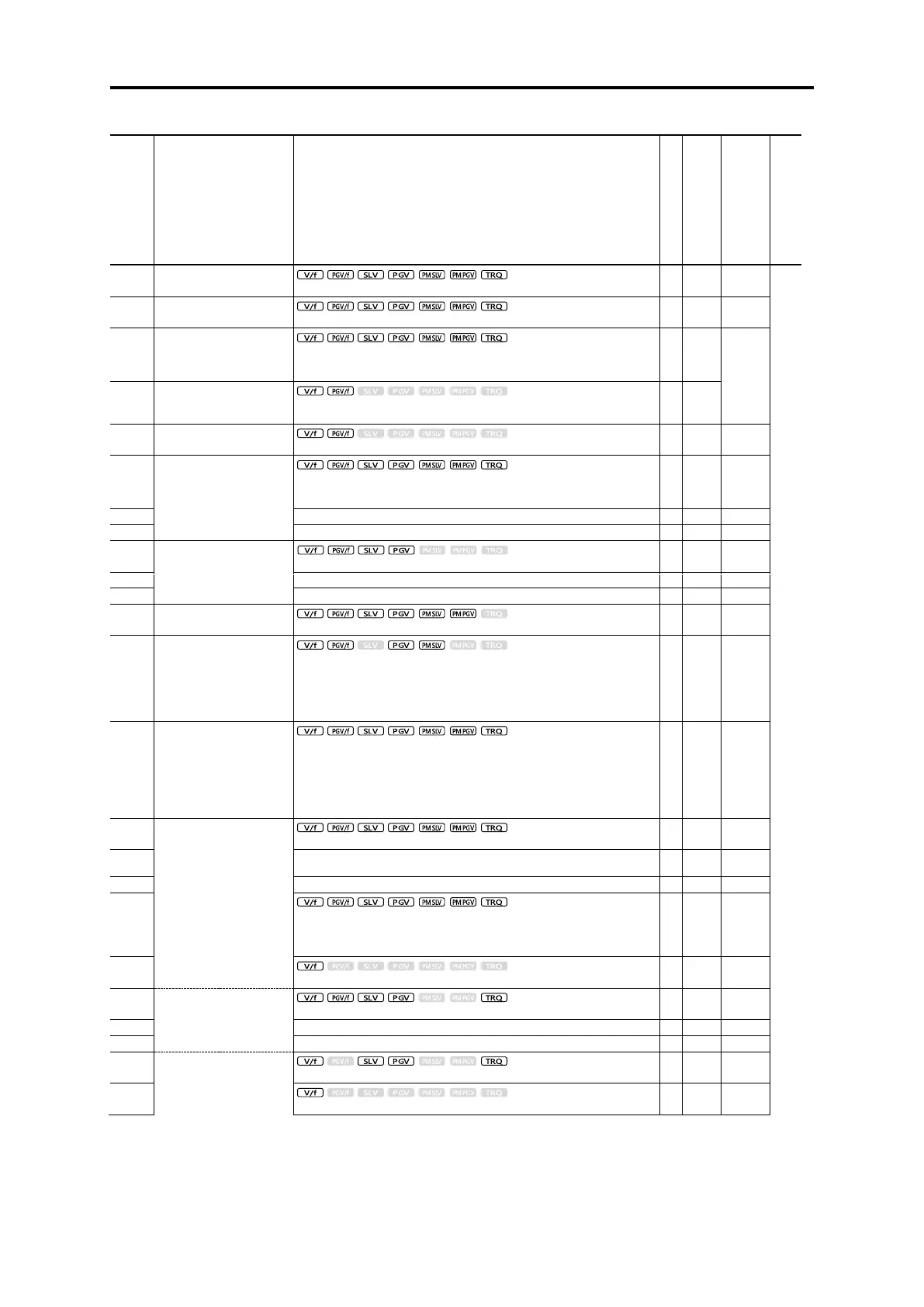

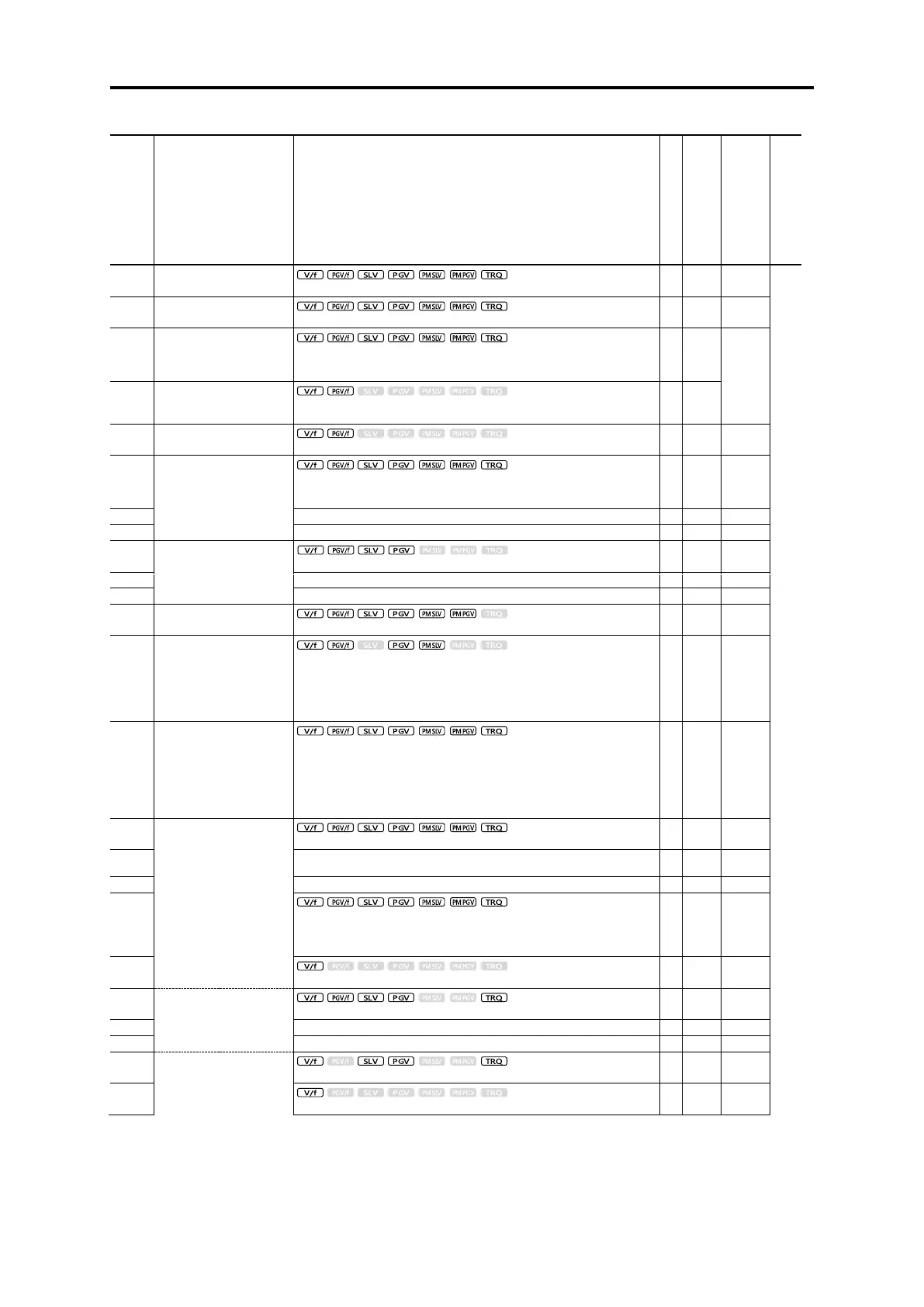

5.2 Function Code Tables

[ 6 ] A codes: Motor 2 Parameters (Motor 2 parameters)

Control method and Data setting range

Maximum output frequency

2

Rated voltage at base

frequency 2

0: AVR disable (output voltage proportional to power voltage)

80 to 240 V: AVR operation (200 V series)

160 to 500 V: AVR operation (400 V series)

80 to 240 V: AVR operation (200 V series)

160 to 500 V: AVR operation (400 V series)

0.0 to 20.0 % (% value against base frequency voltage 2)

Electronic thermal overload

protection for motor 2

(Select motor

characteristics)

1: Enable (for a general-purpose motor with self-cooling fan)

2: Enable (for an inverter-driven motor with separately powered cooling

fan)

0.00 (disable), current value of 1 to 135 % of inverter rated current

DC braking 2

(starting frequency)

0 to 100 % (HHD specification), 0 to 80 % (HND specification)

0.00 (disable): 0.01 to 30.00 s

Load selection/

Auto torque boost/

Auto energy-saving

operation 2

0: Quadratic-torque load

1: Constant torque load

2: Auto torque boost

3: Auto energy-saving operation (quadratic-torque load)

4: Auto energy-saving operation (constant torque load)

5: Auto energy-saving operation with auto torque boost

Drive control selection 2

0: V/f control without slip compensation

1: Dynamic torque vector control

2: V/f control with slip compensation

3: V/f control with sensor

4: Dynamic torque vector control with sensor

5: Sensorless vector control

6: Vector control with sensor

0.01 to 1000 kW (when A39 = 0,2 to 5)

0.01 to 1000 HP (At P39 = 1)

0: Disable

1: Tune the motor while it is stopped

2: Rotation tuning

5: Stop tuning (%R1, %X only)

(Slip compensation gain for

driving)

(Slip compensation

response time)

Loading...

Loading...