5 - 7

Cygnus 2 Operating Manual

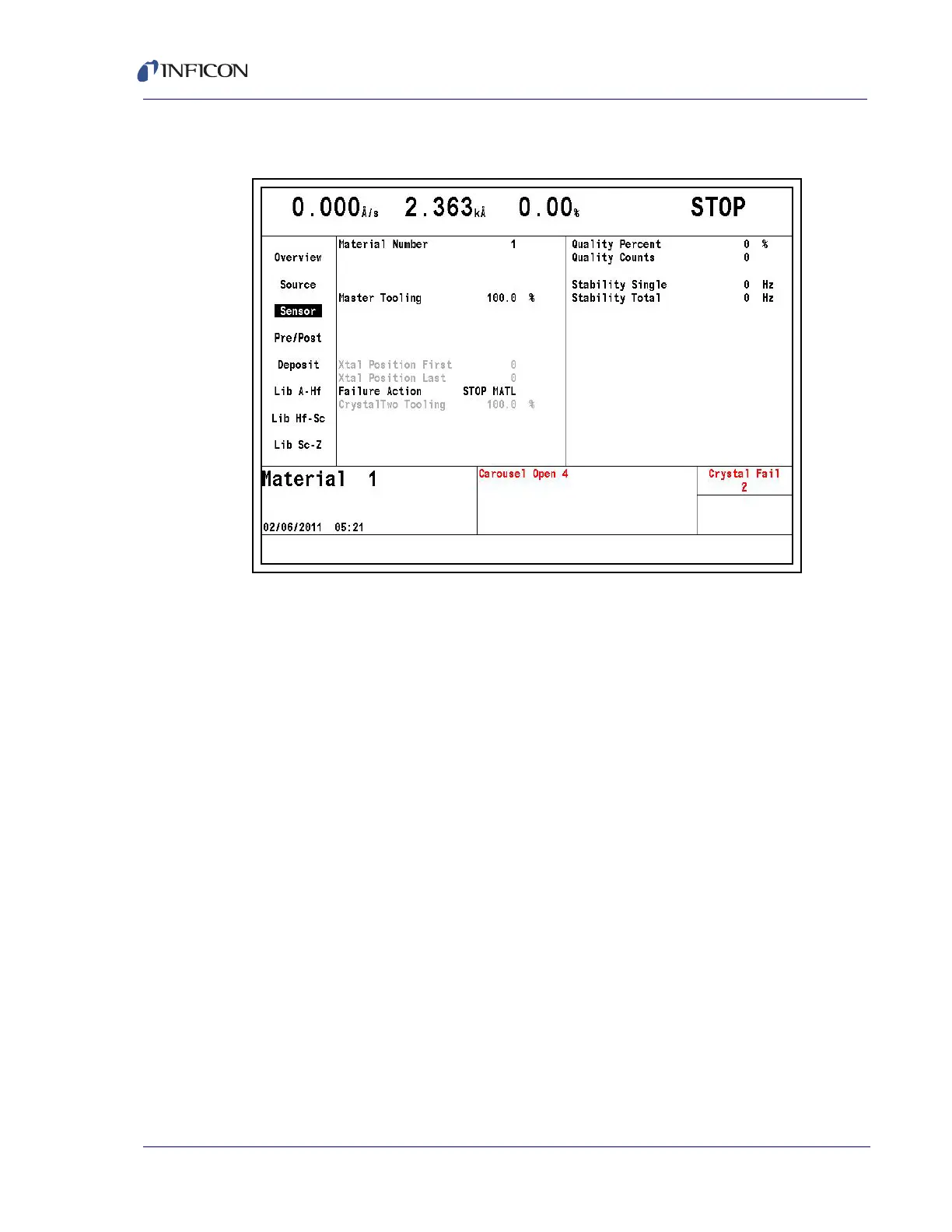

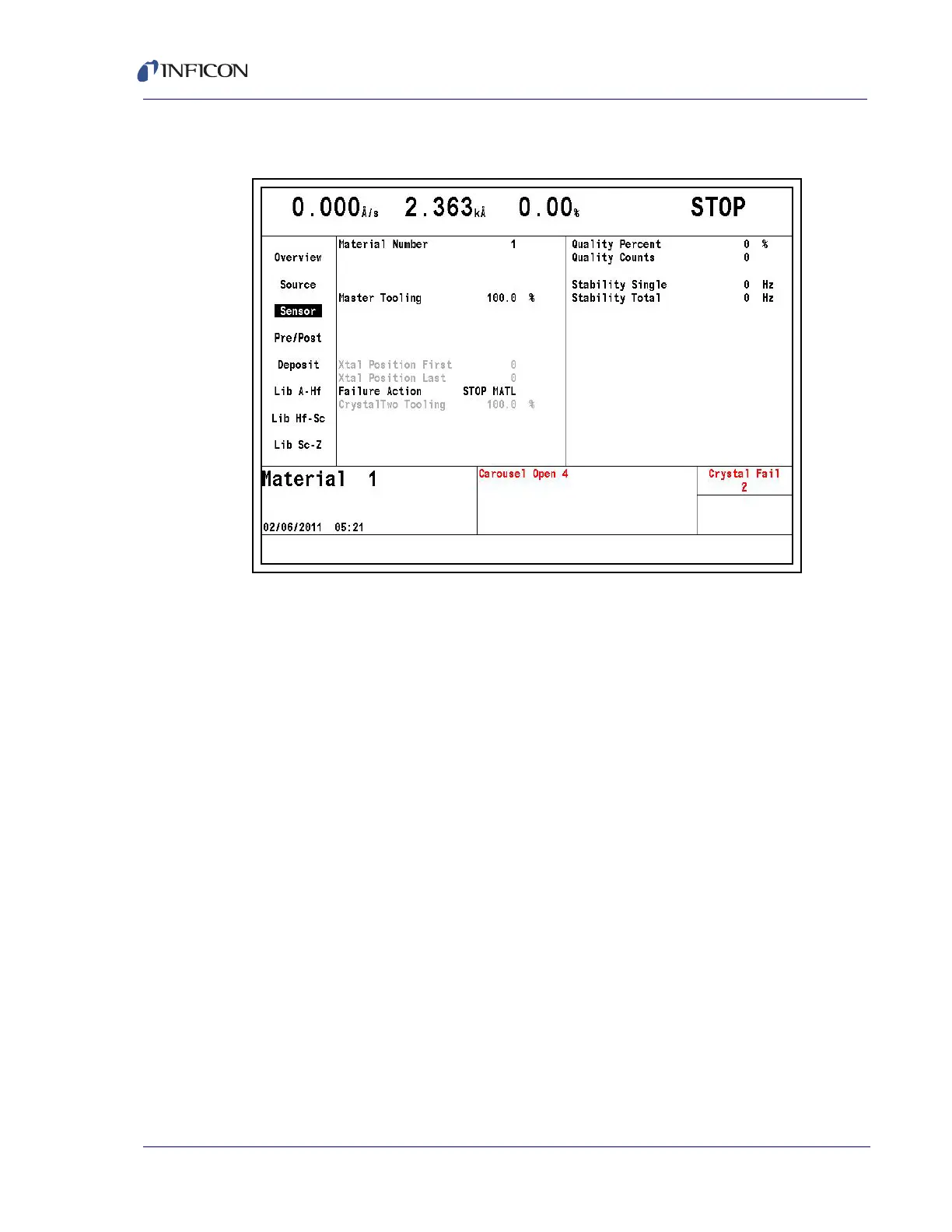

5.1.4 Material Sensor Parameters Page

Figure 5-6 Material sensor page

MATERIAL NUMBER . . . . . . . . . . . 1 to 6

Change the number to edit or create a different Material.

MASTER TOOLING. . . . . . . . . . . . . 1.0 to 999.9%

Tooling is a correction factor used for correlating the rate and thickness

accumulation on the crystal with the thickness accumulation on the substrate.

This thickness difference is due to the geometric distribution of material flux

from the source.

The MASTER TOOLING factor is calculated using equation [1].

[1]

where TF

i

= Initial Tooling Factor, T

m

= Actual Thickness at the

Substrate, and T

x

= Thickness on the Crystal.

The default value is 100%.

If the TOOLING is changed, the new TOOLING value is used for subsequent

calculation of the individual as well as aggregate rate and thickness. Also, the

thickness accumulated thus far will be re-scaled based on the change to the

TOOLING.

Loading...

Loading...