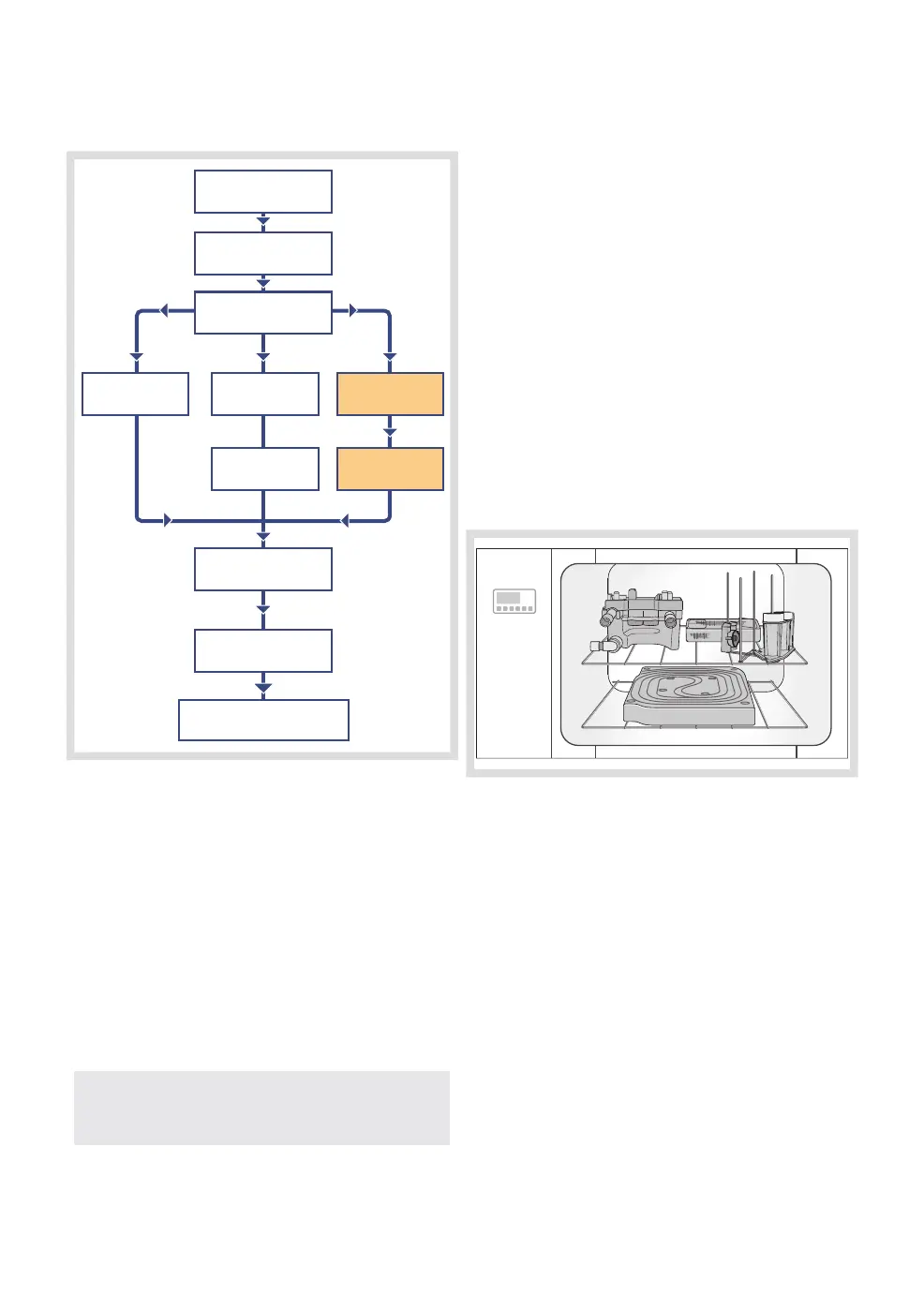

12.8 Steam autoclaving procedure

Dismantle

Wipe off/discard

Rinse

DryDisinfectant

Rinse

Washer-

disinfector

Dry

Assemble

System checkout

Steam

autoclave

A steam autoclave can be used to disinfect

the patient cassette, volume reflector and

associated parts.

Rinse and dry the equipment prior to this

procedure. Water remaining in the patient

cassette can prevent complete energy transfer

from the hot steam, resulting in an incomplete

process.

For drying alternatives, see page 253.

CAUTION: Steam autoclaving will reduce

the lifetime of the components.

12.8.1 Steam autoclave

• System parts should be autoclaved in a

validated process, typically at a temperature

of 121°C (250°F) for 15 minutes or 134°C

(275°F) for 4 minutes.

