8.1.2

Fork positioner (o)

WARNING!

Trapping hazard and risk of material damage when adjusting the forks

Other people can be damaged when the forks are adjusted.

Apart from the operator (in the normal operating position) there should be no other

people in the truck's hazardous area.

u

Instruct other people to move out of the hazardous area of the truck. Stop working

with the truck if people do not leave the hazardous area.

u

If people do not leave the hazardous area despite the warning, prevent the truck

from being used by unauthorised people.

u

The fork spread must only be adjusted without load.

Requirements

– Prepare the truck for operation, see page 138 or see page 139.

Procedure

Z

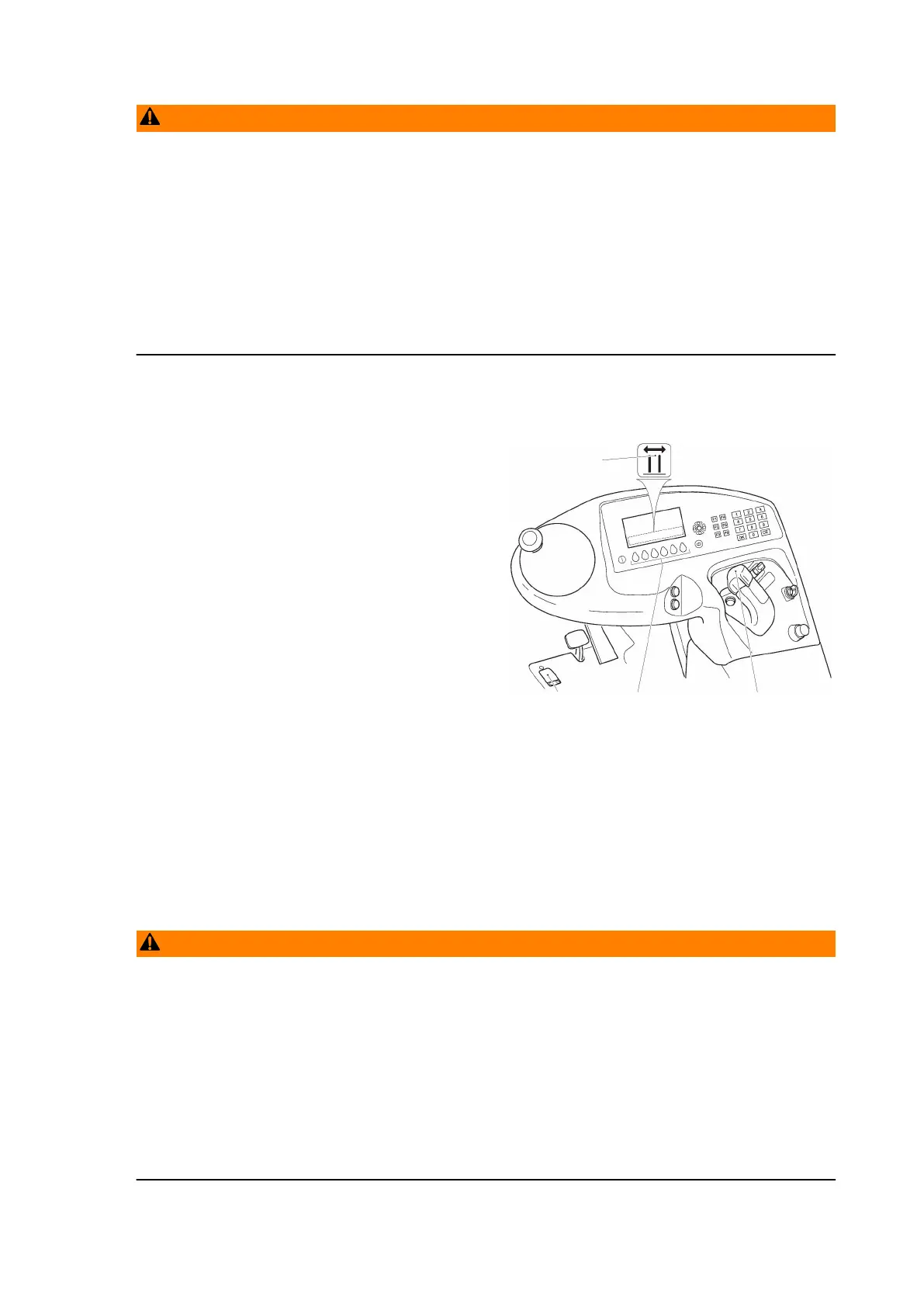

The fork spread is changed when the

two forks traverse simultaneously. The

forks cannot be adjusted individually.

• Do not press the deadman button (20).

• Press and hold down on the button (104)

under the "Fork adjustment"

symbol (195).

• To reduce the fork spread:

• Turn the "Hydraulic functions" control

lever (113) clockwise.

