4.8 Configuring Function Codes for Drive Controls

4-27

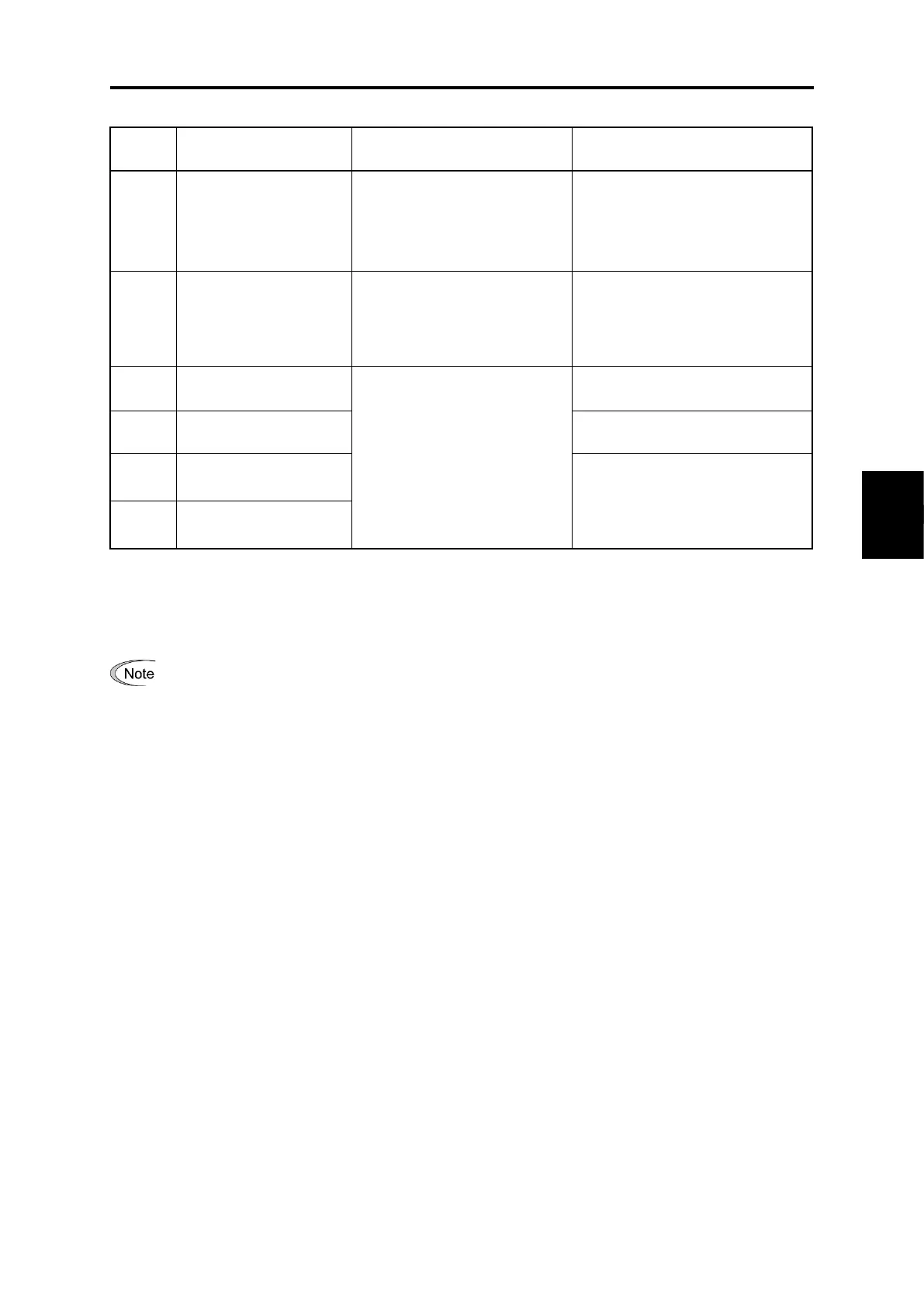

Table 4.8-11 Cont.

Synchronous motor 1

(iron loss factor)

Set “the iron loss described in

motor test report divided by

Motor rated capacity: p 02 *”.

Set 0%, if the iron loss is

unknown.

Fuji standard synchronous motor

(GNB2 series) constant

Synchronous motor 1

(overcurrent protection

level)

Set the demagnetization limit

current. Set to prevent

demagnetizing the motor. If it is

unknown, set approx. 200% of

motor rated current.

Fuji standard synchronous motor

(GNB2 series) constant

Machine design values

(Note) For the test run of the

motor, increase values so that

they are longer than your

machine design values.

If the specified time is short, the

inverter may not run the motor

properly.

Please refer to Table 4.4-1 Initial

value for each destination

Frequency limiter (upper

limit)

Acceleration time 1

(Note)

FRN0115G2S-2G/FRN0060G2■

-4G or below: 6.00 (s)

FRN0146G2S-2G/FRN0075G2■

-4G or above: 20.00 (s)

Deceleration time 1

(Note)

(3) Performing tuning (synchronous motors)

Perform tuning in accordance with the "4.8.2 [ 3 ] Synchronous motor tuning method”.

If a filter other than the Fuji optional output filter (OFL-□□□-□A) is connected to the inverter's output

(secondary) circuit, the tuning result cannot be assured. When replacing the inverter connected with such

a filter, make a note of the old inverter’s settings for the primary resistance %R1, leakage reactance %X,

no-load current, and rated slip frequency, and specify those values to the new inverter’s function codes.

Vibration that may occur when the motor's coupling is elastic can be regarded as normal vibration due to

the output voltage pattern applied in tuning. The tuning does not always result in an error; however, run

the motor and check its running state.

Loading...

Loading...