IN CASE OF EMERGENCY

248

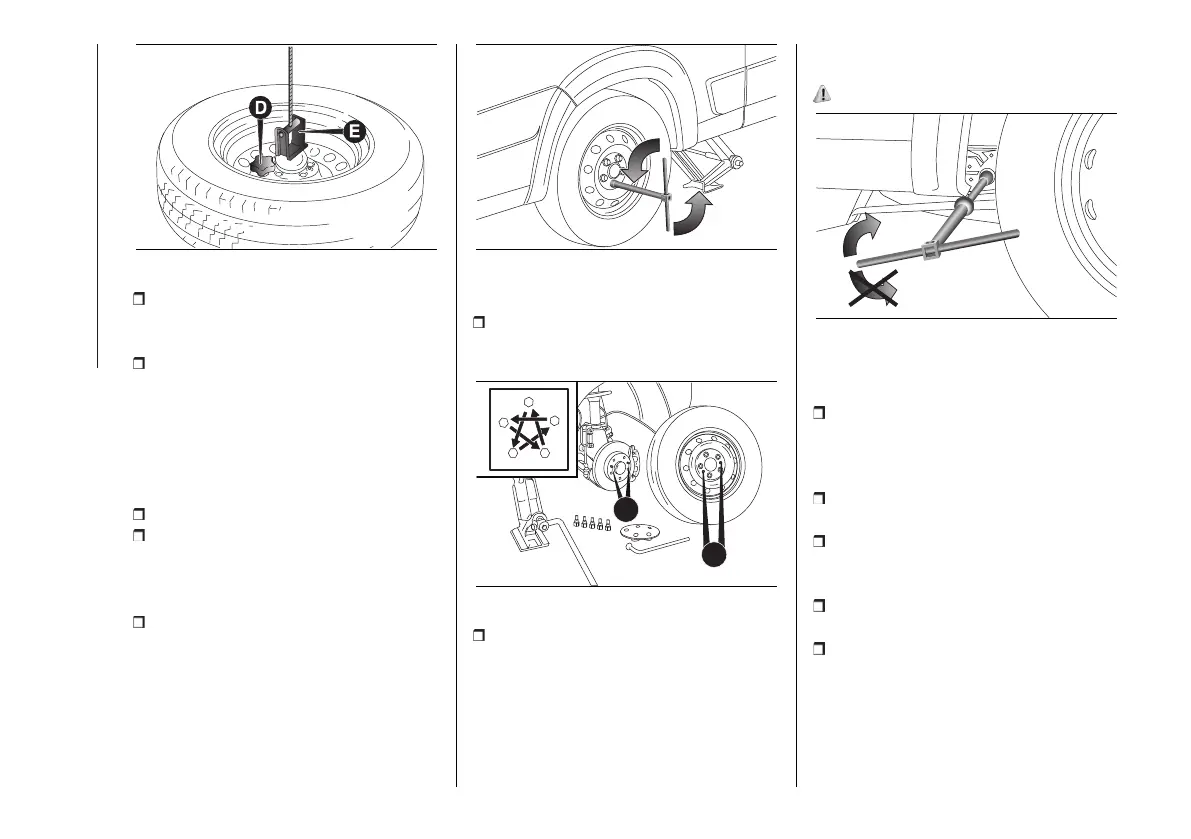

302 F1A0174

with the tools assembled, undo the

bolts fig. 303 fully and remove the

wheel;

