Post-Discharge Maintenance

06-237619-001 7-5 April 2020

7-6.3 Nitrogen Pilot Cylinder Recharge

Note: This procedure is for Pilot cylinders only.

Nitrogen Pilot cylinders must be recharged when the cylinder pressure gauge indicates

pressure is 10% below normal (1800 PSIG at 70°F [124 bar gauge @ 21°C] as adjusted for

temperature as shown in Figure 7-2) or immediately after discharge. Nitrogen used for

charging must comply with Federal Specification BB-N-411C, Grade A, Type 1. Copies of this

specification may be obtained from: http://global.ihs.com/

Recharge Pilot cylinders as follows:

1. Remove the protection cap from the cylinder valve actuation port.

2. Install the nitrogen cylinder recharge adapter (P/N WK-933537-000) to the cylinder valve

actuation port and plug valve outlet port with 1/8 in. NPT pipe plug.

Note: The pressure gauge attached to the extinguishing system is not to be used to determine

when the intended charging pressure has been reached.

3. Connect the nitrogen recharging supply hose to the adapter. Tighten securely.

4. Open the nitrogen recharging control valve slowly until full nitrogen flow is obtained.

5. Monitor the recharging supply pressure gauge. Close the charging control valve when the

gauge indicates proper cylinder pressure (1800 PSIG @ 70°F [124 bar gauge @ 21°C]) or

until the mass of nitrogen reaches the number referenced in Table 6-9.

6. Allow the cylinder to cool to ambient temperature and recheck nitrogen cylinder indicated

pressure.

7. Open valve and add additional nitrogen as needed to obtain full cylinder charge at ambient

temperature (1800 PSIG @ 70°F [124 bar gauge @ 21°C]).

8. Close the valve and remove the supply hose and charging adapter from the nitrogen Pilot

cylinder.

9. Check the nitrogen cylinder valve for leakage using a soap solution. Bubbles appearing in

the soap solution indicate leakage and shall be cause for rejection of cylinder.

10. After the leak test is completed, thoroughly clean and dry the cylinder valve.

11. Ensure the cylinder valve control head port is clean and dry.

12. Immediately install the protective cap to the actuation port of the cylinder valve.

13. Install the charged cylinder as directed in Section 4-17.

WARNING

Before recharging, cylinder must be firmly secured by chains, clamps or other

devices to an immovable object such as a wall, structural I-beam or

permanently mounted holding rack.

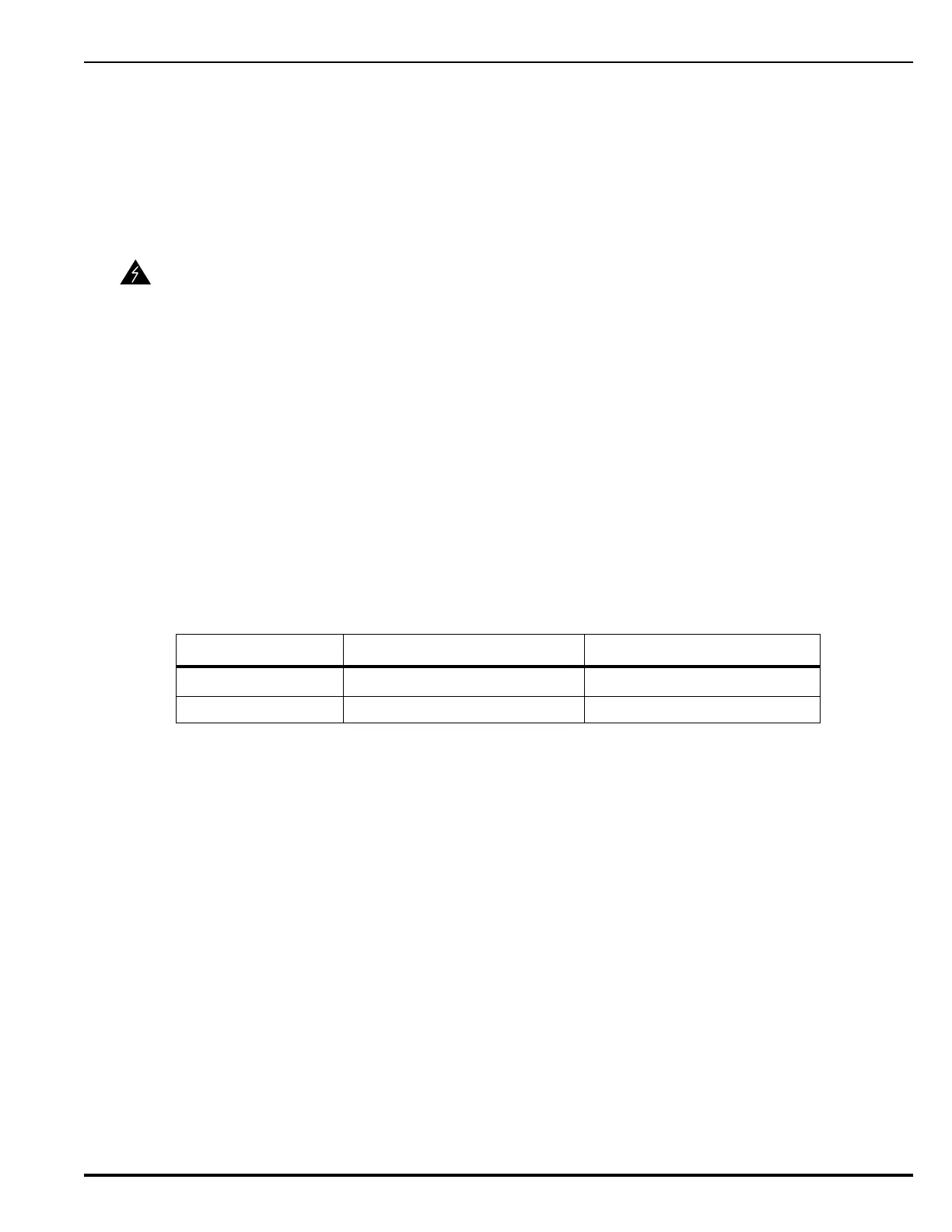

Table 7-1. Nitrogen Fill Weights

Part Number Description Fill Weight (lb.) Nominal

06-129773-001 108 cu. in. nitrogen cylinder 0.52

90-101040-000 1040 cu. in. nitrogen cylinder 5.70

Loading...

Loading...