Chapter 10 — Adjustments

EasyCoder PF4i User’s Guide (IPL Version) 101

Adjusting the Label Stop Sensor

The label stop sensor (LSS) is a photoelectric sensor that controls

the printer’s media feed by detecting gaps between labels or slots

or black marks in continuous stock, depending on the printer’s

setup in regard of media type. The LSS should be aligned with

the gaps, slots, or black marks. If using irregularly shaped labels,

align the LSS with the front tips of the labels.

The LSS can be moved laterally between 5 fi xed positions. There

is one part of the sensor on top of the upper media guide and

another part underneath the lower guide. These must be adjusted

individually to the same position. Using a small screwdriver, push

them inwards as far as they go and then pull them out one at the

time while counting the clicks from the snap-locks. A hole in the

bottom plate facilitates adjustment of the lower sensor package.

The various detection points of the sensor in relation to the inner

edge of the media are as follows:

One click out 3 mm / 0.118 inch

Two clicks out 8 mm / 0.315 inch

Three clicks out 12 mm / 0.472 inch

Four clicks out 16 mm / 0.639 inch

Five clicks out 20 mm / 0.787 inch

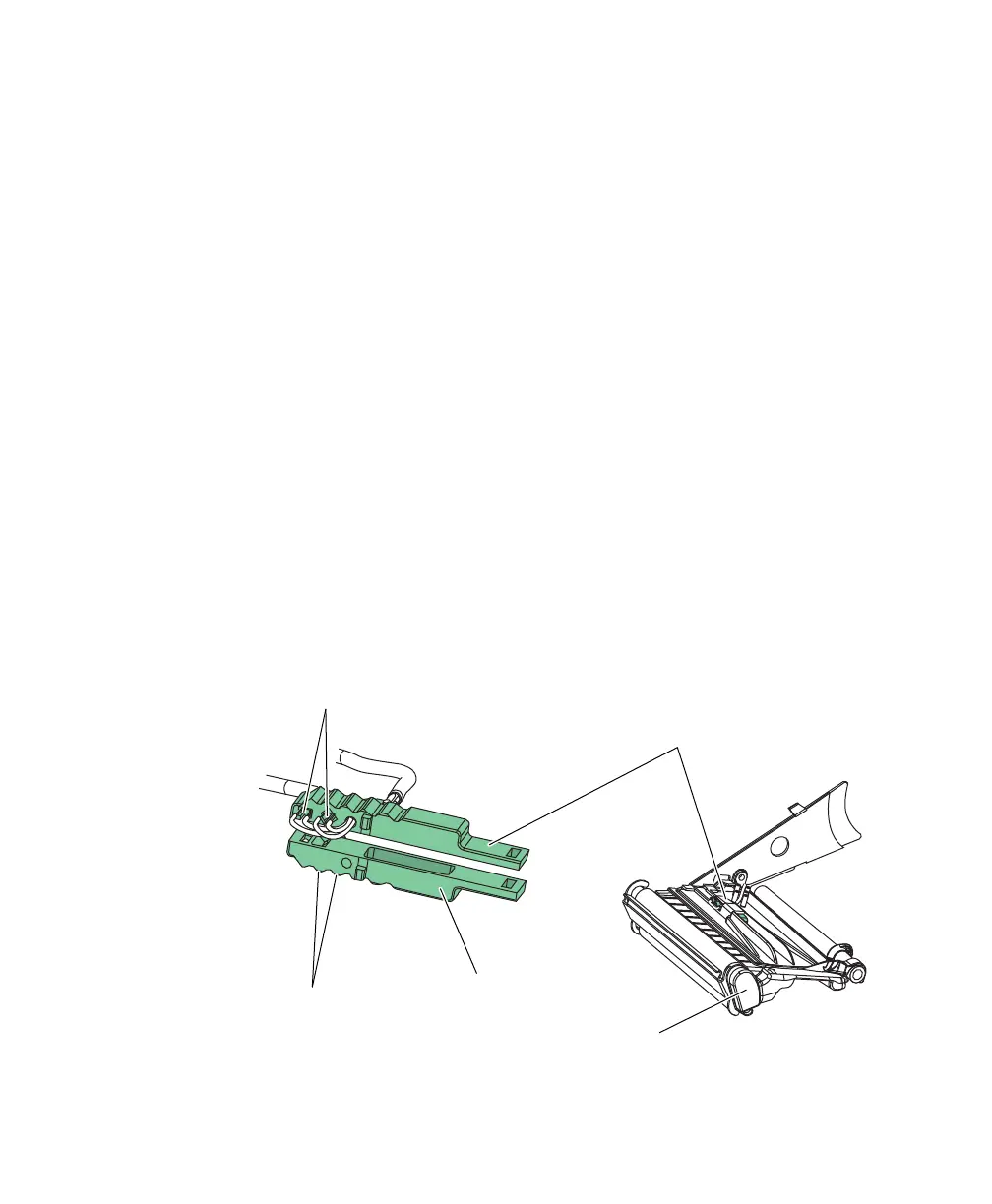

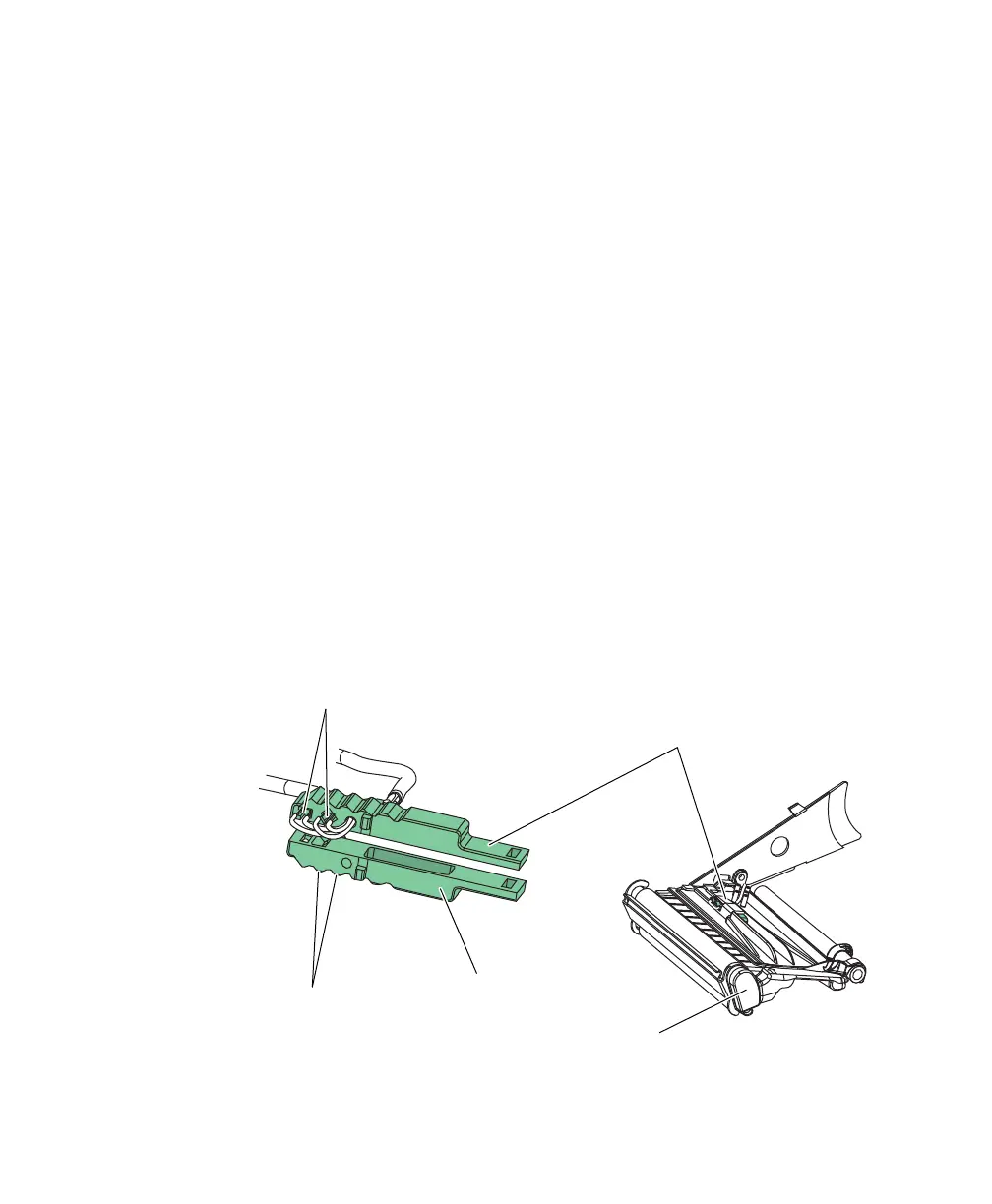

Label Stop Sensor Parts and Location

One diode +

One sensor

One diode +

One sensor

Lower part of LSS

Upper part of LSS

Print mechanism

Loading...

Loading...