Installation

April 2020 4-20 06-237619-001

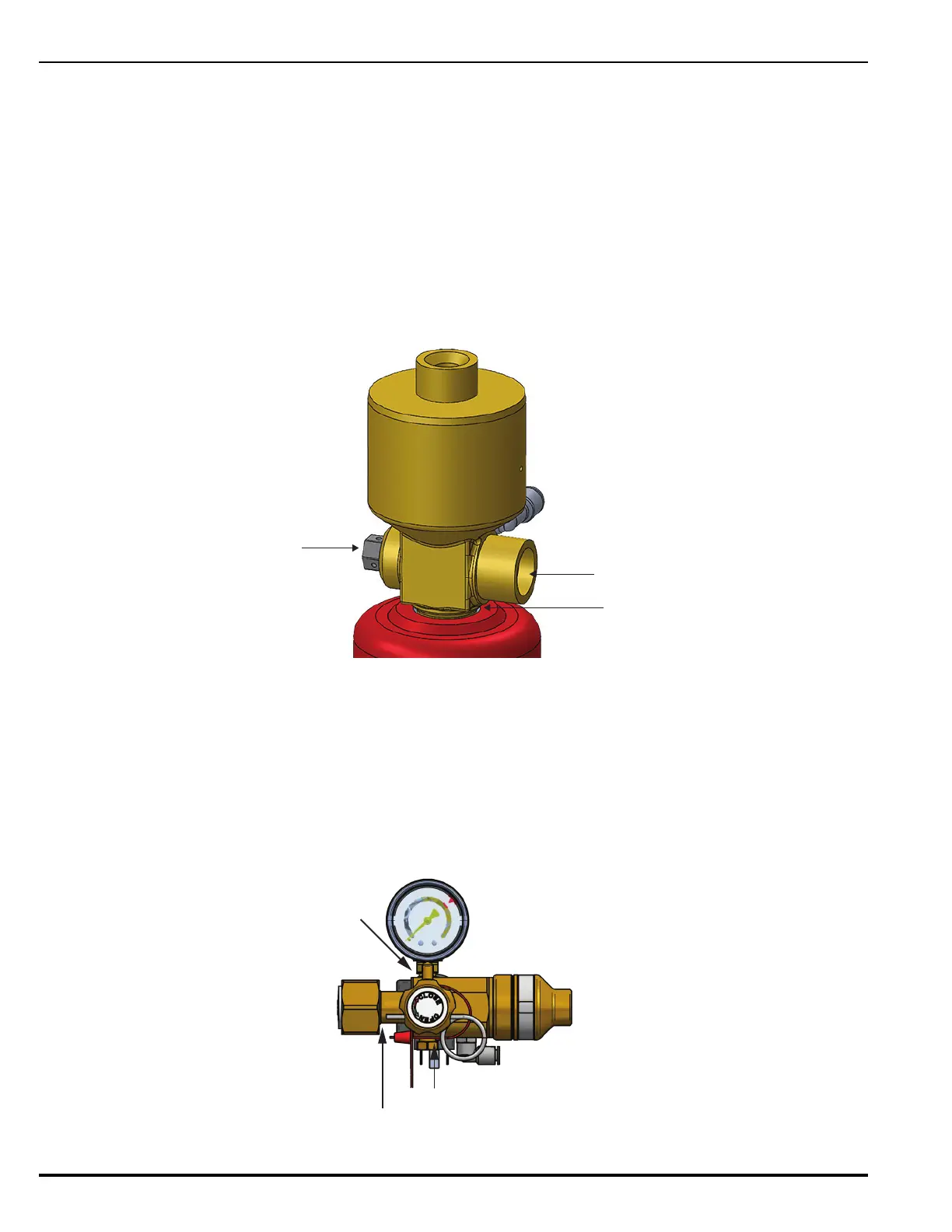

4-6.9 Locations for Leak Testing the Valve and Cylinder

Note: As the system relies on pressure from the cylinders to operate, all permanently pres-

surized connections (or those under pressure during a discharge, including the cylinder

valves) must be checked for leakage during the installation. This check includes actua-

tion and outlet port valve, the gauge connection port on the release unit or cylinder

slave gauge, and the various parts fitted into the contact gauge unit(s) and the pilot

hoses.

Any leakage from the pressure bearing parts may jeopardize the operation of the

system. It is therefore mandatory that the checkpoints listed hereafter are completed

and that the specified torques are applied to the connections.

