3. Operation

224

[2] Calibration of Loadcell (CLBR, CEND)

A loadcell with no load is set to 0 [N] at shipment.

Do not fail to conduct a calibration when the condition that a pressing tool such as a pusher is

attached is set to the origin (0 [N]).

Just before highly precise pressing, provide readjustment and inspection depending on the

condition.

Calibration can be performed from a teaching tool such as PC software. [Refer to the

Instruction Manual of each teaching tool for details.]

Input Output

PIOsignal

CLBR CEND

Example of calibration

Caution: In the example described below, a tool with 100kg is used, however, make the

tool weight 10kg or below to fix on the tip of the loadcell unit in the actual use.

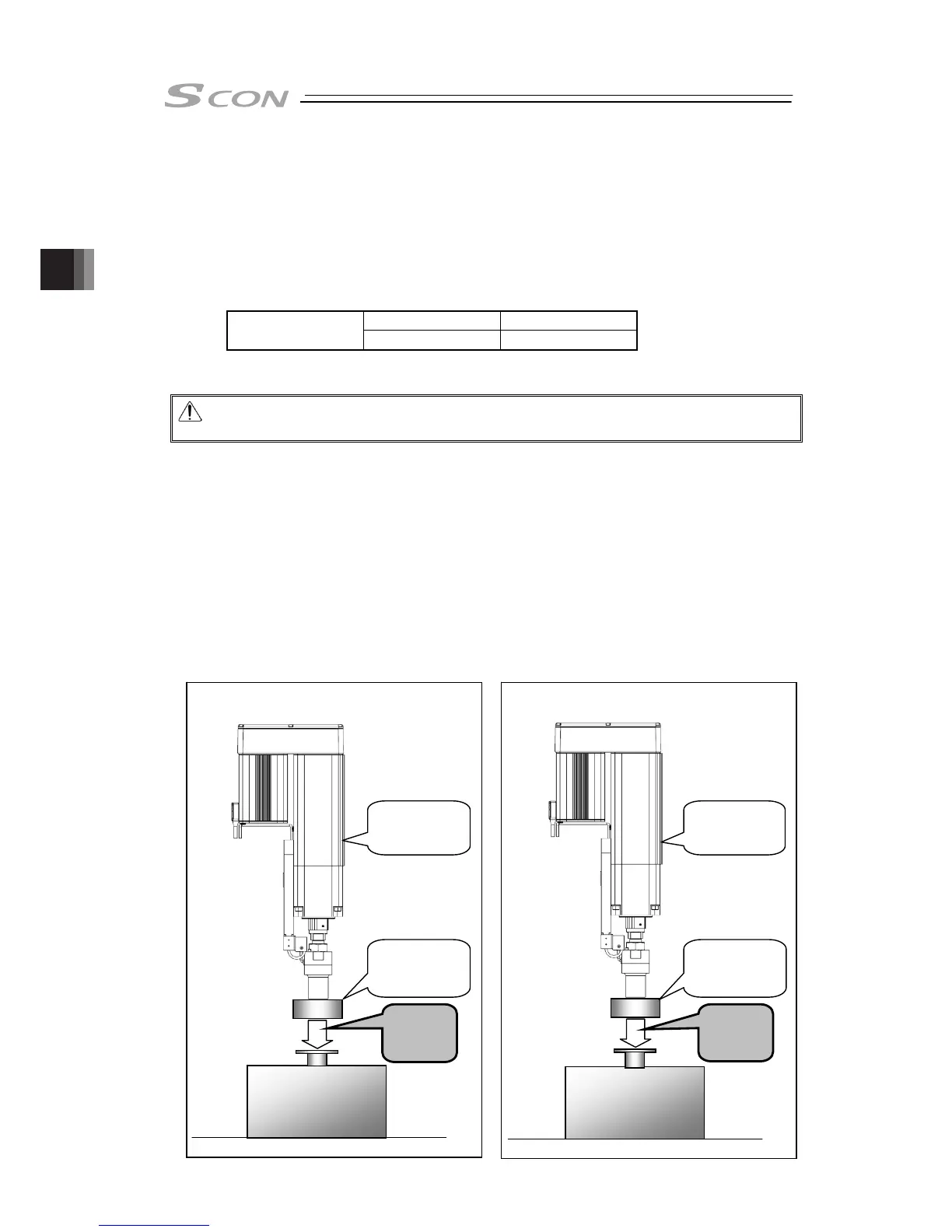

As shown in the figures below, when a pressing operation with 3,000N is desired with a

pressing jig of 1,000N (approx. 100kgf) being attached, and the calibration is not conducted or

the loadcell is not used, the pressing force set in the position table mush be set as it becomes

3,000N – 1,000N = 2,000N. Setting 3,000N in the position table causes pressing force of

4000N to be added to the work.

