4-15

4.9 Viscometer Replacement Procedure

4.9.1 In the case where an abnormality arises to the viscometer, the following action

is necessary.

Note: In the case where the viscometer is abnormal, it operates by a dot count

method.

①Viscometer variation abnormality

Cause : Foreign substance mixing

Treatment : (a) To replace the viscometer filter. If it does not recover, perform (b).

(b) To disassemble and clean the viscometer. If it does not recover,

perform (c).

(c) To replace the viscometer.

②Viscometer measured value abnormality

Cause : Ink retention inside the viscometer. Treatment: To disassemble and

clean the viscometer.

Cause : Proximity sensor failure. Treatment: To replace the proximity sensor.

Cause : High (low) viscosity of the ink. Treatment: To replace the ink.

If it does not recover by the above treatment, replace the viscometer.

③Viscometer temperature detection abnormality

Cause :Temperature thermistor failure.

Treatment: To replace the thermistor.

4.9.2 Replacement of viscometer

"Caution" Turn the power OFF before operation.

Otherwise, abnormalities occur.

①Drain the ink from the main ink tank.

(Ref. "Ink drainage" at "Circulation Control" screen)

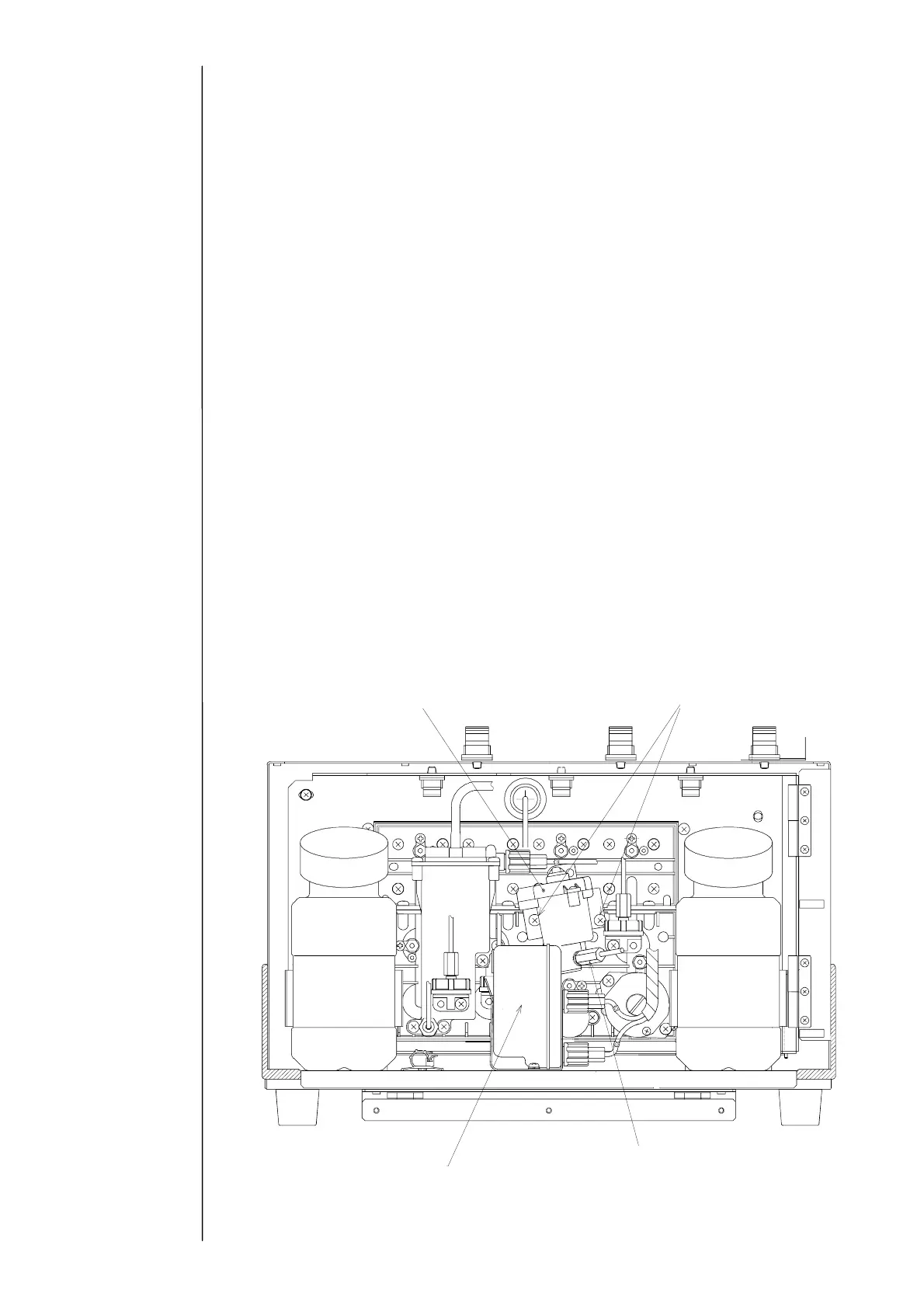

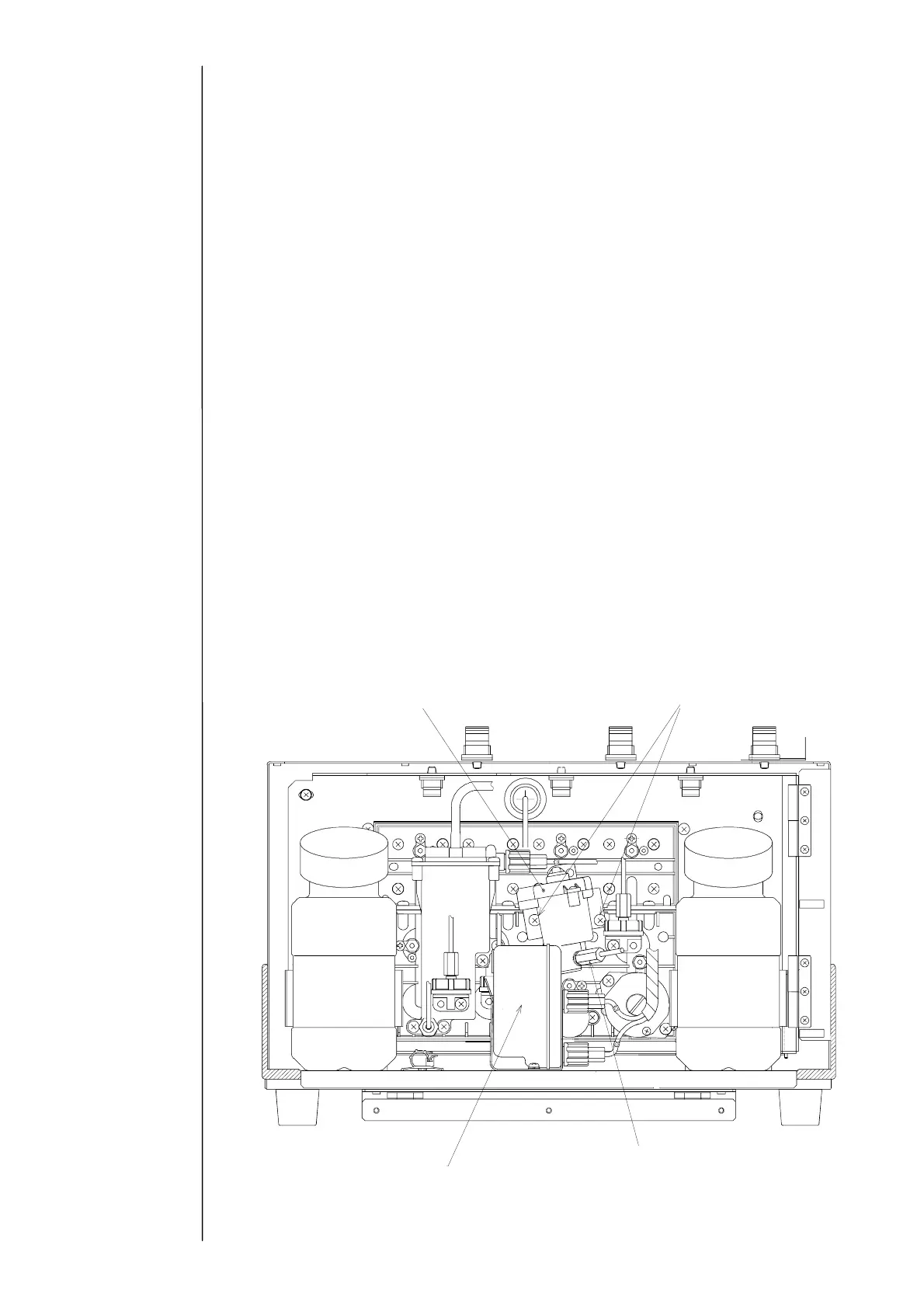

②Draw the ink filter so as to bring the viscometer into sight.

③Disconnect the connector of the respective lead wires of the proximity sensor (4 pins),

the thermistor (2 pins, No.2 is black) and the coil (2 pins, No.2 is blue) on the back

surface of the unit.

④Remove the viscometer IN side tube (mark G) by giving the tube block a turn to the

left.

iscometer

Two viscometer setscrews

Ink filter

Viscometer IN side tube (mark G)

Loading...

Loading...