Installation

06-237619-001 4-19 April 2020

4-6.8 Installing Slave Cylinder Gauge Assembly

Follow these steps to install the slave cylinder gauge assembly:

1. Make sure the O-ring in the connecting swivel of the slave cylinder gauge assembly is in

place and properly lubricated. If lubrication is missing, use silicone spray (Würth Art no:

0893221 or similar).

2. Installing slave cylinder gauge assemblies as indicated on the bank assembly drawing. Ap-

ply a torque of 33.2 ± 0.75 ft lbf (45 ± 1N-m). A counter hold may be required.

3. Leak test all connections on the slave cylinder gauge assembly by means of ammonium-

free leak detection liquid or spray, ensuring that there is no leakage.

Note: The pre-assembled unit shall not be tampered with, as any adjustment to components

pre-fitted to the connector block will lead to a leak.

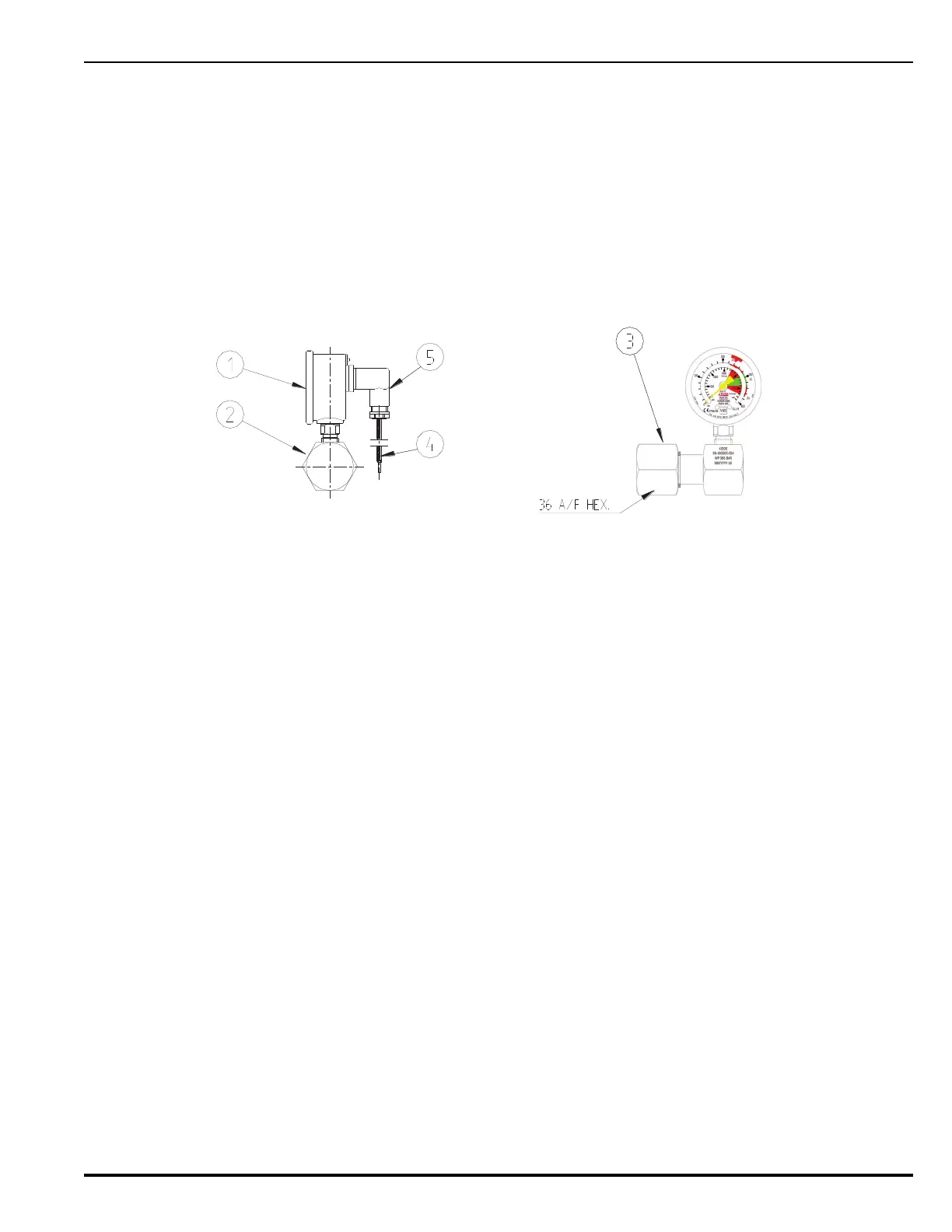

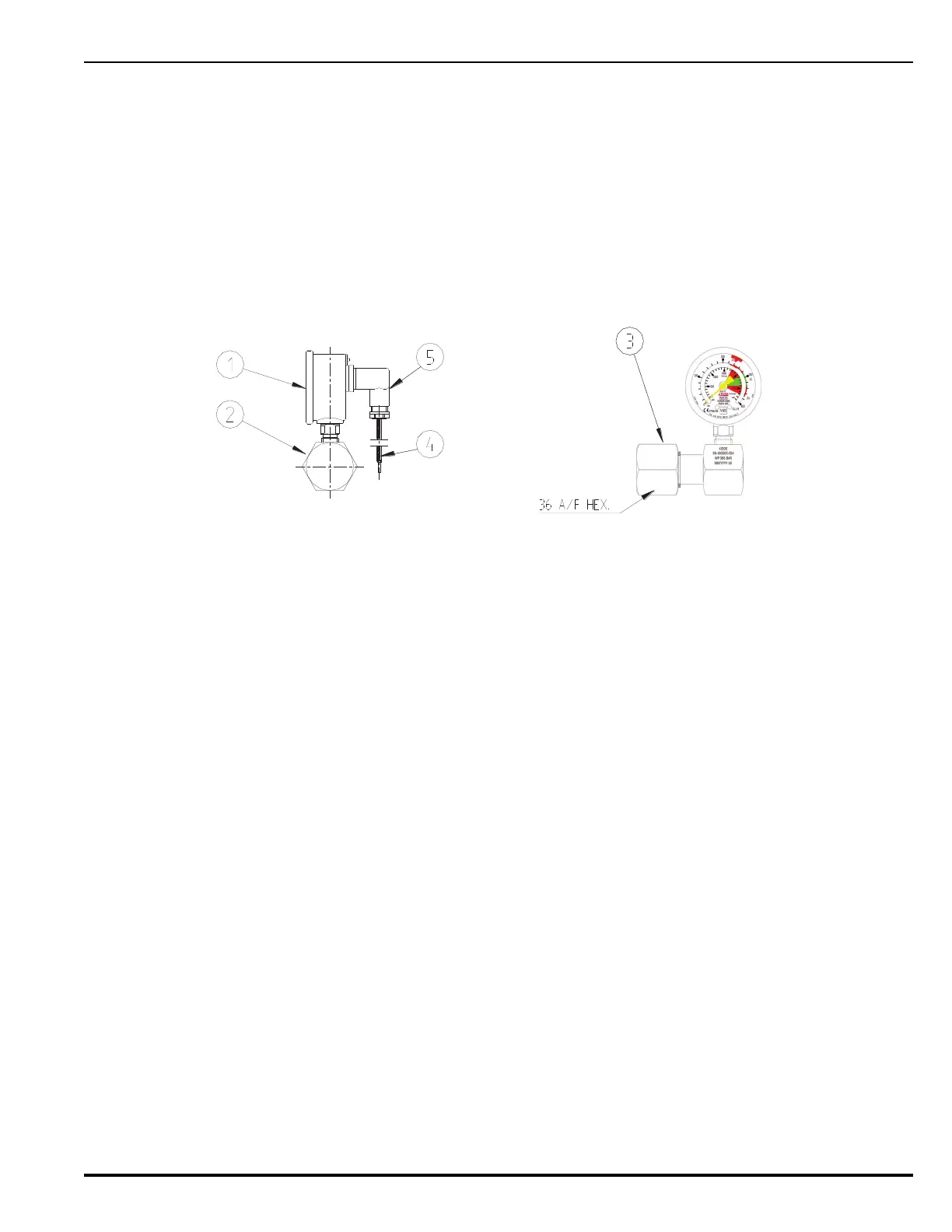

Figure 4-17. Contacts for Pressure Gauge

Key:

(1) Contact pressure gauge (2) Connection block (3) Connecting swivel

(4) two core cable with quick connect cable joiner

(5)

Connector for contact gauge

Loading...

Loading...