• To increase the fork spread:

• Turn the "Hydraulic functions" control lever (113) anti-clockwise.

Z

The traverse speed of the fork spread is in proportion to the movement of the

"Hydraulic functions" control lever (113).

The fork spread is reduced or increased.

8.1.3

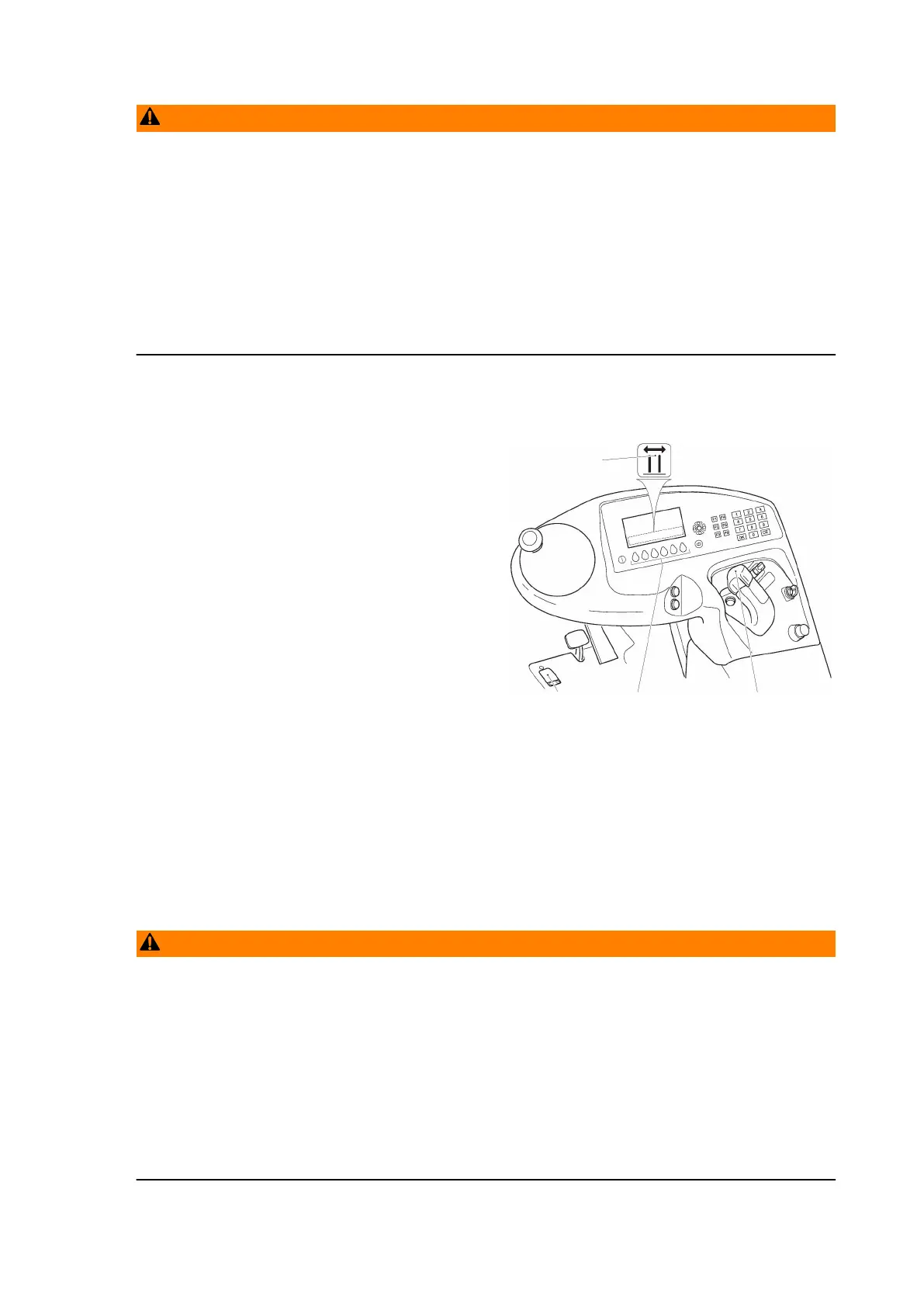

Symmetric sideshift with integrated fork positioner (o)

WARNING!

Trapping hazard and risk of material damage when adjusting the forks

Other people can be damaged when the forks are adjusted.

Apart from the operator (in the normal operating position) there should be no other

people in the truck's hazardous area.

u

Instruct other people to move out of the hazardous area of the truck. Stop working

with the truck if people do not leave the hazardous area.

u

If people do not leave the hazardous area despite the warning, prevent the truck

from being used by unauthorised people.

u

The fork spread must only be adjusted without load.

249

04.19 en-GB

Loading...

Loading...