8 Optional equipment

8.1

Sideshifter / Fork positioner (o)

WARNING!

A faulty attachment can be hazardous

Check the attachment daily for external signs of damage or defects. Faulty

attachments can cause the load to fall.

u

Report any defects immediately to your supervisor.

u

Tag out and decommission a faulty lift truck.

u

Only return the truck to service when you have identified and rectified the fault.

Z

Maintenance intervals are specified in the section Maintenance, Inspection and

Changing of Maintenance Parts Requiring Replacement, see page 357.

8.1.1

Fork sideshift (o)

Requirements

– Prepare the truck for operation, see page 138 or see page 139.

Procedure

• Do not press the dead man's switch (20).

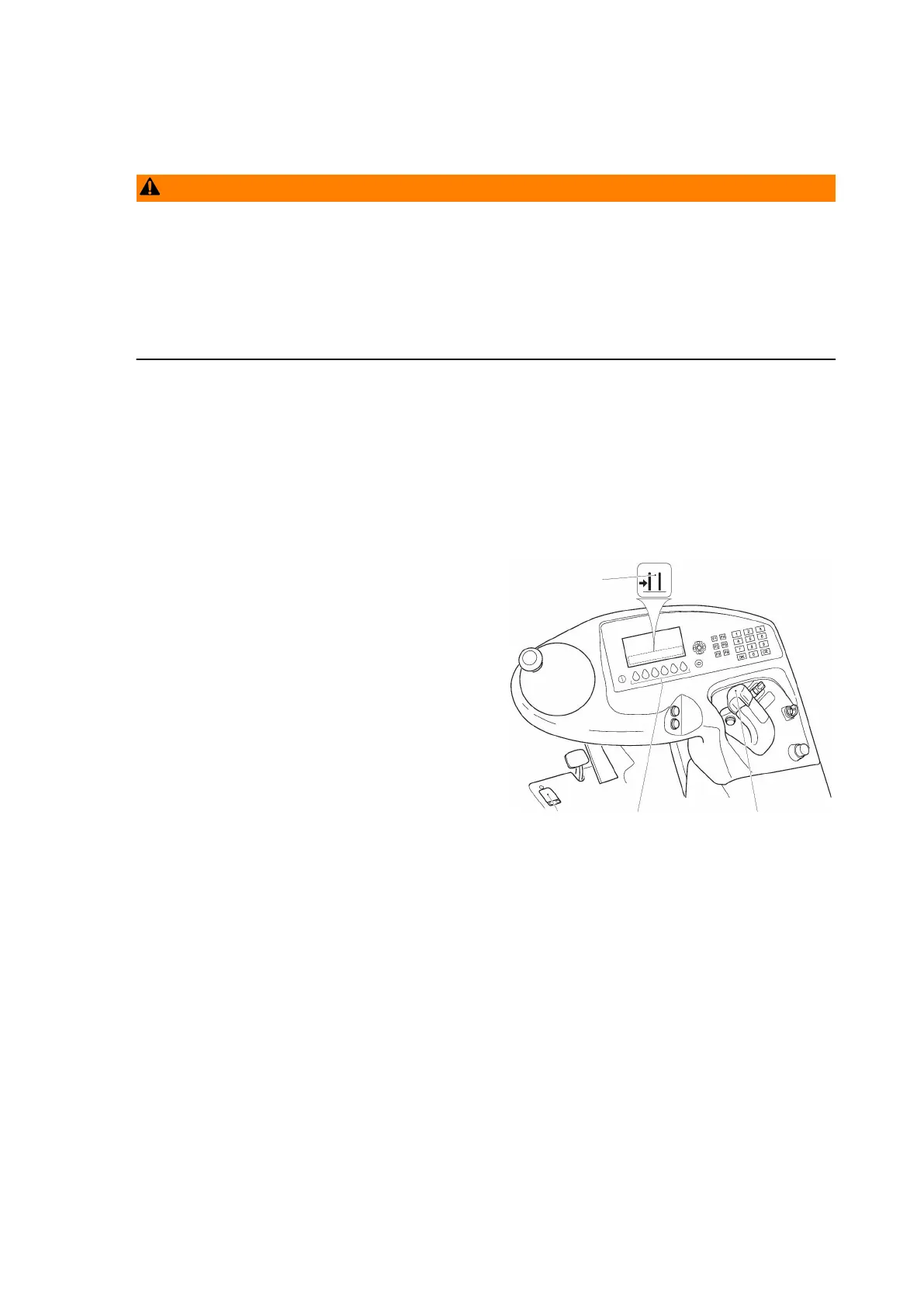

• Press and hold down the key (104)

under the "fork sideshift" symbol (194).

• Attachment is in the "front lift" position,

i. e. the forks are at right angles to the

swivel traverse frame:

• To shift the forks to the right:

Turn the "hydraulic functions" control

lever (113) clockwise.

• To shift the forks to the left:

Turn the "hydraulic functions" control

lever (113) anticlockwise.

• Attachment is in the right-hand home position, i. e. the fork carriage is at the right

end of the swivel traverse frame and the forks are facing left:

• To shift the forks in the load direction:

Turn the "hydraulic functions" control lever (113) clockwise.

• To shift the forks in the drive direction:

Turn the "hydraulic functions" control lever (113) anticlockwise.

• Attachment is in the left-hand home position, i. e. the fork carriage is at the left

end of the swivel traverse frame and the forks are facing right:

• To shift the forks in the drive direction:

Turn the "hydraulic functions" control lever (113) clockwise.

• To shift the forks in the load direction:

Turn the "hydraulic functions" control lever (113) anticlockwise.

Z

The traverse speed of the forks is proportional to the movement of the "hydraulic

functions" control lever (113).

Both forks move evenly in the prescribed direction.

247

04.19 en-GB

Loading...

Loading...