Appendix B

-

145

-

B.2 Modbus Communication Protocol

The drive provides RS485 communication interface and supports Modbus-RTU communication protocol, so

that the user can implement centralized control, such as setting running commands and function codes, and

reading running status and fault information of the AC drive, by using a PC or PLC.

This protocol denes content and format of transmitted messages during serial communication, including mas-

ter polling (or broadcasting) format and master coding method (function code for the action, transmission data,

and error check). The slave uses the same structure in response, including action conrmation, data returning

and error check. If an error occurs when the slave receives a message, or the slave cannot complete the action

required by the master, the slave returns a fault message as a response to the master.

B.2.1 Application

The AC drive is connected to a "single-master multi-slave" PC/PLC control network with RS485 bus.

B.2.2 Bus Structure

1. Interface mode

The RS485 extension card MD38TX1 must be inserted into the AC drive.

2. Topological structure

The system consists of a single master and multiple slaves. In the network, each communication device has a

unique slave address. A device is the master (can be a PC, a PLC or an HMI) and initiates communication to

perform parameter read or write operations on slaves. The other devices (slaves) provide data to respond to

query or operations from the master. At the same moment, either the master or the slave transmits data and

the other can only receives data.

The address range of the slaves is 1 to 247, and 0 is broadcast address. A slave address must be unique in the

network.

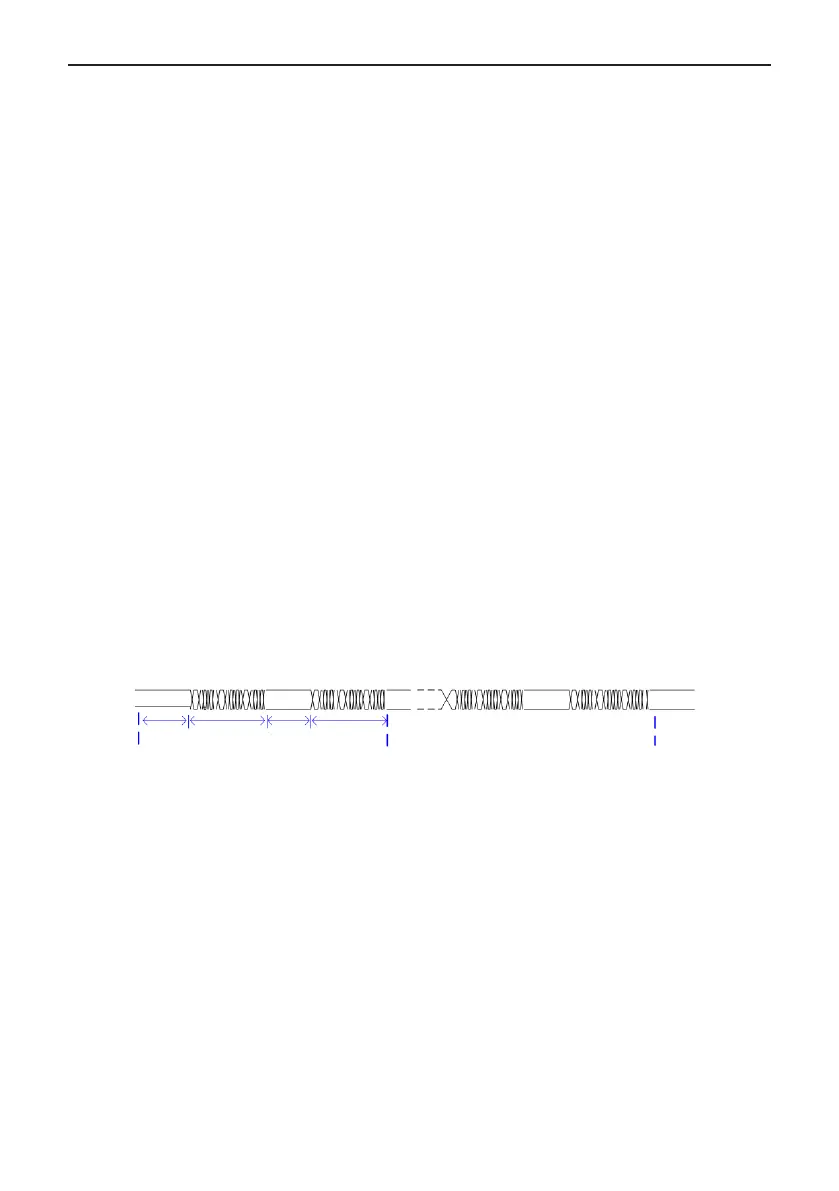

3. Transmission mode

The asynchronous serial and half-duplex transmission mode is used. During asynchronous serial communica-

tion, data is sent frame by frame in the form of message. In Modbus-RTU protocol, an interval of at least 3.5-byte

time marks the end of the previous message. A new message starts to be sent after this interval.

Master sending 1 Slave response 1 Master sending 2 Slave response

2

Interval of at

least 3.5-byte

time

Interval of at

least 3.5-byte

time

Data frame

Data frame

A

B

The communication protocol used by the drive is the Modbus-RTU slave communication protocol, which allows

the drive to provide data to respond to "query/command" from the master or execute the action according to

"query/command" from the master.

The master can be a PC, an industrial device, or a PLC. The master can communicate with a single slave or

send broadcast messages to all slaves. When the master communicates with a single slave, the slave needs to

return a message (response) to "query/command" from the master. For a broadcast message sent by the mas-

ter, the slaves need not return a response.