5 Basic Operations and Trial Run

-

71

-

5

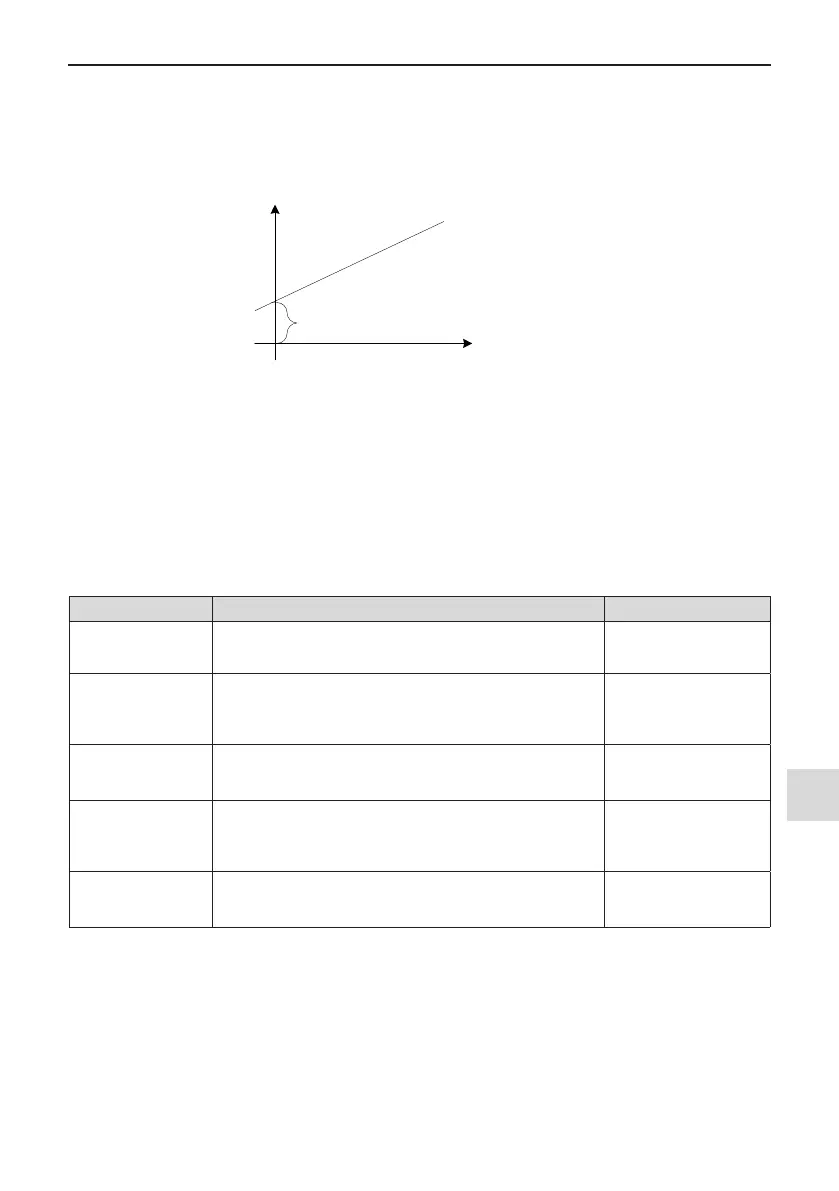

These four function parameters can dene required AO curve.

If "b" represents zero offset, "k" represents gain, "Y" represents actual output of the AO, and "X" represents

output frequency, then the actual output is

Y=kX + b.

b=F5-10

k

=F5-11

Parameter to be

output (X before

correction)

AO1 output

(Y after correction)

Figure 5-12 AO signal correction characteristic curve

Zero offset coefcient 100% of AO1 and AO2 corresponds to 10 V or 20 mA. A standard output is the value cor-

responding to 0 to 10 V or 0 to 20 mA without offset or gain.

For example, AO is used for output of frequency reference. To implement output of 8 V at 0 Hz and output of 4

V at 40 Hz, set F5-11 to -0.5 and set F5-10 to 80%.

5.10 Auto-tuning

You can obtain parameters of controlled motor through motor auto-tuning. Motor auto-tuning methods are dy-

namic auto-tuning, static auto-tuning 1, and static auto-tuning 2. You can enter the motor parameters manually.

Auto-tuning Method Application Result

Dynamic auto-tuning

with no-load

F1-37 = 2

It is applied to applications where motor can be disconnected from

load.

Best

Dynamic auto-tuning

with load

F1-37 = 2

It is applied to applications where motor cannot be disconnected

from load and dynamic auto-tuning is not allowed. The load friction

force is small and the motor is appropriately idle when running at

a constant speed.

The effect is better with

smaller friction force.

Static auto-tuning 1

F1-37 = 1

It is applied to applications where the motor cannot be

disconnected from the load and dynamic auto-tuning is not

allowed.

OK

Static auto-tuning 2

F1-37 = 3

It is applied to applications where the motor cannot be

disconnected from the load and dynamic auto-tuning is not

allowed. This mode is recommended for static auto-tuning. It

lengthens the auto-tuning time compared to static auto-tuning 1.

Better

Manual parameter

input

It is applied to applications where the motor cannot be

disconnected from the load. Copy parameters of motors of same

model which have been auto-tuned to F1-00 to F1-10.

Better