Installation

06-237619-001 4-25 April 2020

4-8.3 Fittings

Fittings shall conform to the requirements of NFPA 2001, 2015 Edition, Sections 2-2.3 and A-

2-2.3.1. Class 150 and cast iron fittings must not be used. Class 400 lb malleable or ductile

iron fittings in sizes 3-inch and smaller, or 1000 lb ductile iron or forged steel fittings in sizes

greater than 3-inch are to be used. Class 400 flanged joints are acceptable for use in all sizes.

Alternately, forged steel fittings can be used.

Note: Systems installed in Europe should not use malleable fittings unless approved by the

local AHJ.

Concentric bell reducers are the only means for reducing pipe size under NFPA guidelines. For

European systems, reducing bushes may be used. Reductions can be made after a tee or after

a union. Where reducers are used at tees, the reducers must be downstream of each tee.

Reductions made after a union are possible only if the next change in direction (tee split) is

located a minimum of 10 nominal pipe diameters downstream of the concentric bell reducer.

Gaskets for flanged fittings shall be neoprene impregnated or compliant with NFPA 2001,

Edition 2015.

Fittings shall be used with a working pressure of not less than 70 bar i.e. EN 10241 (Seamless

with test pressure of 150 bar) or BS 3799 (3000 lb) forged steel.

