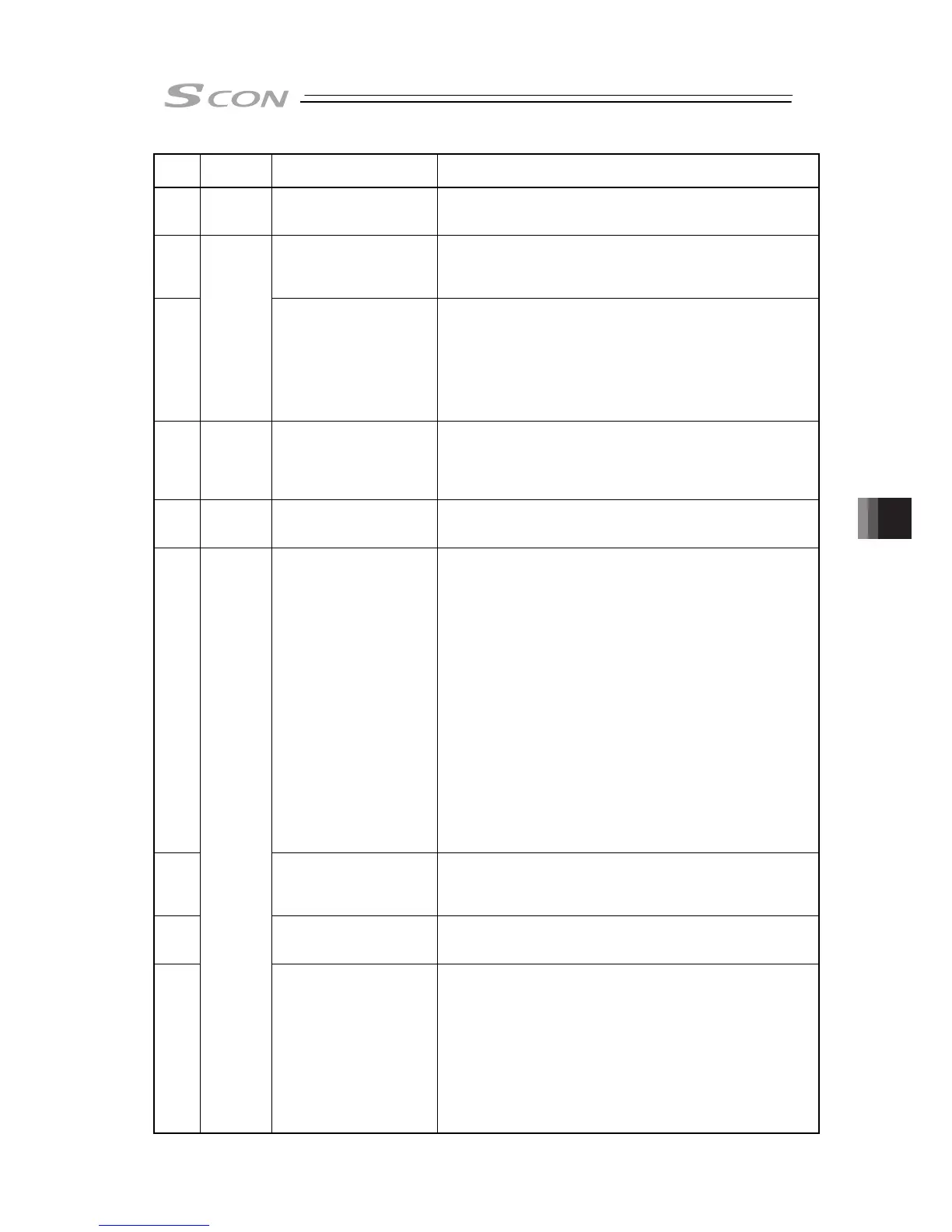

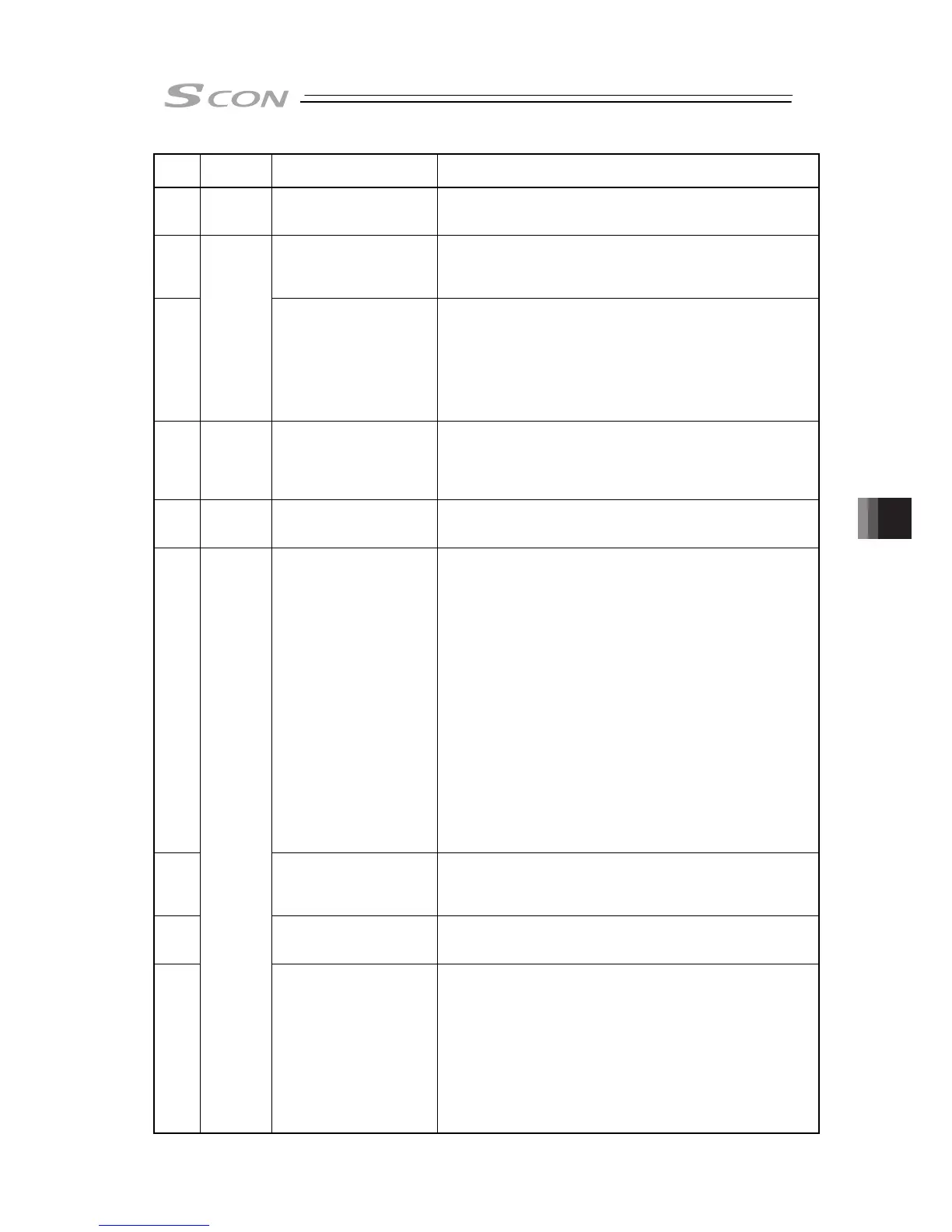

9. Troubleshooting

341

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

0CF

Operation

release

I/O 24V power supply error Cause : 24V power supply for PIO is not connected. The

voltage is extremely low.

Treatment : Check the connection and voltage.

0D2 Motor power source

voltage excessive

Cause : A breakdown of the part inside the controller is

considered.

Treatment : If this error occurs frequently, the controller may be

faulty at high probability. Please contact IAI.

0D3

Cold start

Motor power supply

voltage low

Cause : 1) If the power source is shut off out of the

controller, servo-on command was made during

the power is shut.

2) There is a concern of a malfunction of the

controller internal components.

Treatment : 1) Check the controller external circuit.

2) If this error occurs often, there is a concern of a

controller malfunction. Please contact us.

0D6

Operation

release

FAN error detection Cause : The number of the FAN revolution has dropped to

the alarm level.

Treatment : Check if the FAN is connected properly, and if this

alarm cannot be solved, degradation or malfunction

of the FAN can be considered. Replace the FAN.

0D7 Cold start Belt breaking sensor

detected

Cause : The belt of the ultra-high thrust RCS2-RA13R is

broken.

Treatment : Belt must be replaced. Please contact IAI.

0D8 Deviation overflow Cause : This alarm indicates that the position deviation

counter has overflowed.

1) The speed dropped or the actuator stopped due