The arrows on the sketch below indicate locations where to apply ammonium-free leak

detection liquid or spray in order to verify that there are no leaks.

Figure 4-18. Valve Leak Test Locations

Should a leak be found, then fit the safety transport cap and return the cylinder to Kidde Fire

Systems for refurbishment or replacement of valve and refilling.

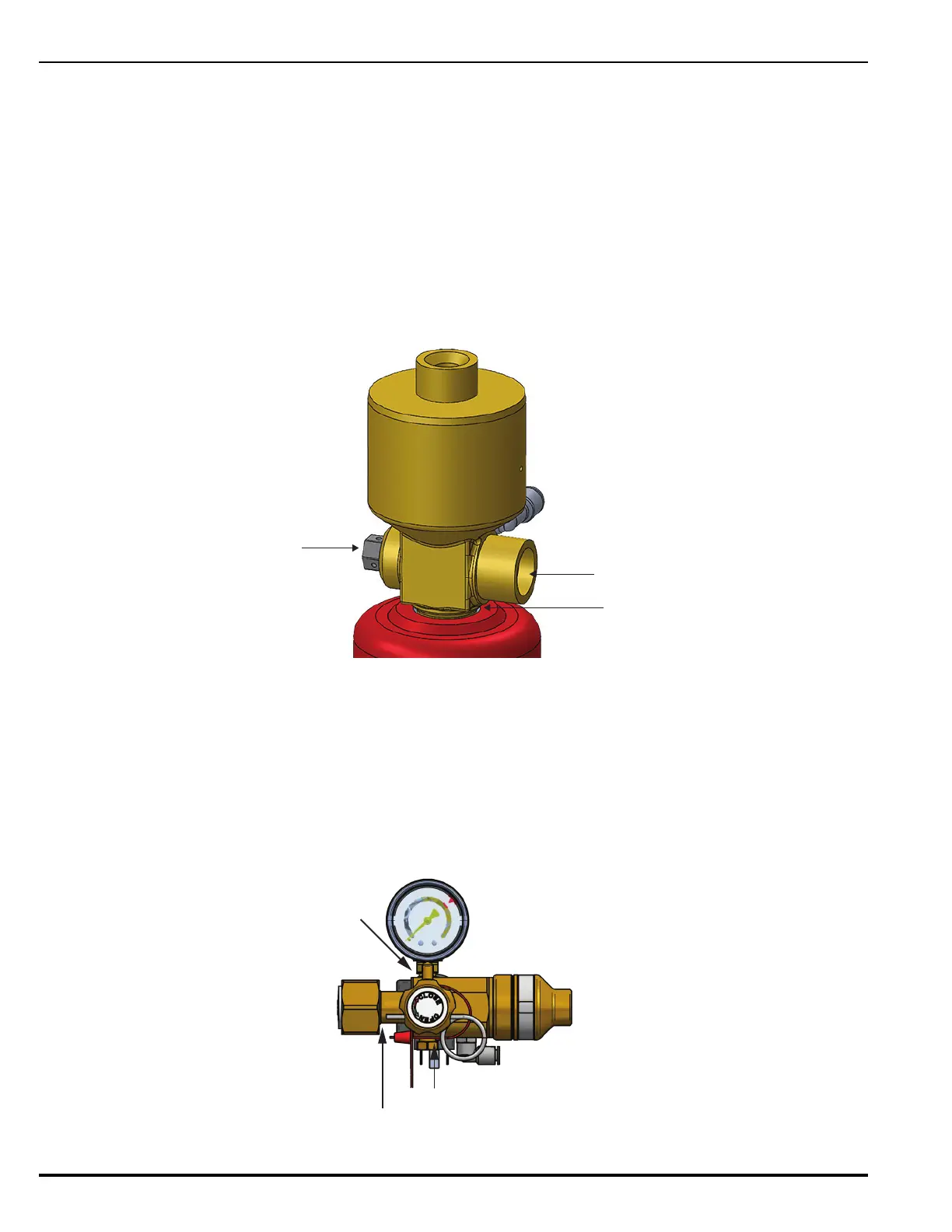

4-6.10 Locations for Leak Testing the Release Unit

The arrows on the sketch below indicate locations where to apply ammonium-free leak

detection liquid or spray in order to verify that there are no leaks. Should a leak be found on

the release unit, the unit shall be dismantled and returned for replacement.

Figure 4-19. Release Unit Leak Test Locations

Loading...

Loading...