7. Absolute Reset and Absolute Battery

270

(2) For Teaching Pendant (TB-02/TB-03)

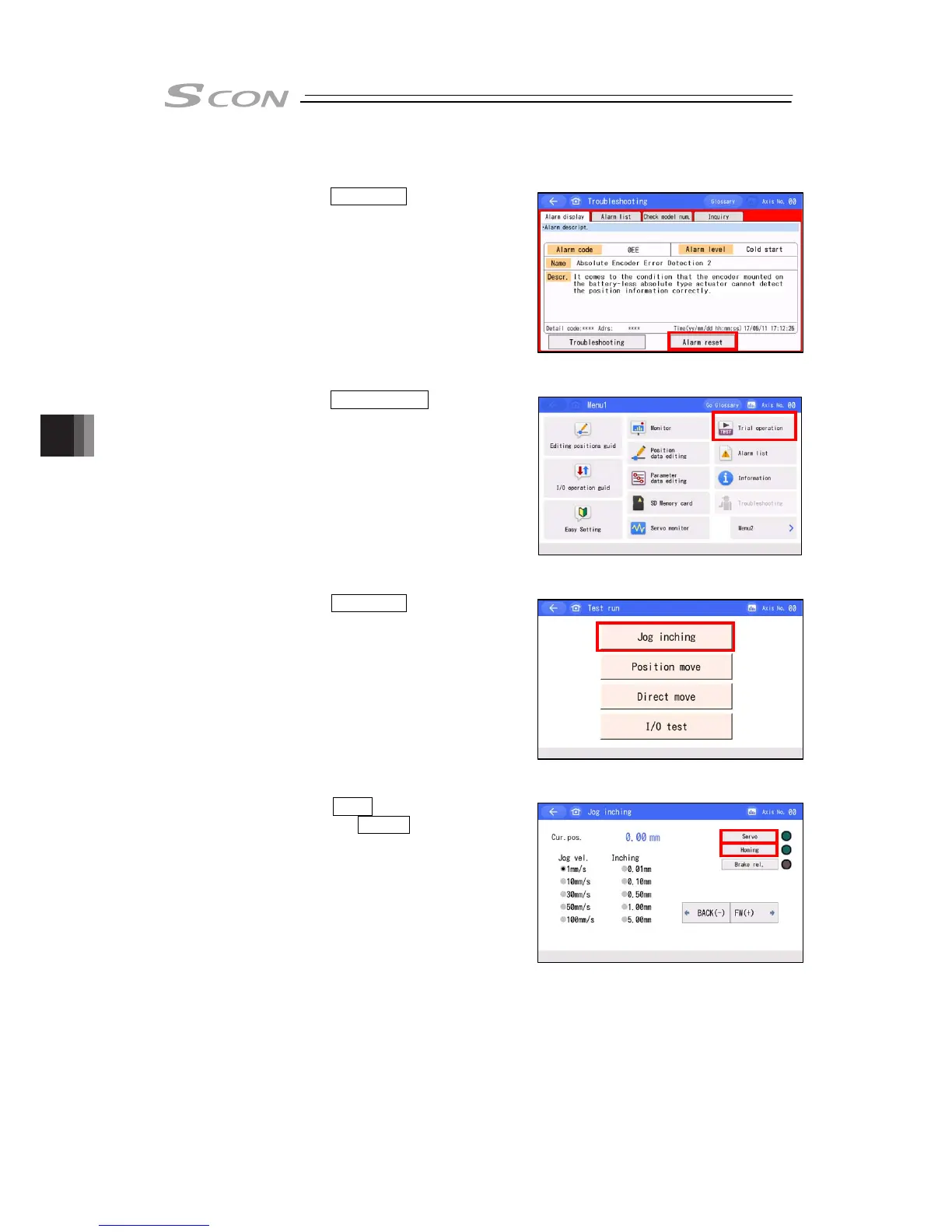

Press Alarm reset.

