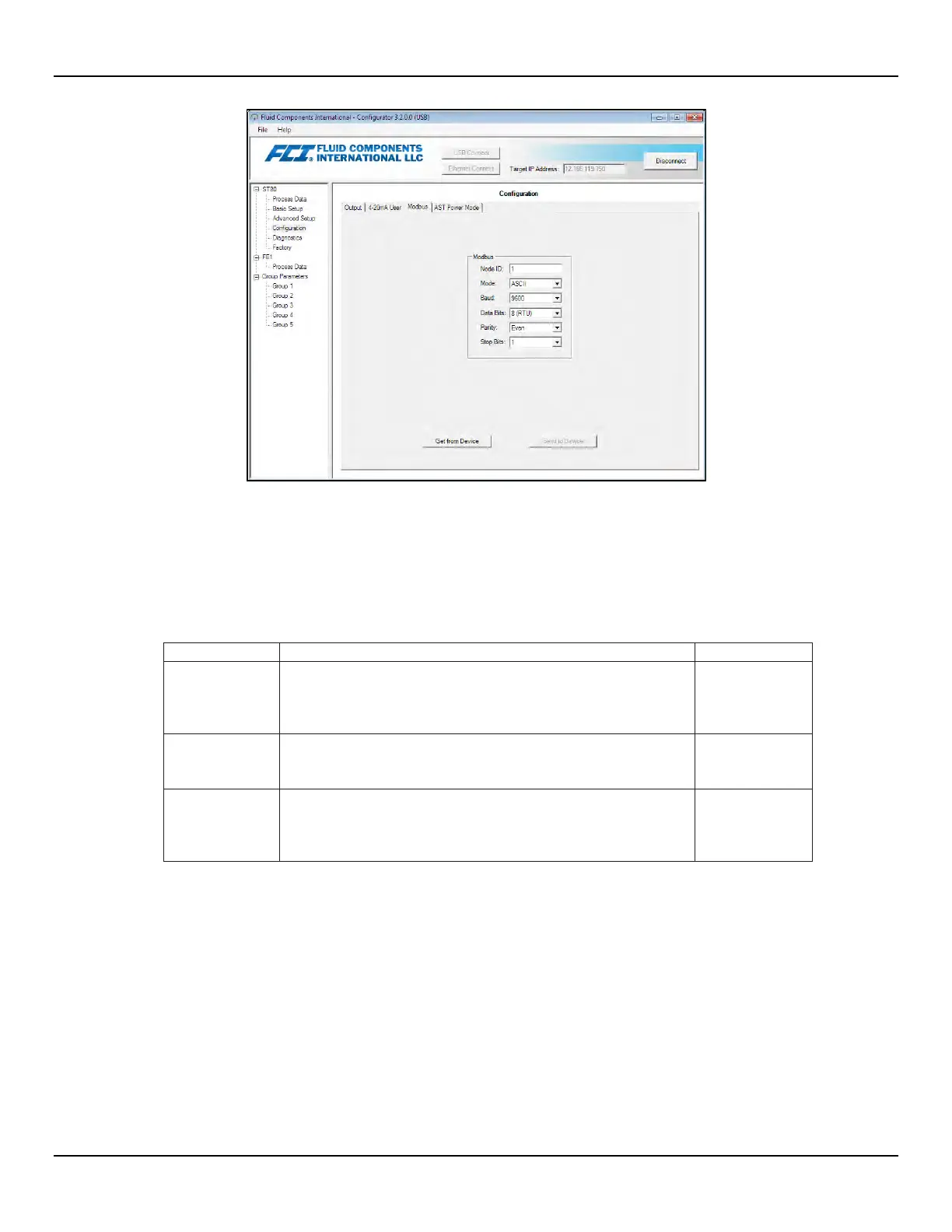

Figure 49 – ST80/ST80L Configuration Software Modbus Tab, Serial Interface Configuration

ST80/ST80L Modbus Commands

With the Modbus protocol the instrument data is read and written via multiple register access. The following public function numbers are

defined for communication with the ST80/ST80L: 03 and 04.

Table 19 – ST80/ST80L Modbus Function Codes

03

• Flow, Temperature, Totalizer, Pressure

• Flow unit, Temperature unit, Totalizer unit, Pressure unit

• Totalizer Enable/Disable Status register

4xxxx

04

• Flow, Temperature, Totalizer, Pressure

• Flow unit, Temperature unit, Totalizer unit, Pressure unit

3xxxx

06

• Reset Totalizer counter

• Enable Totalizer

4xxxx

See Table 22 (page 72), Table 23 (page 73), and Table 24 (page 73) for Modbus engineering unit codes, exception codes, and register

information, respectively.

ST80/ST80L Process Data Registers

Two data type registers are set up in the ST80/ST80L to access the process data. One uses integer data registers (4000) and the other

uses the Daniel extension data registers (5000).

All designated registers must be read for each variable value to extract the floating-point number. Conversion must be started manually

with the 4000 registers. The Daniel extension handles the read and conversion automatically. To use the Daniel extension the master must

support the Daniel extension function.

Totalizer Description

The ST80/ST80L through the Modbus channel offers the flow Totalizer value through three different register groups organized into two

forms of floating point data types. Registers 5103 and 5104, offer the flow Totalizer as a double precision floating point value in the

Modbus Daniel extension protocol. Registers 4105, 4106, 4107, and 4108 offer the flow Totalizer as a double precision floating point value

Loading...

Loading...