6-38

6.5 Faults that invoke no on-screen indications

6.5.1 Chipped print (lower dots)

※CAUTION

1.

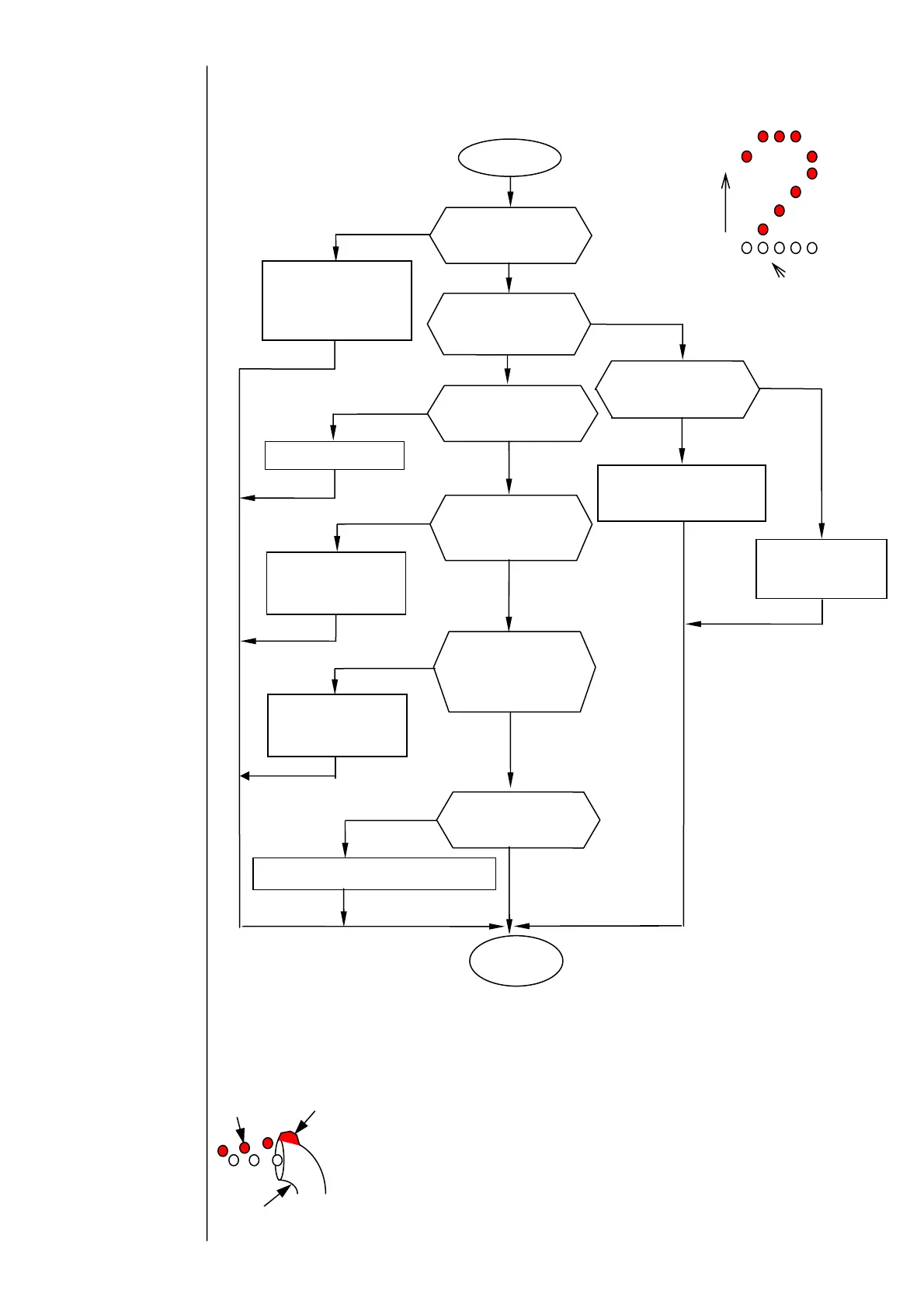

If the ink beam is not centered with respect to the gutter,

dots having a small amount of deflection (lower dots of

characters) may collide against the gutter and fail to jet out

of the nozzle head, thereby causing chipped prints.

Position the ink beam at the center of the gutter.

2.If the ink pressure rises, the ink beam flow rate increases

to decrease the amount of deflection, causing dots having a

small amount of deflection to collide against the gutter and

producing chipped prints. Ensure that the ink pressure

setting is within the specified limits.