• The system parts can also be autoclaved

at a temperature of 134°C (275°F) for 18

minutes, a.k.a the Prion autoclave program.

Using this method will further reduce the

lifetime of the parts.

• The breathing bag and suction bottles

should be autoclaved according to the

manufacturer's instructions.

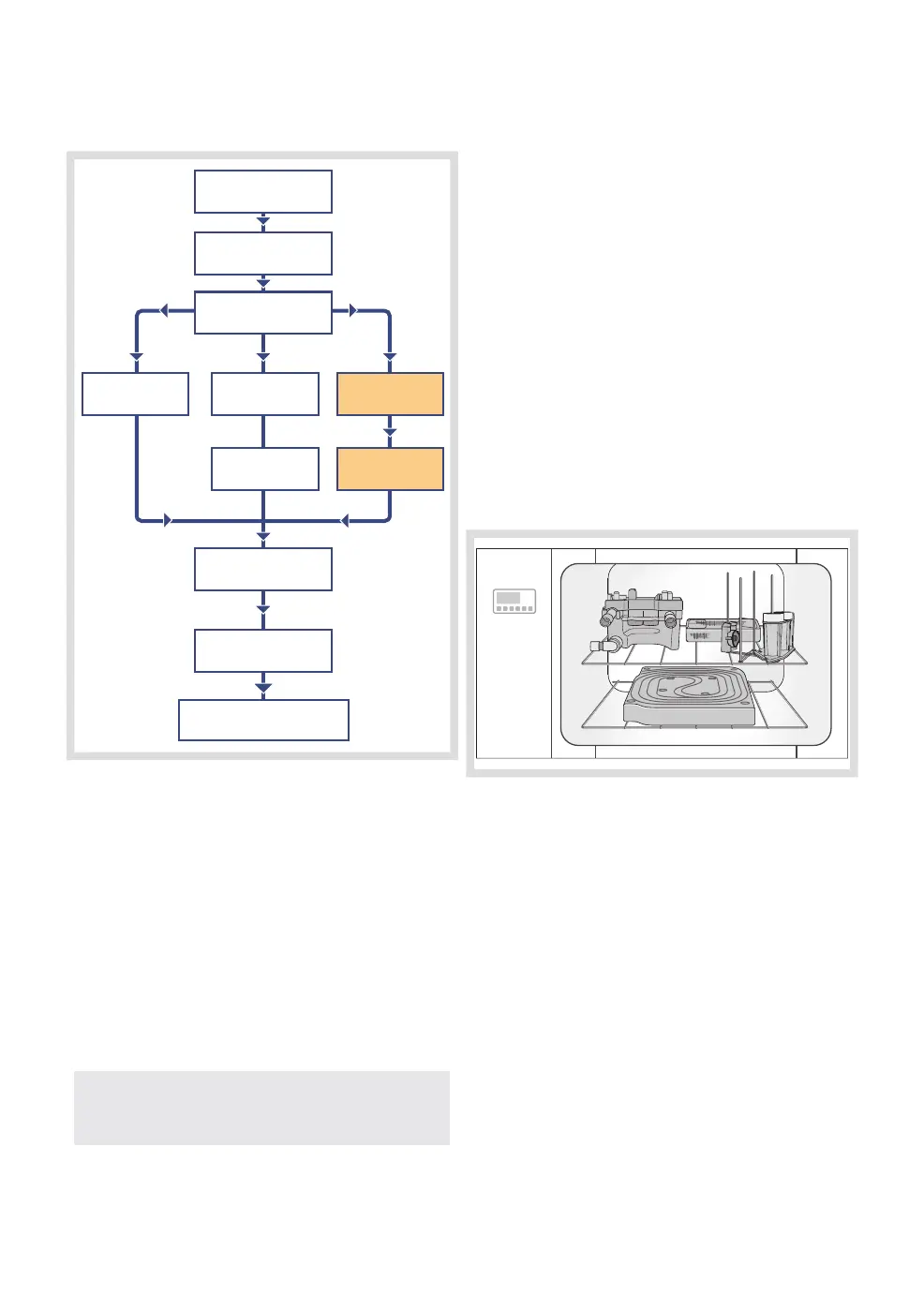

Position the parts inside the autoclave:

The patient cassette and volume reflector have

been tested to withstand:

• 100 autoclaving cycles with a 4 minute

holding time at 134ºC (275°F).

• 50 autoclaving cycles with an 18 minute

holding time at 134ºC (275°F).

252

FLOW-i 4.2, User's Manual

| 12

| Routine cleaning and maintenance |

Loading...

Loading...