Installation

April 2020 4-28 06-237619-001

4-8.5 Installation of Pipes

4-8.5.1 Cutting

The required length of pipe is measured and marked on the pipe. The pipe is cut at 90° with a

cutting machine. After cutting, the pipe end shall be reamed and all burrs removed and all

cutting oil shall be removed from both inside and outside of the pipe.

4-8.5.2 NPT/BSPT – Threading

Threads on all pipe and fittings must be tapered threads conforming to ANSI Specification

B-20.1. or ISO 7-1. Joint compound, tape or thread lubricant must be applied only to the male

threads of the joint excluding the first two threads.

Threads shall be cut to the full cutting length as specified in Table 4-15 and Table 4-16 using

a pipe-threading machine. After threading, the pipe shall be cleaned to remove excess cutting

oil and any other particulates.

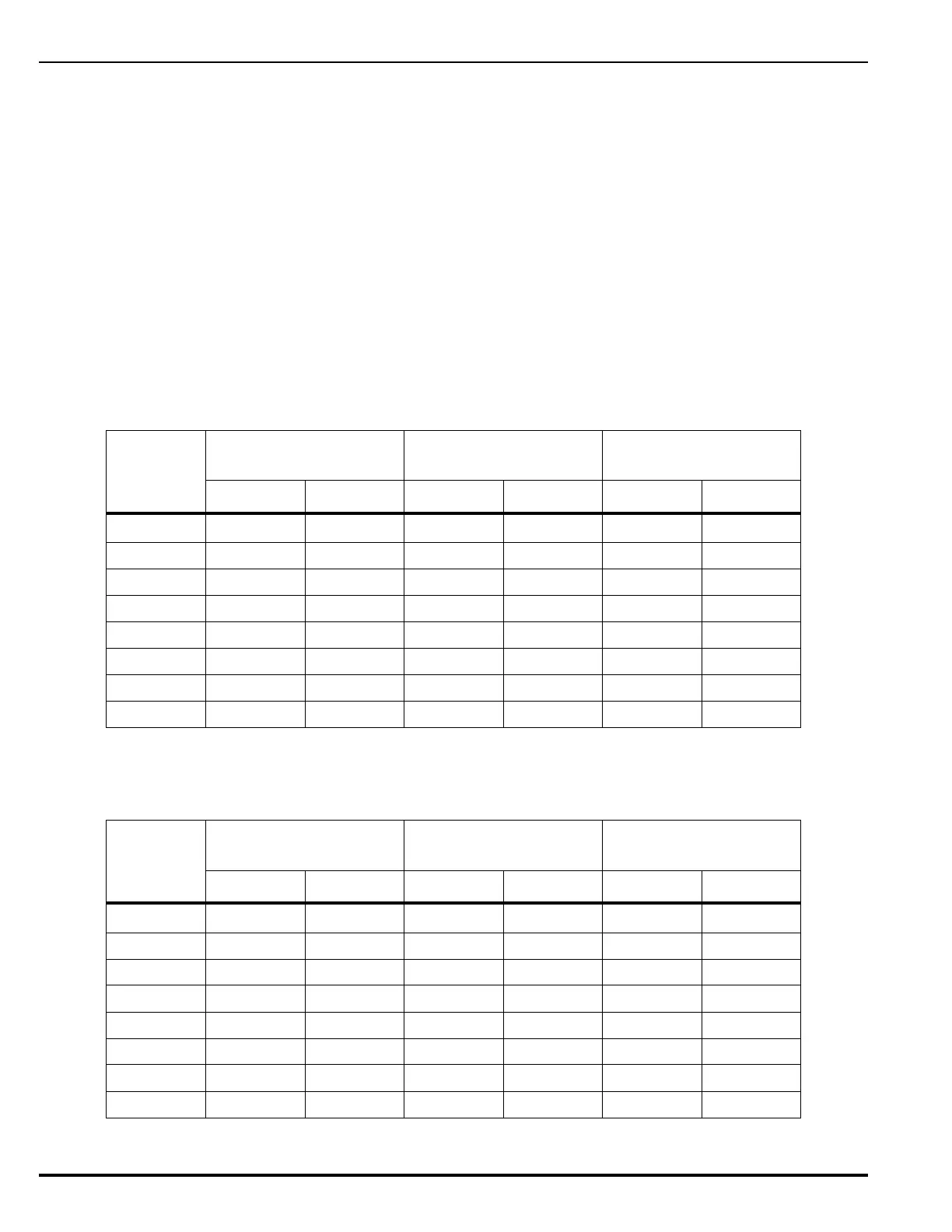

Table 4-15. NPT Thread Length

Pipe

Diameter

Length of

NPT-Thread

Effective Length of