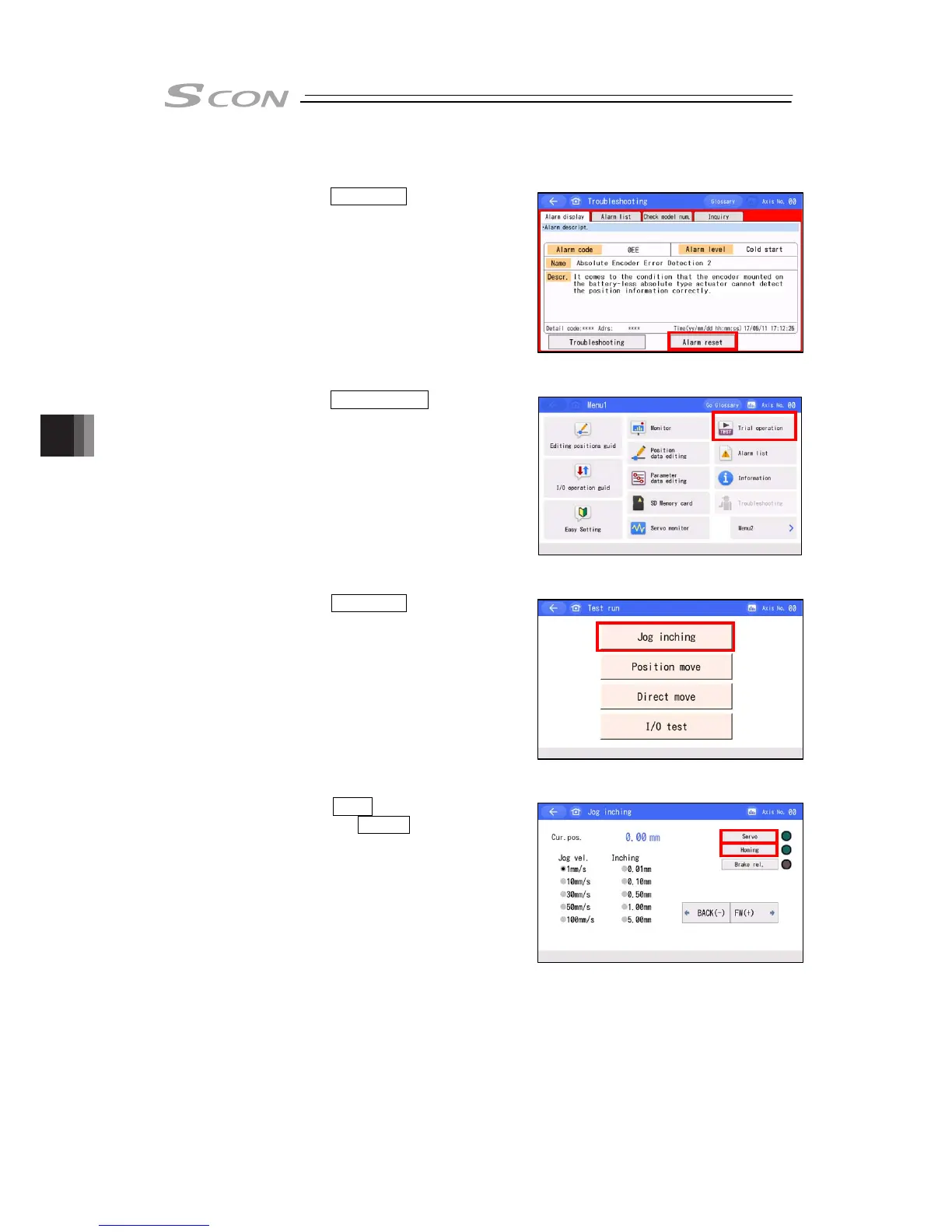

Press Trial Operation on the Menu

1 screen.

Press Jog inching on Test run

screen.

Touch Servo to turn the servo ON

and touch Homing in Jog inching

screen.

1

2

3

4

Loading...

Loading...