to the effect of external force or overload.

2) The excited-phase detection operation following

the power-on is unstable.

3) The power supply voltage dropped.

4) Servo gain number is too small

5) There is a concern of malfunction in controller

component (IPM).

Treatment : 1) This error occurs when the actuator cannot be

operated as it is commanded. Check the load

conditions such as if the work is touching to the

surrounding object, or brake is properly

released, and remove the cause.

2) Overload can be concerned. Revise the

transportable weight and redo the home-return

operation.

3) Check for the source voltage.

5) Replace the controller (PC board).

0D9 Software stroke limit

exceeded

Cause : The current position of the actuator exceeds the

software stroke limit.

Treatment : Return the actuator to be within the range of the

software stroke limit.

0DA Feed back pulse error Cause : Feedback pulse data cannot be output within the

cycle.

Treatment : Take proper measures against noise.

0DC

Operation

release

Pressing motion range

over error

Cause : 1) After the pressing operation has complete, the

force to push back is too large and the pushed

back to the pressing start position (“Position” in

the position table).

2) The actuator touched the work during the

approach movement before the pressing

movement.

Treatment : 1) Revise the setting and adjust it so the force to

push back gets smaller.

2) Set the “Position” setting in front in the position

table to shorten the approach distance.

Loading...

Loading...