4.15.1

Manual traverse/rotate operation (t)

Z

In manual traverse/rotate operation the fork

carriage rotates as the attachment is

moving.

Requirements

– Prepare the truck for operation, see

page 138 or see page 139.

Procedure

• Do not press the dead man's switch (20).

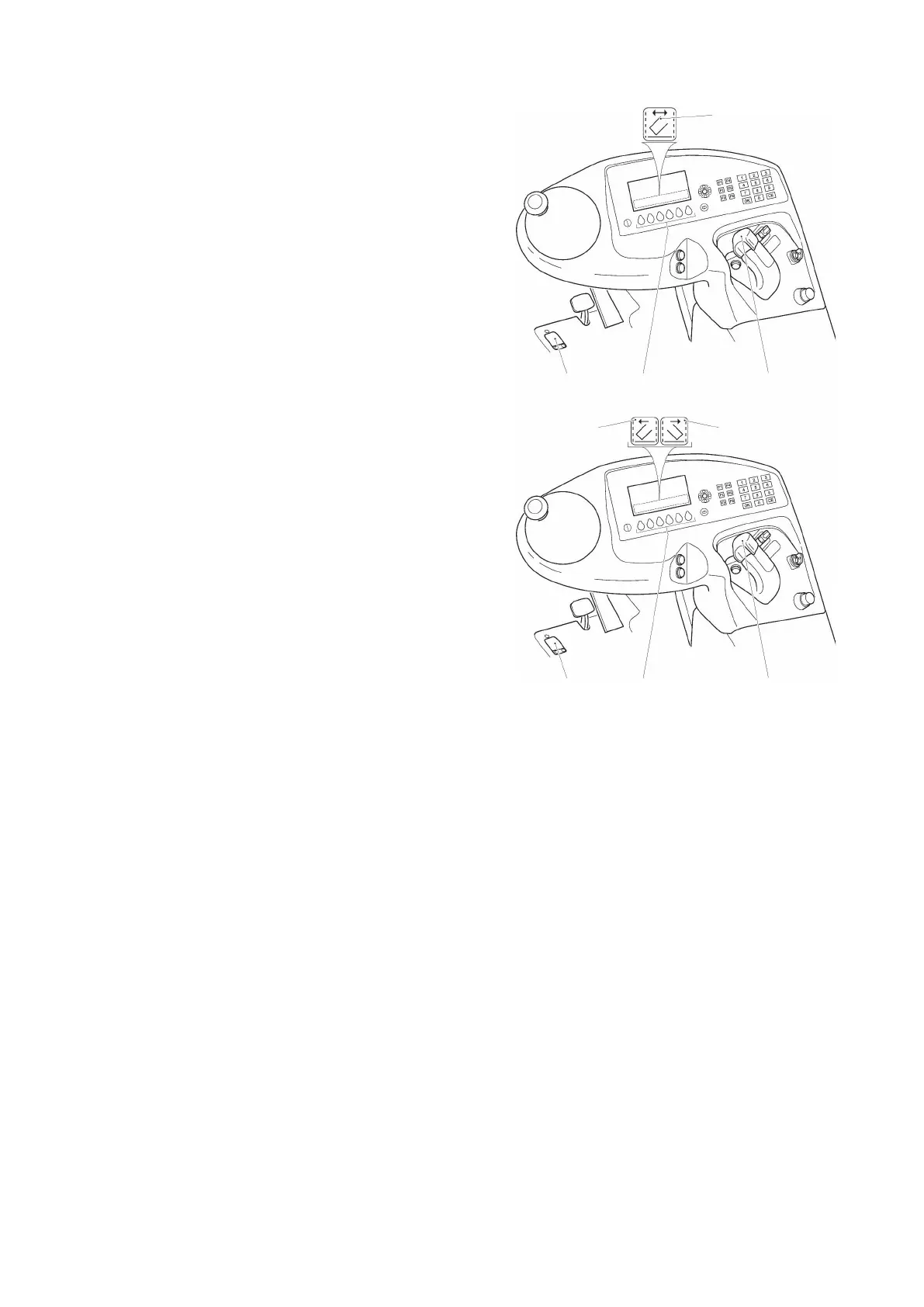

• Press the key (104) under the

"synchronised rotate menu change"

symbol (173).

The display changes from the menu item

“synchronised rotation menu

change” (173) to "synchronised fork

rotation to the right " (175) or

"synchronised fork rotation to the

left" (174).

Z

The rotation speed cannot be changed.

The traverse speed is proportional to how

far the "hydraulics function" control

lever (113) is moved. Manual traverse/

rotate operation can be cancelled by

releasing the (104) key or the "hydraulic

functions" control lever (113). The

attachment must then be moved manually

to the home position.