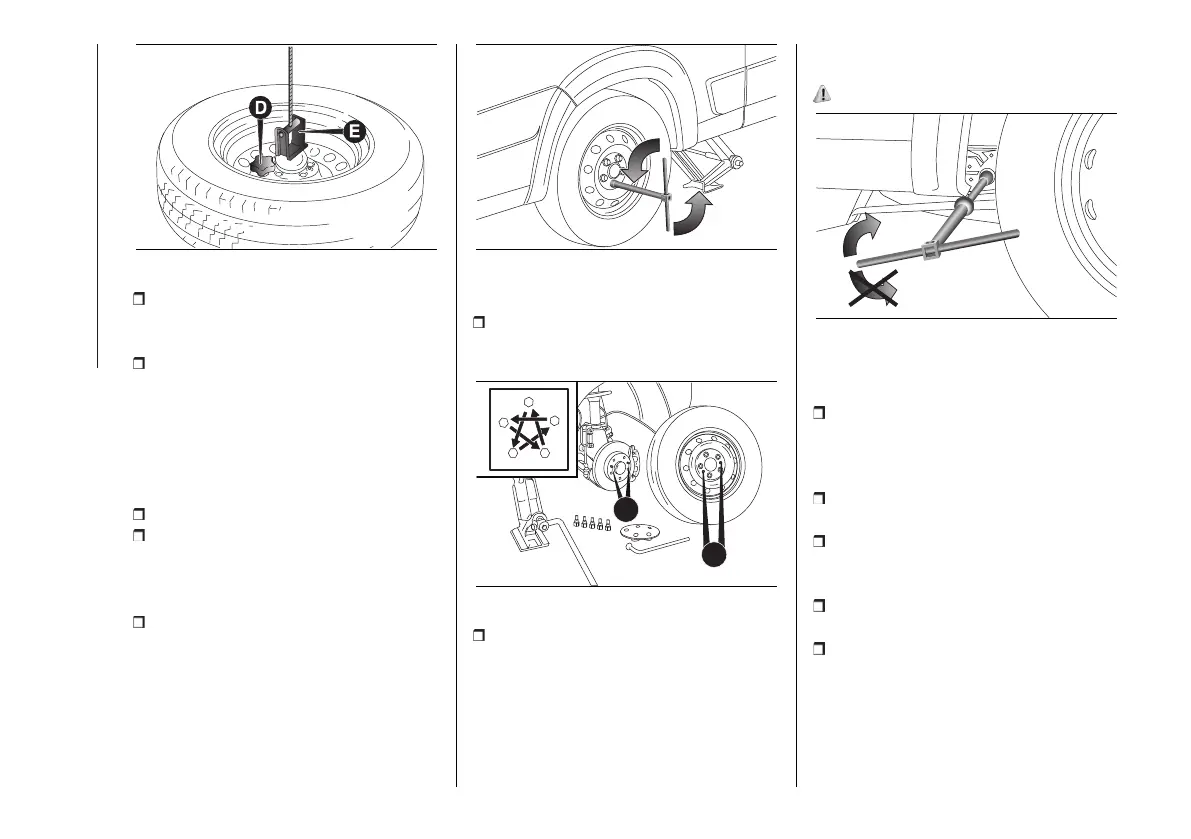

fit the spare wheel, lining up

the holes (G) fig. 304 with the

corresponding pins H. While fitting

the spare wheel, make sure that the

mating surfaces are clean and free of

impurities that could later cause the

fixing bolts to come loose;

screw in the 5 fastening bolts;

assemble the tools to tighten the

bolts fully, passing alternately from one

bolt to the diagonally opposite one,

following the scheme shown in fig. 304;

use the wheel removal wrench to

lower the vehicle and remove the jack.

303 F1A0422

At the end of the operation:

take the replaced wheel, reattach it

to the support (E) fig. 302 and tighten

the knob (D);

304 F1A0176

introduce the assembly tool fig. 301

provided with the suitable extension

(B) fig. 300 on the screw (A) fig. 300 of

the spare wheel housing manoeuvring

device and turn clockwise to lift the

spare wheel back up until it is fully

supported in its housing beneath the

floor pan (D) fig. 301.

202)

305 F1A0430

For vehicles with alloy rims, proceed as

follows:

carry out the above described

operations for changing the wheel until

loading the punctured wheel on the

spare wheel lifting device;

take the kit from the tool bag, located

in the glove compartment;

the kit includes one bracket, three

special screws and one Allen spanner,

10 size;

go to the rear side of the vehicle

where the spare wheel is located;

make sure that all of the cable for

the spare wheel lifting device has been

unrolled, grip the bell and position it

inside the circular bracket fig. 306;

Loading...

Loading...