36

Fig. 14

Fig. 11 Rear view

Mains cable

2x400V / 50Hz

Plug-in connection for

water return-flow (red)

Plug-in connection for

water forward-flow (blue)

PUTTING THE COOLING UNIT INTO OPERATION

Open the twist-action lock and pull out the drawer containing

the coolant reservoir (see Fig. 13)

Undo the screw cap from the reservoir.

Before starting up the unit, always check the water level and the

quality of the water.

Top up with cooling water, up to the level of the water return-

flow opening.

ONLY USE CLEAN TAP WATER!

Add pure alcohol to the coolant, for both summer and winter

operation (see Table 1 for recommended mixing ratio).

The electrical conductivity of all other anti-freeze agents makes

them unsuitable for use here.

After switching the machine on (see "Start-up" on p. 48-50),

check the water circulation until water can be seen returning

unobstructed into the coolant container. If this does not occur,

bleed the air bubbles out of the forward-flow tubing:

How to bleed:

With the water pump running, pull back the retaining ring on

the blue plug-in connector (Fig. 11) and unplug the forward-

flow hose.

Using a wooden or plastic pin, briefly push in, and then release,

the conical nipple in the middle of the plug connector

(N.B. do not damage the sealing surface).

If no water comes out, repeat the procedure until all the air-

bubbles have been forced out and coolant is discharged when

the conical nipple is pushed in.

Plug the water forward-flow hose back in, and secure it.

Screw the cap back onto the coolant reservoir.

Push the drawer containing the coolant reservoir back in and

secure it with the twist-action lock.

Check that the water connections are watertight.

Mains voltage - pump motor

Current input

Speed

Protection

Cooling capacity

Throughput

Throughput pressure

Coolant volume

Dimensions (lxwxh)

Weight (not including coolant)

2x380V/400V/415V~ 50Hz

0,56 A

2800 R/min.

IP23

1,6 KW

5,2 l/min.

3,2 bar

ca. 5 l

575x365x265 mm

21 kg

TECHNICAL DATA

Mixing ratio

External temperature

Water Alcohol +° to -5°C -10°C

-15°C

-20°C

1,75 l

3,5 l 1,5 l

3,25 l

3,75 l 1,25 l

4,0 l

1,0 l

Table 1

Fig. 13

Topping-up opening

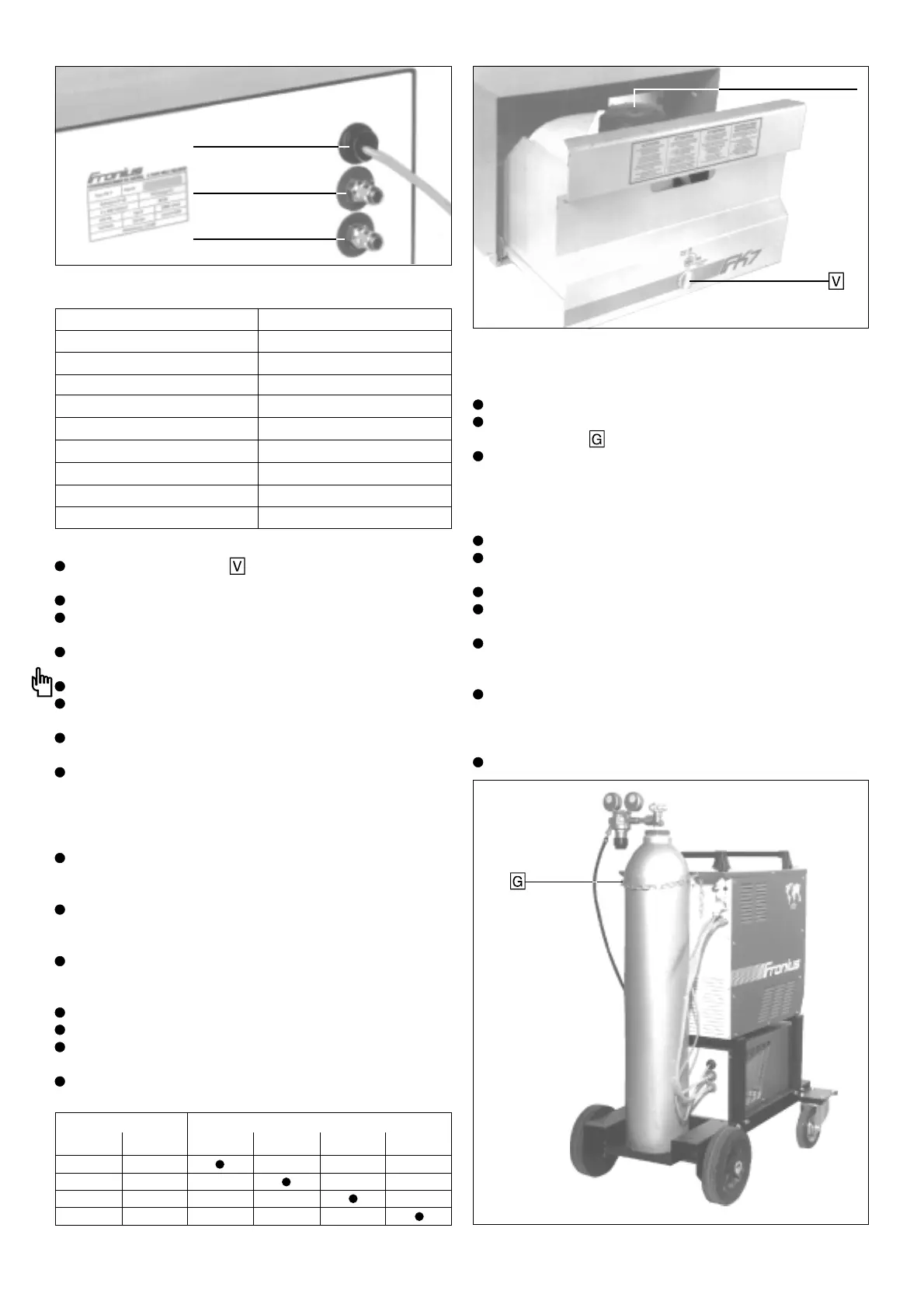

MOUNTING AND CONNECTING THE

SHIELDING-GAS CYLINDER:

Place the gas cylinder on the platform

Secure the cylinder to the rear of the machine by means of the

fastening chain

N.B.: To ensure adequate safety, the fastening chain must be

fixed around the upper third of the cylinder (but not around its

neck). If this is not possible, because the welding machine set-

up is not tall enough, e.g. at a gascooled unit, then - for safety

reasons - a smaller cylinder (e.g. 20 l) must be used.

Remove the protective cap from the gas cylinder

Give the cylinder valve a quick turn in an anticlockwise direction,

so that the gas jet removes any dirt which may have accumulated

Check the seal on the pressure regulator

Screw the pressure regulator onto the gas cylinder and tighten

using a 30 mm open-ended spanner

Screw the knurled nut of the gas hose onto the gas connection

on the power source, and tighten by hand (Fig. 14).

(N.B. first check that an O-ring seal has been inserted).

Connect the unit’s gas hose to the pressure regulator. Give the

thumb screw on the underside of the pressure regulator 2 to 4

turns in an anti-clockwise direction (this prevents damage to

the pressure regulator when the cylinder valve is opened)

Set the gas flow rate (see “TIG welding: Start-up” on p.48)

Loading...

Loading...