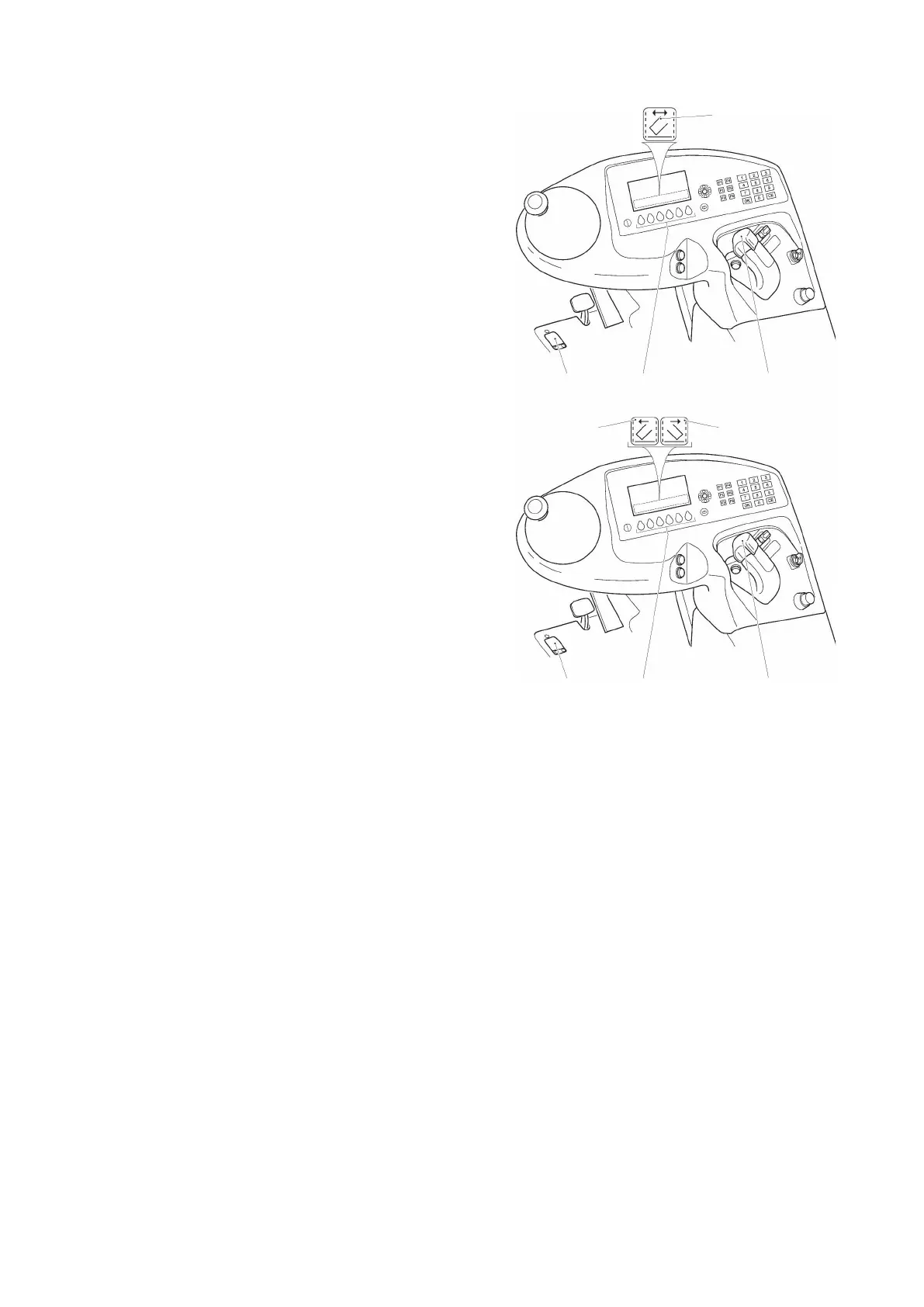

• Synchronised fork carriage rotation to the

right and load handler traverse to the left:

• Press and hold down the key (104)

under the "synchronised fork rotation to

the right" symbol (175).

• Turn the "hydraulic functions" control

lever (113) anticlockwise until the home

position has been reached.

• Synchronised fork carriage rotation to the

left and load handler traverse to the right:

• Press and hold down the key (104)

under the "synchronised fork rotation to

the left " symbol (174).

• Turn the "hydraulic functions" control

lever (113) clockwise until the home

position has been reached.

The attachment is located at the right or left

mechanical limit position of the swivel

traverse frame and the forks are rotated

through 180°.

183

04.19 en-GB

Loading...

Loading...