Diagnosing Copper Cabling Faults

Common Causes of Copper Cabling Failures

6-7

6

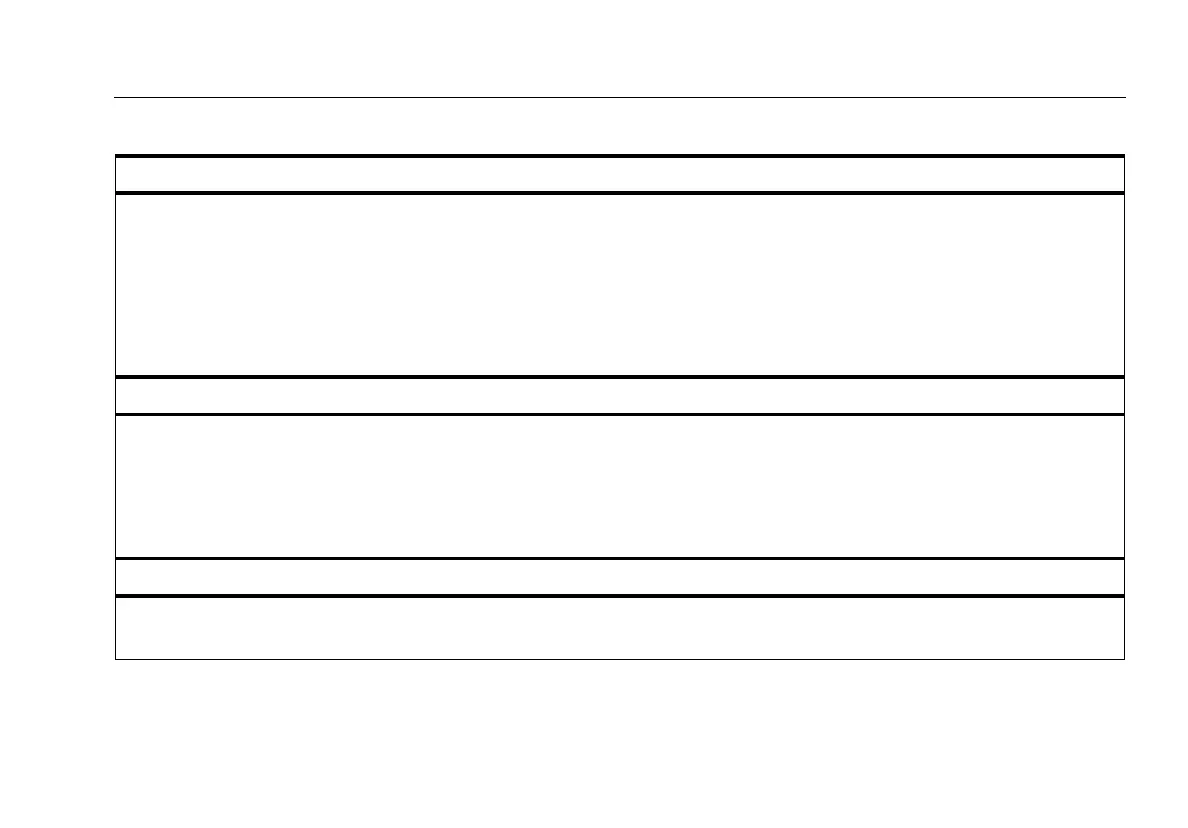

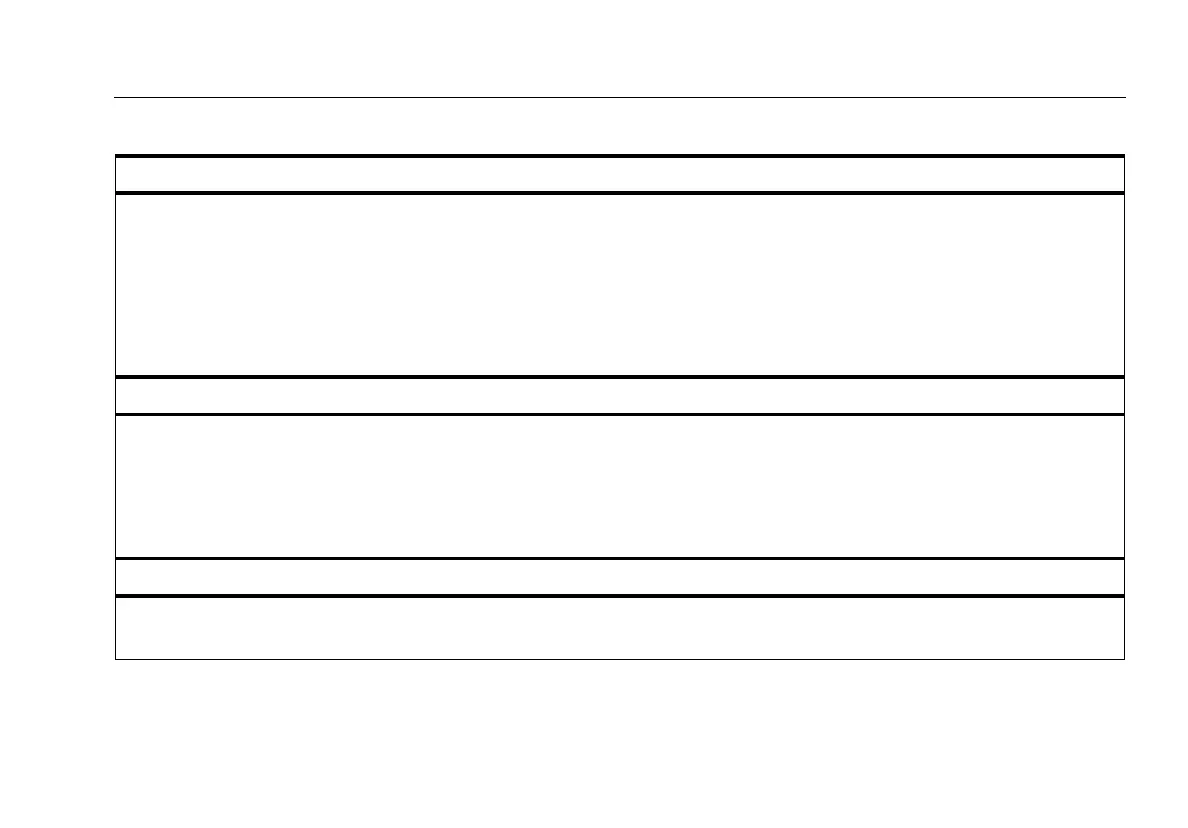

Table 6-1. Diagnosing Twisted Pair Test Failures (cont.)

-continued-

Characteristic impedance exceeds the limit or an anomaly is detected

•

Bad connection

•

Cable compression (tight cable ties, pinches, kinks, etc.)

•

Mismatch of cable types

•

Water in cable jacket

•

Excessive loading at coaxial cable tap

•

Incorrect terminator value (coaxial cable)

Resistance gives FAIL, FAIL*, or PASS* result

•

Cabling is too long

•

Bad connection due to oxidized or loose contacts

•

Wire gauge is too thin

•

Wrong patch cord type used

Tip: The resistance test in Single Test mode features a

scanning function that runs the resistance test

continuously. This function is helpful for locating

intermittent resistance faults. Note that the resistance

test is available in Single Test mode only if the selected

standard has a limit for resistance.

Length gives FAIL result

•

Cable is too long (may need to remove coiled service loops)

•

NVP is set incorrectly

Loading...

Loading...