According to the graph in 10.5.2 RCS2-RA13R Pressing Specifications, if the current limit to

make the pressing force 3,000N is set to the position table, 4,000N of pressing force would be

applied to the work piece.

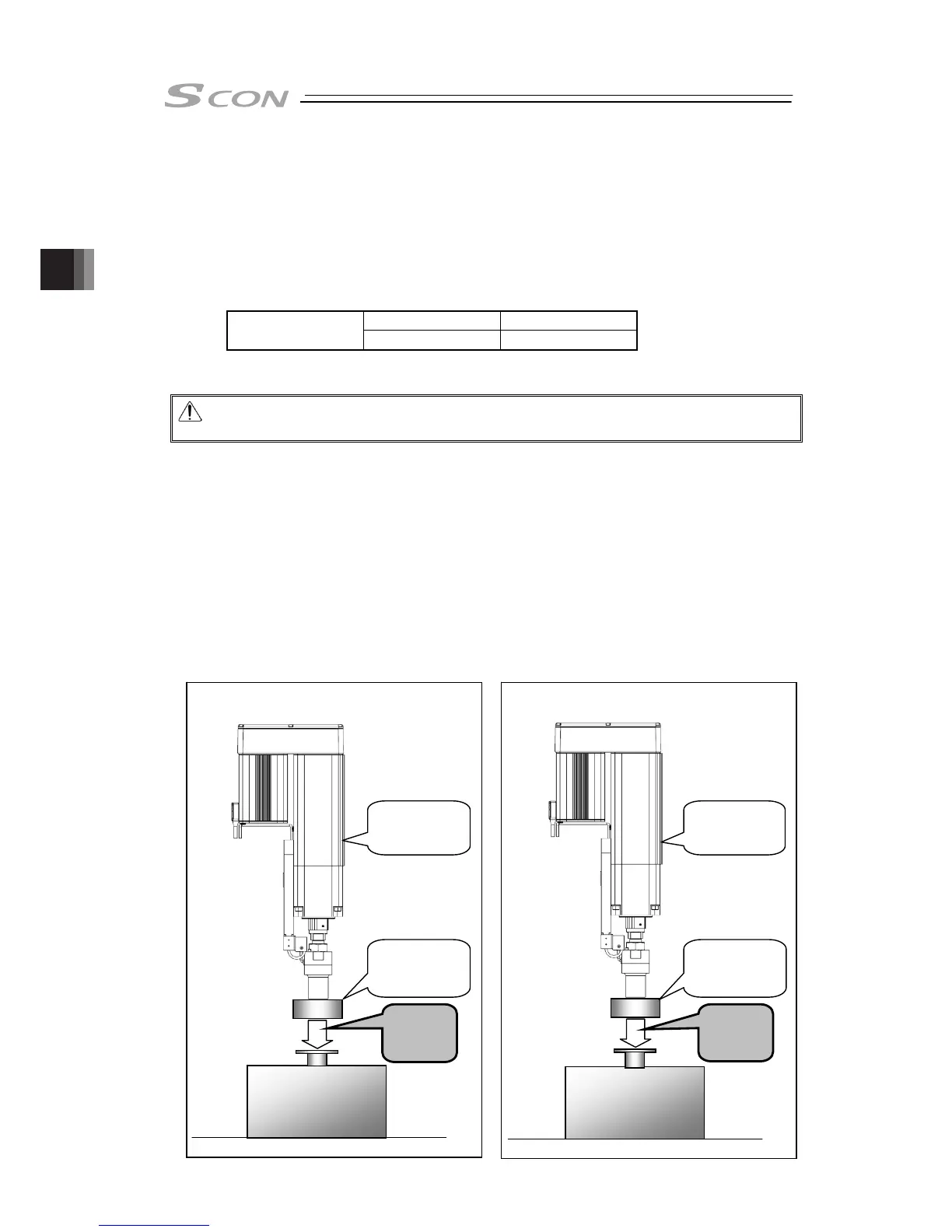

By having a calibration, pressing force setting equivalent to desired 3,000N [current limit %] can

be obtained, which realizes a pressing with high precision.

Calibration enables pressing [%] equivalent to desired pressing force 3,000N to be set in the

position table to realize highly precise pressing force. If the weight of the pressing jig changes,

the value set in the position table may not be changed.

[With calibration disabled] [With calibration enabled]

Set of

pressing force

3

Loading...

Loading...