Multec 3.5 Injectors

1.Description and Working Principle

The Multec 3.5 Fuel Injector is an electromechanical device. A magnetic field is generated as

voltage is applied to the solenoid coil.

The resulting magnetic force lifts the core assembly, overcoming manifold vacuum, spring force,

and fuel pressure, allowing fuel to pass through the ball and seat interface to the director.

As the fuel passes through the director, an atomized spray is developed. The injector closes

when the voltage is removed, cutting off the fuel flow.

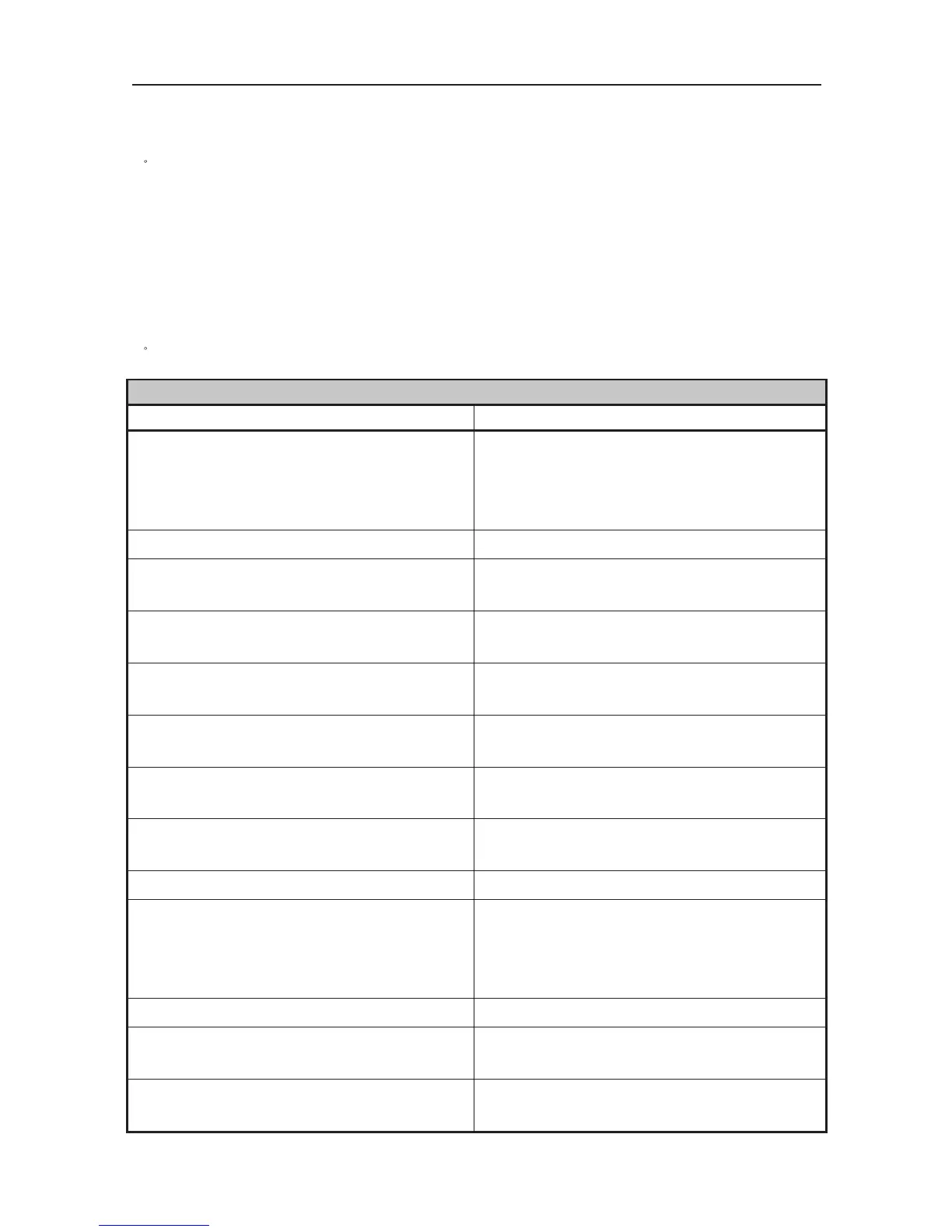

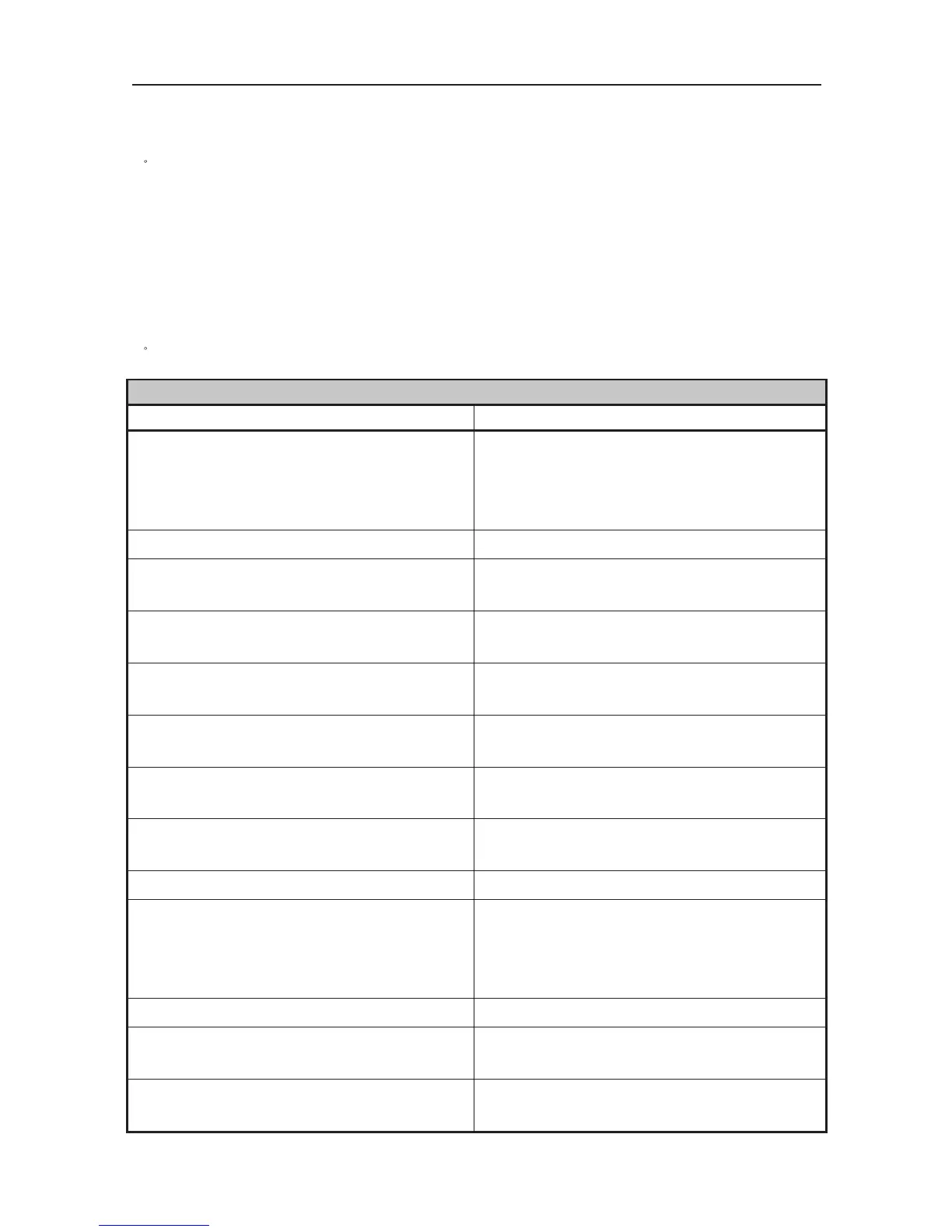

2.Handling - DOs & DONTs

3.5 FUEL INJECTOR HANDLING

DO NOT: Re-use injector seal rings if at all

possible. If no other choice exists, take

extra care in inspecting the seal rings for

damage.

Leakage.

DO NOT: Dip injector tips into lubricants. Can plug injector spray orifices.

DO NOT: Cycle injector repeatedly without

fuel pressure.

Damage to internal mechanical components.

DO NOT: Pulse (actuate) a suspected high

leak rate injector (leak >50 sccm air).

Can dislodge internal contamination if

present and preclude root cause analysis.

DO NOT: Allow water to enter fuel system

from air lines, etc. during leak checks.

Can damage injectors.

DO NOT: Contact or apply load to the

injector tip for installation.

Apply load to 45 deg angle on nylon over

mold see

DO NOT: Pound injectors into manifold

during assembly to engine.

Can damage injectors or seal rings.

DO NOT: Apply excessive side loads to

electrical connectors.

May cause loss of electrical continuity.

DO NOT: Use any dropped unit.

Internal damage may have occurred.

DONOT: Store injectors, rails, or

subassemblies including engines on which

the injectors have been installed in an

unprotected environment.

External contamination can damage the

injector electrically and/or mechanically.

DO NOT: Use the injector as a handle. Do not use the injector to lift assemblies

DO NOT: Rack, stage, or handle parts in a

manner that allows contact between parts.

Damage will occur.

DO NOT: Remove packing in a way that

allows contact between parts.

Damage could occur due ton contact

between parts.

Loading...

Loading...