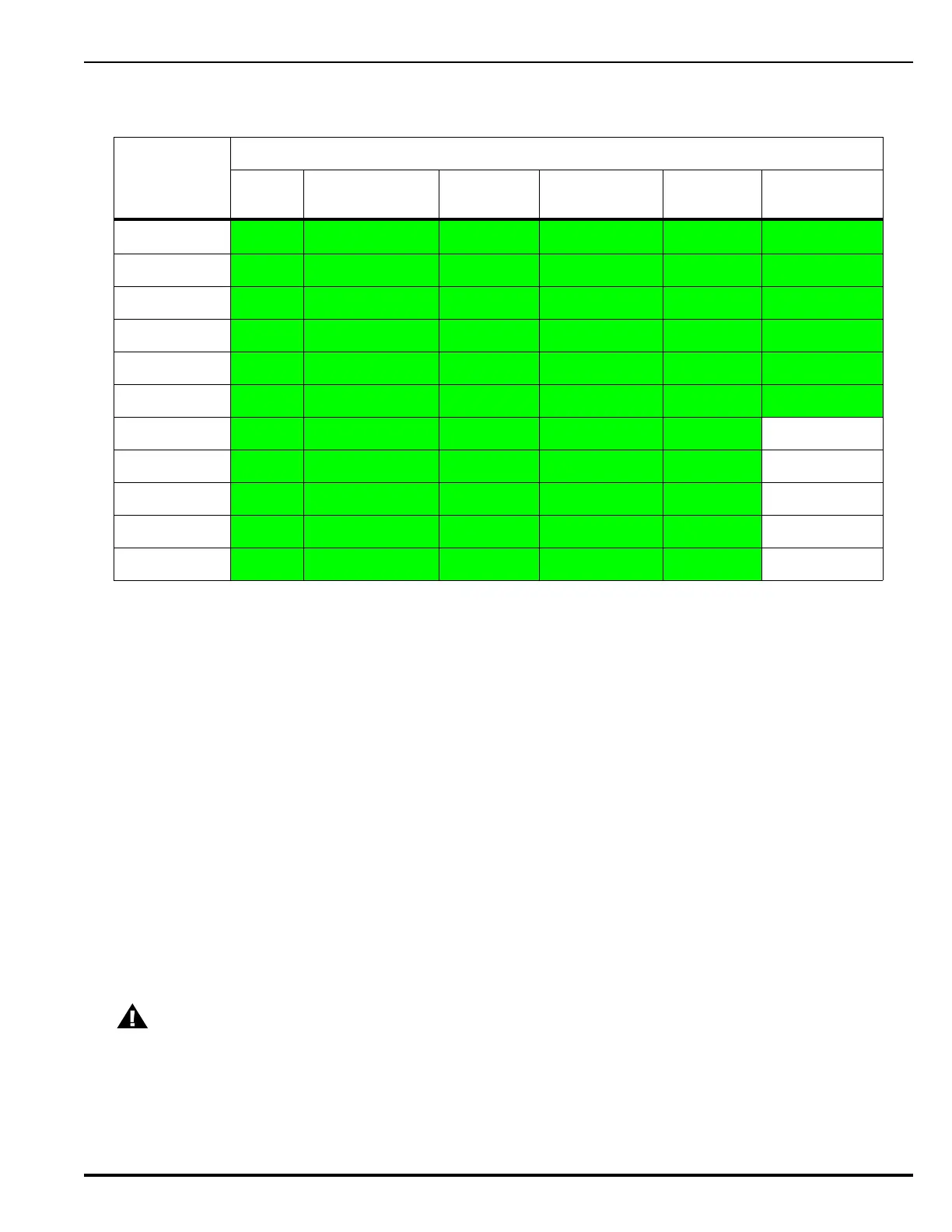

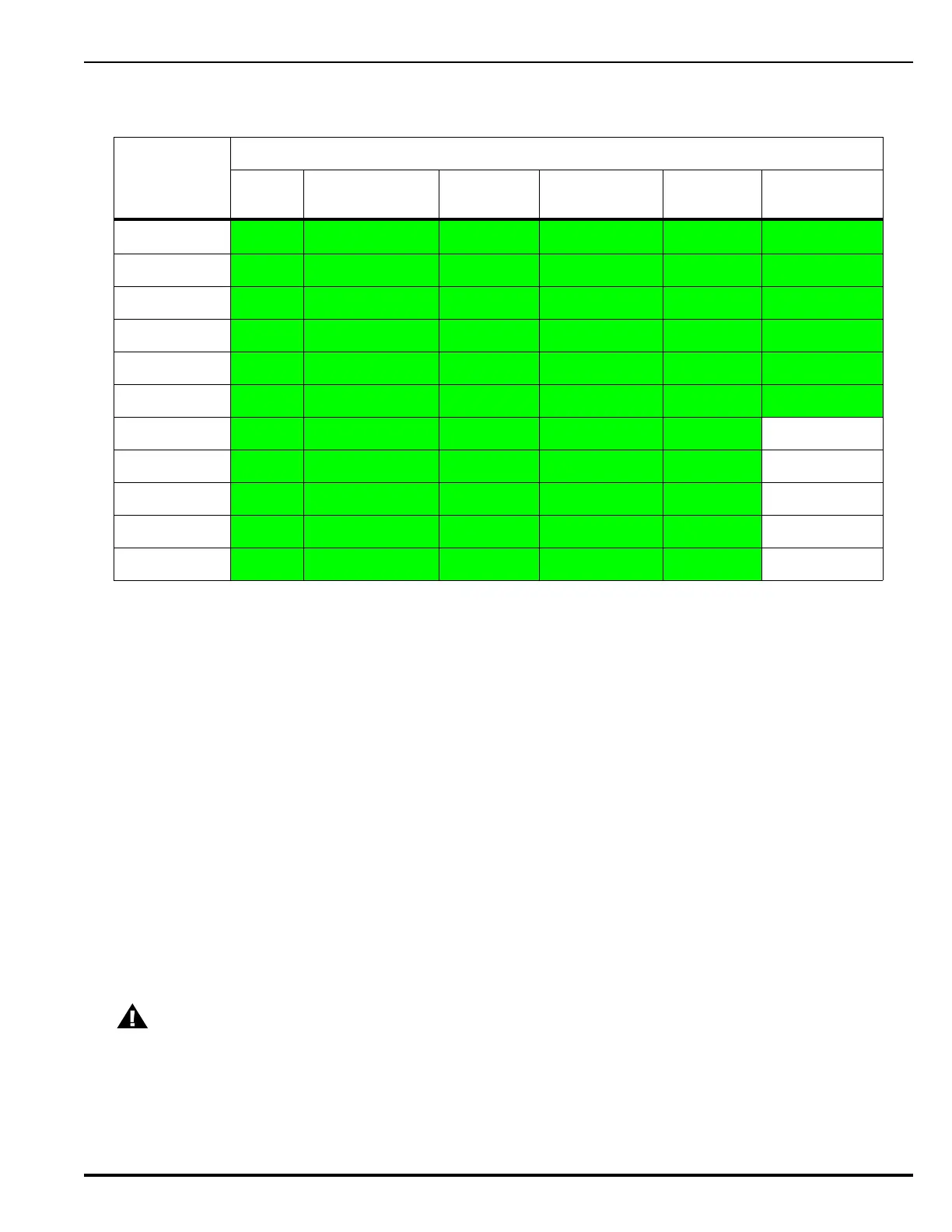

Table 4-13. Allowable Pipe Grade and Size for Use with Kidde IGS Manifold to Selector valves for Sch. 80

Threaded Fitting

NPS Pipe

size

Grade

A-106C

A-106B

A-53B

A-53B

ERW

A-106A

A-53A

A-53A

ERW

A-53F

Furnace

1/4

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

CAUTION

The calculation software has only been verified for use with the piping, inside

pipe diameter and fittings specified in this manual. When unspecified piping and

fittings are used for unbalanced systems, there is a risk that the system will not

supply the required quantity of Agent.

Loading...

Loading...