Gutter

Ink/foreign

matter

Print

particle

Chipped print

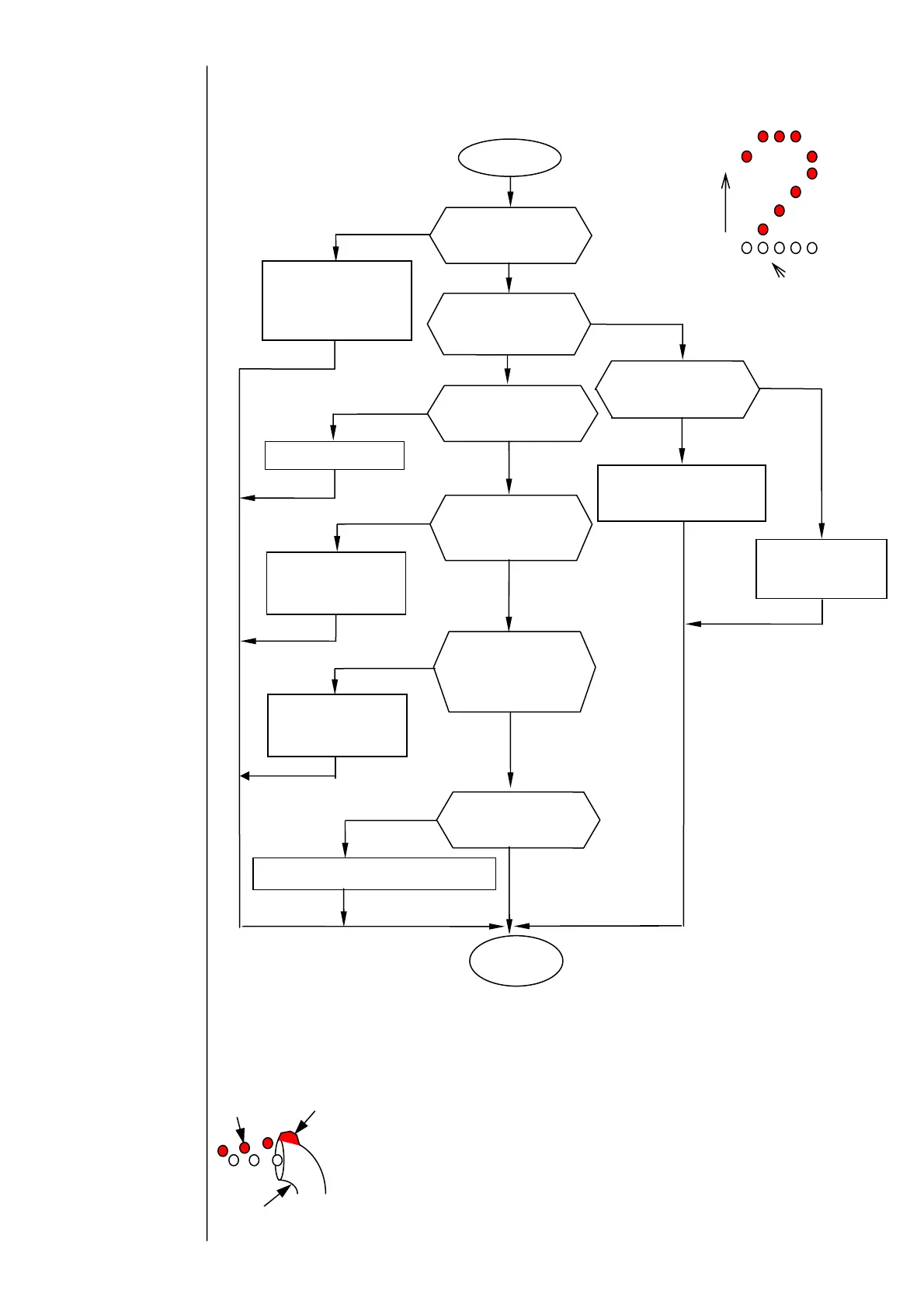

Replace the ink.

Adjust the ink beam

position so that the ink

beam is centered with

respect to the gutter.

No

Is the ink beam

positioned at the

center of the gutter?

es

Is the ink pressure

higher that the

s

ecified limit?

No

es

Has the cumulative

ink use time exceeded

the life limit?

No

es

Resume the

operation.

Pour the makeup ink

over the gutter edge

section to clean it.

Is there ink or dirt

buildup on top of the

gutter edge section?

es

No

Replace the EZJ94 board / EZJ106 board.

es

Is the charged

voltage output

correctly?

No

Adjust the ink

pressure until it is

within the limits.

Can the ink pressure be

adjusted?

No

es

Provide pressure relief,

then replace the

pressure-reducing valve.

Direction of

deflection

Missing dots

Is the contact of

fastening tab in

high-voltage power

supply HV-OUT

Unplug the fastening

tab, and then plug it

in properly.

es

No

Loading...

Loading...