NPT-Thread

Free Length of

NPT- Thread

mm Inches mm Inches mm Inches

1/2” 14.50 0.570 13.56 0.533 0.94 0.037

3/4” 16.00 0.629 13.86 0.545 2.14 0.084

1” 19.00 0.748 17.34 0.682 1.66 0.065

1 1/4” 20.50 0.807 17.95 0.706 2.55 0.100

1 1/2” 20.50 0.807 18.38 0.723 2.12 0.083

2” 22.00 0.866 19.20 0.755 2.80 0.110

2 1/2” 31.00 1.220 29.00 1.141 3.00 0.118

3” 33.50 1.319 30.48 1.200 3.02 0.118

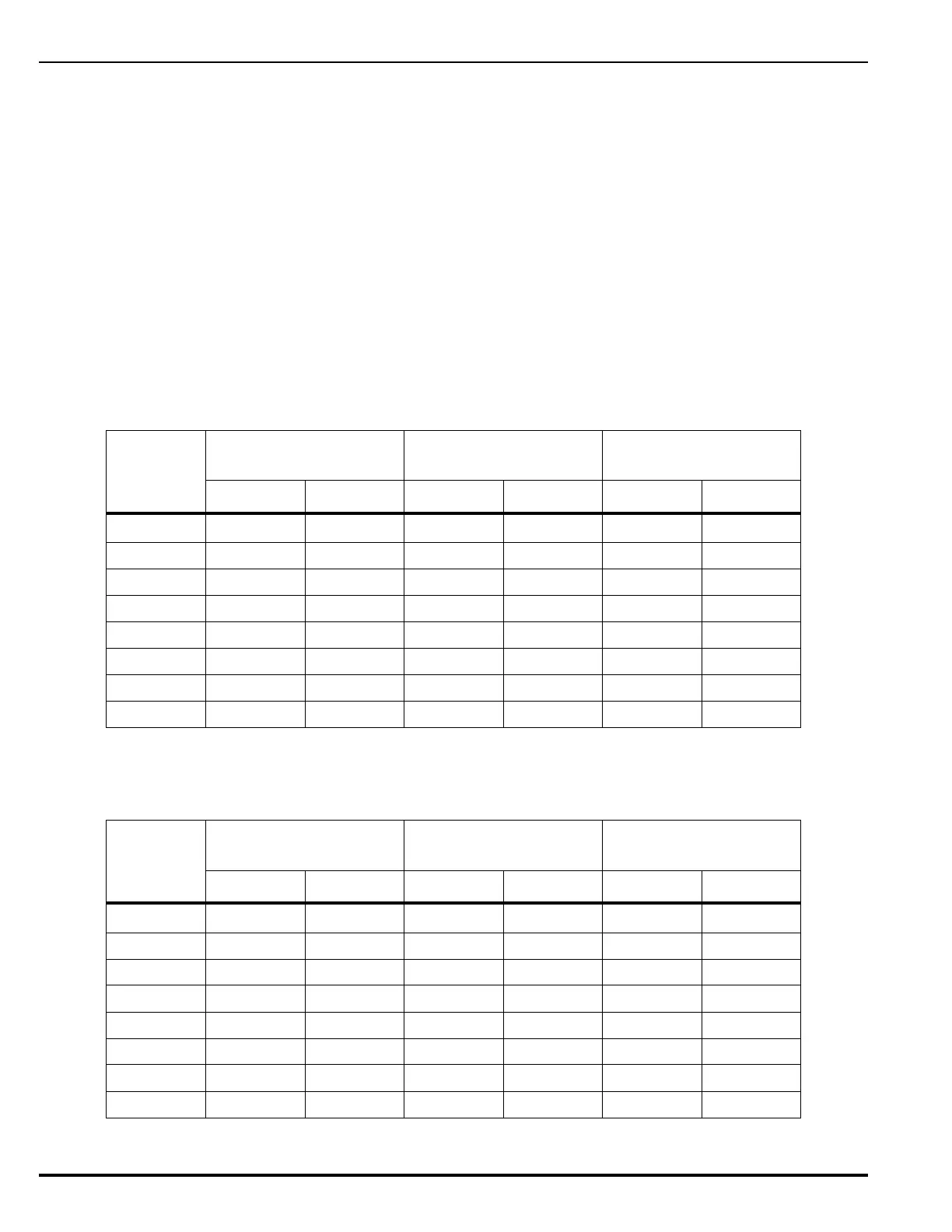

Table 4-16. BSPT Thread Length

Pipe

Diameter

Length of

BSPT- Thread

Effective Length of

BSPT-Thread

Free Length of

BSPT- Thread

mm Inches mm Inches mm Inches

1/2” 14.50 0.570 13.0 0.511 1.50 mm 0.059

3/4” 16.00 0.629 15.0 0.590 1.00 mm 0.039

1” 19.00 0.748 17.0 0.669 2.00 mm 0.078

1 1/4” 20.50 0.807 19.0 0.748 1.50 mm 0.059

1 1/2” 20.50 0.807 19.0 0.748 1.50 mm 0.059

2” 22.00 0.866 20.0 0.787 2.00 mm 0.078

2 1/2” 31.00 1.220 27.0 1.062 4.00 mm 0.157

3” 33.50 1.319 30.0 1.181 3.50 mm 0.137

Loading...

Loading...